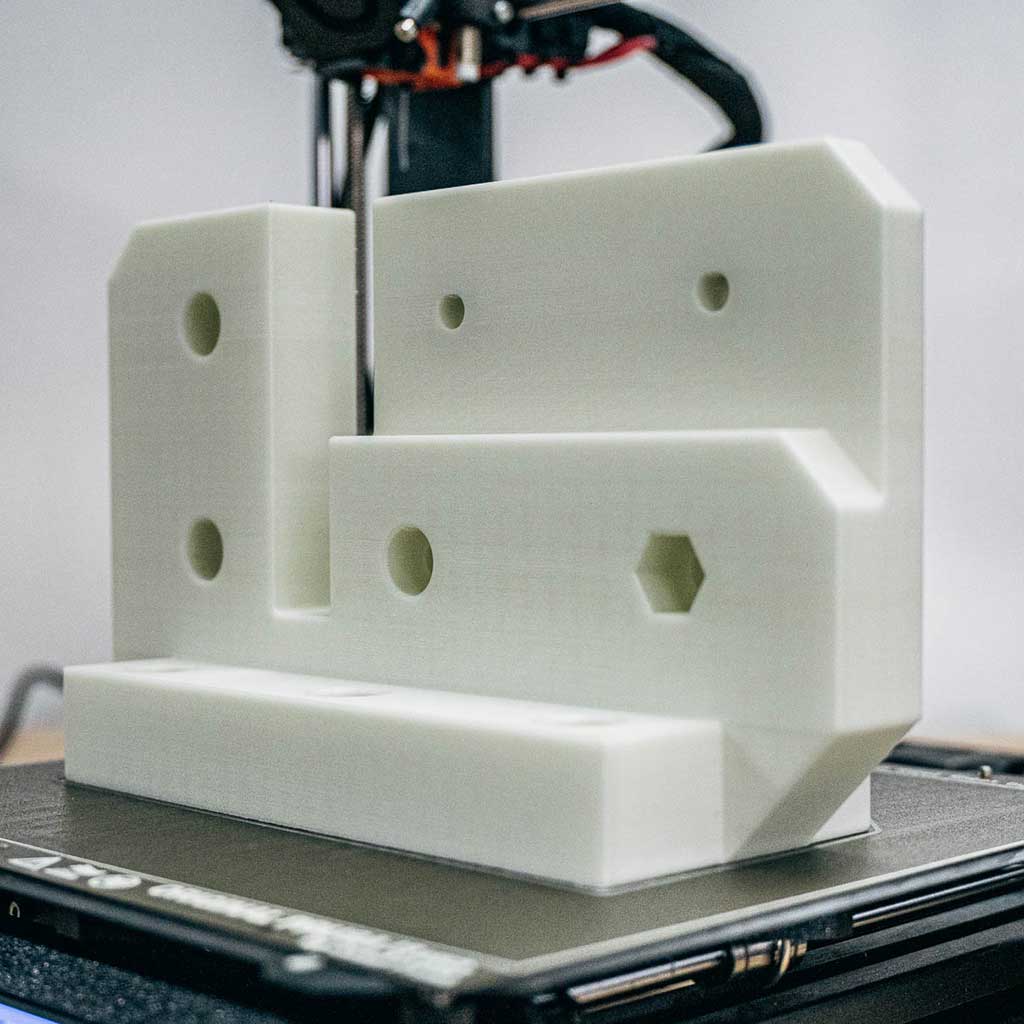

Our Engineering LCD Resin – Ultimate 2TW is a very versatile 3D printing resin. The resin is tough and has a high temperature resistance. Next to this, it exhibits excellent UV and weathering stability. Ultimate 2TW is an impact resistant material comparable to PP. It is a shape-memory resin and bends back when heated over 70C. This resin is an excellent choice for many end-use parts

Important key features

- High toughness and temperature resistance.

- Modulus similar to Polypropylene (PP).

- Excellent UV and weathering stability specs.

- Memory shape capabilities.

- Low skin irritation characteristics.

- Good compatibility with all SLA, DLP and LCD / MSLA 3D printers in the range of 385 – 420nm.

Suitable applications

- 3D printing functional end-use parts.

- Short-run manufacturing.

- 3D printing outdoor parts.

- Manufacturing custom braces and splints.

Physical properties after post curing

This data provided for those properties are typical values, and should not be construed as sales specifications.

Specimen printed in ZXY Orientation (ISO 52921) and examined according to ISO 17296-3.

Please note that the above-displayed values can vary with individual machine processing, post-curing parts, geometry, print orientation, print settings, and temperature.

Specimens have been post-cured for 30 minutes with 200W and 405nm UV LED conditioned for 72 hours at 23°C and 50% humidity.

Preparation(s) before starting to print

- Shake the bottle for at least 2 minutes before each use.

- After shaking the bottle, leave the resin to rest for 10 minutes to let air bubbles get out of the resin

- The resin can be poured back from the vat into the bottle once your print is finished

- Always use protective measurements like safety glasses and nitrile gloves when handling resins.

Post-processing

- We do advise you to post-process your 3D print in order to achieve the material properties

- Rinse your 3D printed object in IPA or (Bio)Ethanol for approximately 5 minutes

- An ultrasonic cleaner is preferred/recommended

- Make sure that IPA and/or (Bio)Ethanol rinsed objects are perfectly dry before further post-curing

- Place the rinsed parts in a well-ventilated area for at least 30 minutes, or use pressurized air for at least 2 minutes

- Cure your object in a high power curing chamber for approximately 20-30 minutes at 65° C

- The preferred curing wavelength is between 300-410nm

Safety

Please always be aware that when 3D printing with resins that you are working with chemicals and that you should always be cautious and use the personal protective equipment as stipulated in our safety data sheets.

- Always wear Respiratory Protection when sanding/cutting the resin object.

- Always use nitrile gloves when handling resins and uncured resin objects.

Product export information

| HS Code: 29161400 | Description: Resin for 3D Printing | Country of origin: European Union |

Safety Datasheet: