Introducing: High Speed Filaments

Promising and Challenging

3D printing, often hailed as a groundbreaking and transformative technology, has captivated the imagination of innovators and industry enthusiasts alike. Mention 3D printing in a room filled with makers, creators, and engineers, and you’re sure to get plenty of enthusiasm about its potential possibilities and various applications. The excitement surrounding this technology is palpable, and for a good reason – it promises to revolutionize the way we approach production. Still, amid the anticipation that 3D printing generates, there is still some hesitance among producers and prospective end-users to fully embrace it as a standard practice. Over the years, significant strides have been made in improving the quality of printed objects and enhancing the user-friendliness of 3D printers.

“It just takes too long”

There’s one enduring issue that continues to frustrate many: the extensive period of time it takes to bring 3D creations to life. Manufacturers have diligently worked to elevate the industry’s standards by introducing faster printing options, and they’ve made commendable progress. Regardless, reliable and speedy 3D printing, particularly at rates exceeding 100mm/s, has remained somewhat of an elusive goal. The common lament has been, “It just takes too long.” The good news is that a long-anticipated solution has emerged, effectively turning the concept of “high-speed 3D printing” from a distant dream into a tangible reality. Now printing reliably at speeds of 400mm/s, and some even managing printing speeds of up to 2000mm/s. 3D printing really has entered the next phase. What’s most remarkable is that it is also affordable for end-users, marking a significant turning point in the world of 3D printing technology.

In this post, we will explore the use of high-speed filaments and how FormFutura intends to play an integral part in offering many materials that will transform the landscape of 3D printing, making fast and reliable printing accessible to all.

Speed without losing precision.

High speed 3D printing: How it works

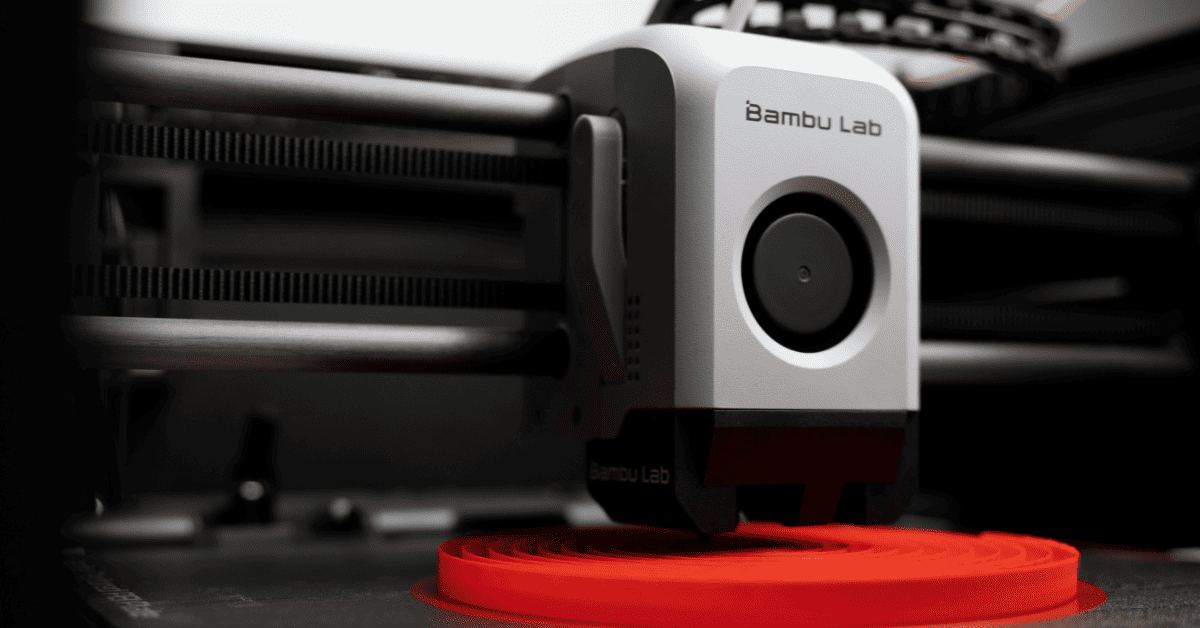

High-speed 3D printing follows the same basic additive manufacturing process as traditional 3D printing. It builds objects layer by layer, adding material one thin layer at a time to create the final 3D structure. However, the key to high-speed printing lies in optimizing each step of this process for efficiency. High-speed 3D printers are designed to rapidly and precisely deposit this material, minimizing the time taken to build each layer. Typically, how this result is achieved is by having a shorter heat zone in the extruder. This design reduces the time it takes for the filament to reach the desired melting point and flowability. A shorter heat zone allows for quicker response to changes in temperature and material flow.

Finding the right temperature

The temperature control also requires improvements as it needs to be more responsive and precise in high-speed extruders. This ensures that the material is maintained at the correct temperature for extrusion, even during rapid changes in extrusion speed. Naturally, this will also require better cooling systems to rapidly cool the material after extrusion. Cooling is crucial to ensure that the material solidifies quickly, particularly at higher speeds.

New and faster extruders

For further extruder capabilities, these printers feature a motor with higher torque capabilities. This extra torque provides the force needed to push the filament through the nozzle at faster rates, even when the material is more viscous. You could think that these capabilities would make the extruder heavier, but keeping the weight of the extruder is one of the most crucial parts to having fast printing capabilities. Particularly having reduced mass and inertia allow for faster directional changes without compromising accuracy or print quality. High-speed extruders are engineered to retract and restart filament more rapidly. This feature is crucial for preventing oozing and stringing during rapid travel moves and layer changes, maintaining print quality at high speeds.

These modifications allow the extruder to handle higher flow rates and meet the demands of fast 3D printing without compromising print quality or material integrity. While high-speed extruders are optimized for speed, they are versatile and can be used for a wide range of 3D printing applications.

Supplying High Speed 3D Printing Filaments

While the technology now allows for printers to print at rapid speeds. This really is still not enough when it comes to producing high quality prints at high speed. In the end it does come down to the quality and print consistency of the material you are using.

At FormFutura we've been hard at work to make sure we have plenty of choices when it comes to high speed printing compatibility. To ensure better flowability for something like high speed 3D printing, several additional measures and modifications had to be implemented beyond the basic filament production process. This was mainly focused on optimizing flow characteristics by adjusting the melt flow index and therefore preventing issues like clogging, stringing, or uneven extrusion.

FormFutura also recognizes that high-speed 3D printing relies heavily on the right choice of filament materials. We currently offer different PLA, ABS, and ASA variants specifically engineered to excel in fast and reliable 3D printing. Focusing first on these 3 types of materials, we ensure that there is a wide variety of applications that are available with our high speed filaments.

PLA

Still being the go-to material for many producers and end-users alike, PLA like in any 3D printing material catalogue, still has the most choice when it comes to high speed 3D printing. PLA stands out as a favorable choice due to its low melting point and excellent layer adhesion.

The filament's ability to quickly solidify during the printing process allows for increased printing speeds without sacrificing print quality. This makes PLA a preferred option for those seeking efficient and rapid prototyping or production, as it enables the creation of intricate designs at a faster pace while maintaining the reliability and versatility associated with PLA filament.

Because of this, most PLA kinds in our assortment are also compatible with high speed printing.

ABS

Another well known filament, ABS, or acrylonitrile butadiene styrene filament. This material is known for its durability and heat resistance.

When it comes to high-speed printing, ABS presents unique challenges due to its higher melting point and slower cooling characteristics compared to PLA.

While high-speed printing with ABS can be more demanding, thanks to our Polycarbonate enforcement, however. High speed printing is now possible with our ABSpro range. The higher melting point allows PC reinforced ABS to withstand elevated printing speeds, and the slower cooling process can be managed with appropriate equipment.

This filament's resilience and impact resistance make it a valuable choice for applications where durability is paramount, even in scenarios where high-speed printing is required.

ASA

Least known amongst our high speed filaments. ASA is steadily gaining popularity in the realm of 3D printing for its enhanced UV resistance and weathering properties, making it our general recommendation for outdoor applications.

While not as common as PLA or ABS, ASA also offers advantages for high-speed printing. Its thermal properties, similar to ABS, allow for faster printing speeds without compromising structural integrity.

Filaments which are ASA based show incredible resistance to the elements, making them suitable for rapid prototyping or production of outdoor components, where both speed and durability are essential. ApolloX, which is a range of ASA based filaments that FormFutura offers. Have been manufactured with the vision of high speed printing in mind.

As technology continues to advance, this filament range emerges as a viable option for those seeking both high-speed printing capabilities and reliable performance in challenging environmental conditions.

The Future of High-Speed Printing

There are still many materials that do not support high speed printing, the development and expansion of the different types of polymers into high speed printing is essential for the future. The widespread adoption and continual innovation of high-speed 3D printing holds significance for many different reasons.

At the forefront lies its efficiency, a transformative attribute that speeds up the production of prototypes, components, and various products. This increased efficiency emerges as an essential component for industries where the speed of bringing products to the market plays an important role. The accelerated pace of rapid prototyping and production cycles not only facilitates quicker product development but also orchestrates a reduction in lead times, reshaping the conventional trajectory of manufacturing processes.

Beyond speed, the ramifications of high-speed 3D printing extend into the realm of productivity, affording industries, especially those that are essential like healthcare and aerospace, a surplus of resources. This surplus is not merely confined to standard assets but brings with it an even more important factor, time. With the temporal dividend, industries not only meet pressing demands more effectively, but also carve out space for innovative endeavours in sectors traditionally associated with standard manufacturing.

Another important factor which can be forgotten when it comes to the importance of high-speed 3D printing lies in its potential for cost savings and waste reduction. The acceleration in printing speeds translates into clear economic benefits by lowering labor hours, minimizing energy consumption, and mitigating overall production costs. As this technology traverses the trajectory toward mainstream acceptance, the confluence of economies of scale and streamlined processes promises to fortify the cost-effectiveness even further. This economic efficiency goes seamlessly with the strong emphasis on sustainability, a cornerstone of corporate responsibility in today's business landscape.

In a time where sustainability and further environmental efforts are ongoing, the tandem of high-speed 3D printing and material advancements emerges as a powerful force in the effort against large amounts of waste. The precision and efficiency afforded by this technology not only meet the demands of accelerated production but also can provide significant changes for sustainability goals. This synergy between rapid production and resource optimization has the potential to significantly minimize waste in the manufacturing process, taking a proactive stance toward ecological processes.

The twin pillars of mainstream adoption and perpetual innovation in high-speed 3D printing usher in a transformative era marked by increased efficiency, substantial cost savings, and altered competitiveness across diverse industries. The resultant landscape is one that puts the emphasis on agility and is one that will propel manufacturing and product development into realms which the world has never seen before.