Atlas Support

AquaSolve – PVA

Helios Support

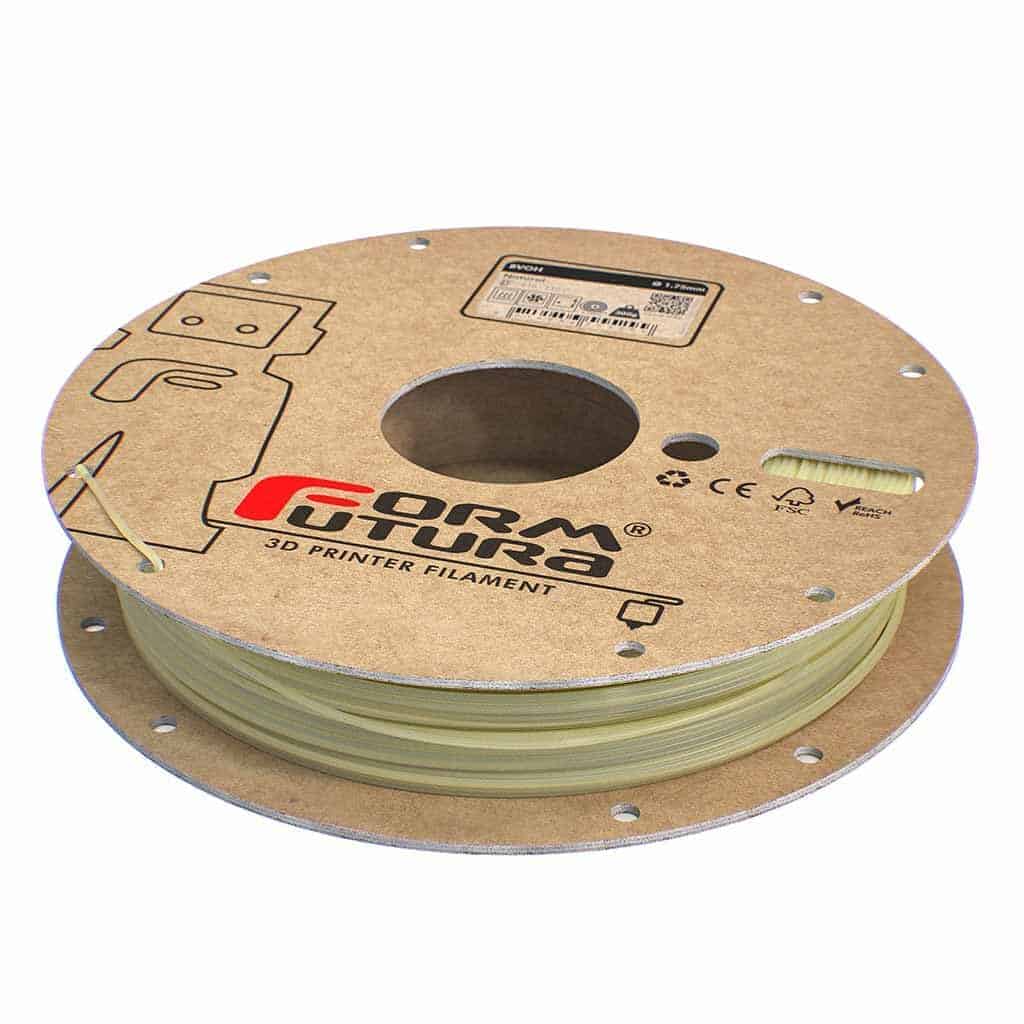

BVOH

PVA filament

What is PVA filament?

PVA stands for polyvinyl alcohol and is a water-soluble plastic that works well as a supporting material for all your 3D printing projects. PVA filament 1kg is suitable for 3D printers that can print with two materials simultaneously. This could either be a dual-feed system or a printer with two extruders.

Because PVA is completely soluble in water after printing, you can use this filament for projects that require precise openings. After the PVA material is dissolved, only the other material (for example ABS or PLA) will be visibly present. This makes PVA great for complex projects.

How to print with PVA filament?

Like all 3D printing filaments, it is important to print at the right temperature. For PVA, this optimum temperature is between 190°C and 210°C. However, this can differ for each printer. Therefore it is important to experiment with different temperatures and/or even do test print to ensure that your projects will look as good as possible.

It is also important to combine PVA filament 1kg with a material that adheres well to it. We recommend ABS and PLA. What's great about PVA as opposed to HIPS filament is that it works with more materials than just ABS filament.

Finally, be careful about using PVA that has already been used before. Because this filament might have already come into contact with air and possibly moisture. This could lead to problems while printing.

What are the advantages and disadvantages of PVA filament?

Advantages

As mentioned earlier, PVA filament is an excellent support material for 3D printing projects where voids or openings are required. This combined with a 3D printer that supports two materials (dual-feed system or two extruders) allows you to print extremely complex projects with PVA as the support material.

In addition, PVA adheres very well to PLA and ABS. For those reasons, we recommend using those materials in combination with PVA.

Lastly, the color of PVA doesn't matter because it is a supporting material anyways and won't be visible once your project is finished. This makes it easier to shop for PVA.

Disadvantages

Due to the fragile properties of PVA (for example, its rapid reaction to water), it is very important that you store PVA properly in an airtight environment. Proper storage of this filament will give you the best results.

Curious about the possibilities with PVA filament 1kg? Check out the FormFutura product range below.

3D BVOH filament

3D BVOH filament, all you need to know

BVOH is a unique 3D printing filament specially made for FDM printers with a very high adhesion to several other filaments such as: ABS, ASA, PLA, PET, PA, PC and TPU. BVOH dissolves very quickly in water and is therefore also easy to print. With BVOH you can print complex models in high quality with ease. This makes it an excellent filament for dual extruder 3D printers. Moreover, BVOH is non-toxic.

3D BVOH filament Support removal

With BVOH, it is very easy to remove the supports after printing. After placing the design in hot water, the support filaments will dissolve completely. This provides a better result than filaments where the supports have to be broken down.

BVOH is best stored in a dry place in a sealed bag. Avoid contact with liquids to ensure that the material remains at its best.

3D BVOH filament applications

BVOH works well in a variety of applications. For example, it is a great material for making working prototypes of your product. This is due to the ease of printing combined with the strength of BVOH.

In addition, BVOH is also suitable for various types of decoration designs. Because BVOH is suitable for complex designs, you can use it to make for example, jewelry. Even with small designs the intricate details will still be visible.

Finally, 3D BVOH filament also works well for moving mechanisms. Because the support filaments dissolve in water, you can print in different ways compared to filaments where you have to break off the supports. This works well for designs where multiple parts move with each other.

What are the advantages and disadvantages of 3D BVOH filament

Advantages:

3D BVOH filament is a great choice for complex structures. Because of its ability to retain small intricate details. It's support filaments can also dissolve in water. Moreover, it is also one of the more environmentally friendly filaments. It's also has a high adhesion to other materials and is resistant to thermal degradation through optimized melt flow properties.

Disadvantages:

BVOH is a great filament but it also comes with some setbacks. It has to be protected from moisture in order to ensure the best results. It is also much more expensive than other filaments.