We are excited to announce that as of June 2020 ReForm rPET has been adopted into the Ultimaker Material Alliance Program (UMAP). This is a big milestone for FormFutura as while this is not our first product joining the program, ReForm rPET is the first fully recycled filament to join – and we are really excited about that.

The Ultimaker Material Alliance Program

All materials adopted in the UMAP come with printing profiles that will be available on the Cura Marketplace, dedicated to specific Ultimaker 3D printers. Through these readily accessible printing profiles, processes like switching configurations for materials and starting prints become more streamlined and user-friendly.

As the 3D printing industry is growing and evolving and FormFutura is evolving with it, with one of our primary goals being to offer users a complete and efficient printing solution. A solution in which hardware, software, and printing materials are in tune with each other and are greatly optimized. Participating in the Ultimaker Partner Alliance Programs is a development that perfectly aligns with that goal.

Over its 8 years, FormFutura has grown its portfolio from offering PLA and ABS filaments to offering more than 2000 products. If there is anything we have learned during all this growth, it’s that innovation should – and needs to – come from every direction. As a leading 3D printing materials provider, it is our belief that we are responsible for streamlining the interaction between our products and the production process.

By the way, did you know that multiple FormFutura products are already a part of the program? Here is a shortlist of the products that are currently participating and have printing profiles available in the Cura Marketplace:

EDIT: ReForm rPLA is now also adopted into the program and its printing profile is available in the Cura Marketplace.

Want to use one of the printing profiles immediately?

You can find them in the Cura Marketplace

ReForm products

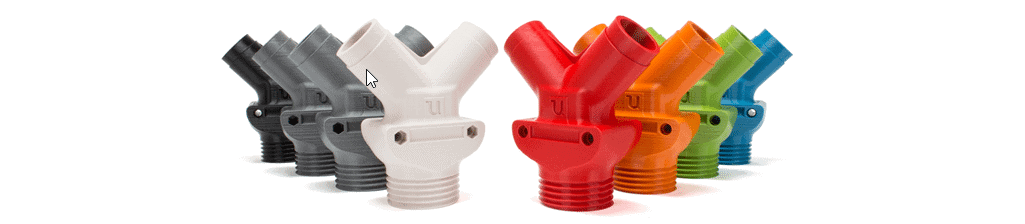

All ReForm products are produced from recycled material. ReForm rPET is made from the post-processing waste of a local bottle manufacturer, while rPLA and rTitan are made from filament production waste. As a rule of thumb, our ReForm brand is all about repurposing production waste and upcycling it to produce filaments without sacrificing on print quality.

Image: A visualization of the production cycle of ReForm rPET filament.

Want to learn more about our ReForm products or simply curious what all the fuzz is about? Click here to learn more and explore the filaments for yourself.

A sustainable endeavor

While the adoption of ReForm products into the program helps us enable you to have easier access to the sustainable filament brand, there are more ways in which we promote conscious and sustainable choices.

For example: in the summer of 2019 we moved to sustainable packaging for all filament with up to one kilogram. The filaments are spooled onto fully recyclable and sturdy cardboard spools, which are FSC certified. In addition to that, the filament boxes are made from recycled cardboard as well.

One-kilogram cardboard spools are just the beginning. We are currently testing to see if 2.3kg filament spools are feasible – which looks promising – and our goal is to extend that to cardboard spools supporting filaments of up to 4.5kg.

There are a couple of reasons why we felt compelled to switch to cardboard packaging:• It fits our vision to develop FormFutura to be a sustainable company• It is recyclable, meaning it can easily be arranged via existing paper recycling programs• Cardboard is a natural desiccant (drying agent) so cardboard spools are better at protecting your filament against humidity• Unlike plastic spools, cardboard spools run no risk of deformation when a user needs to pre-dry filament• It is manufactured locally which helps reduce our carbon footprint• It’s got style, we want to raise awareness for similar businesses and end users alike – and show that making a sustainable choice like using cardboard packaging is not only the more responsible choice but has other benefits as well

We are proud that all FormFutura materials included in the Ultimaker Material Alliance Program are available in our signature cardboard spools and we are hopeful that filament will become widely available on bigger cardboard spools.