High Speed Compatible 600mm/s

High Speed Compatible 600mm/s

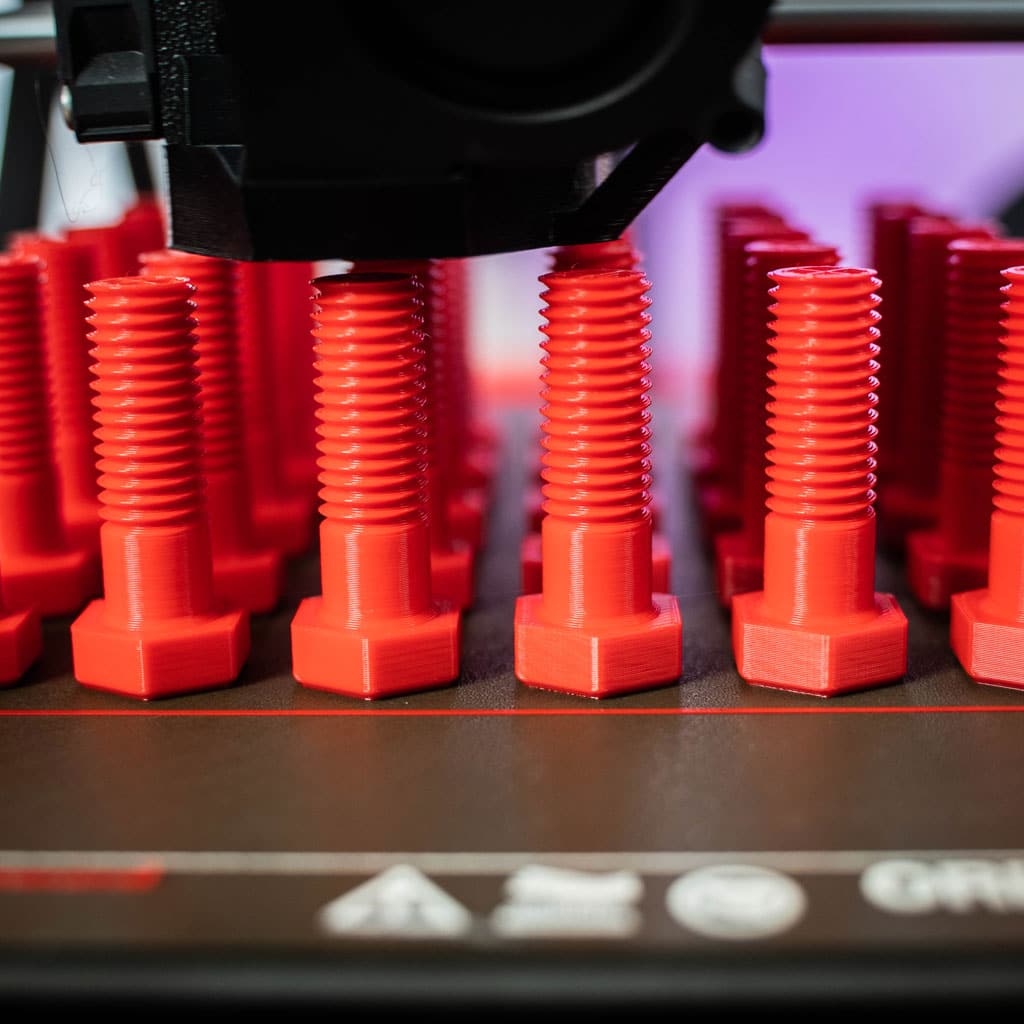

With high speed 3D printing becoming more prominent due to the introduction of high speed 3D printers, FormFutura is excited to introduce a range of new and existing upgraded materials to our assortment. These materials, while still suitable for traditional printers, have also been fully optimized for the new high speed 3D printing technology. Do keep in mind that faster print speeds also require higher print temperatures.

High Precision PLA

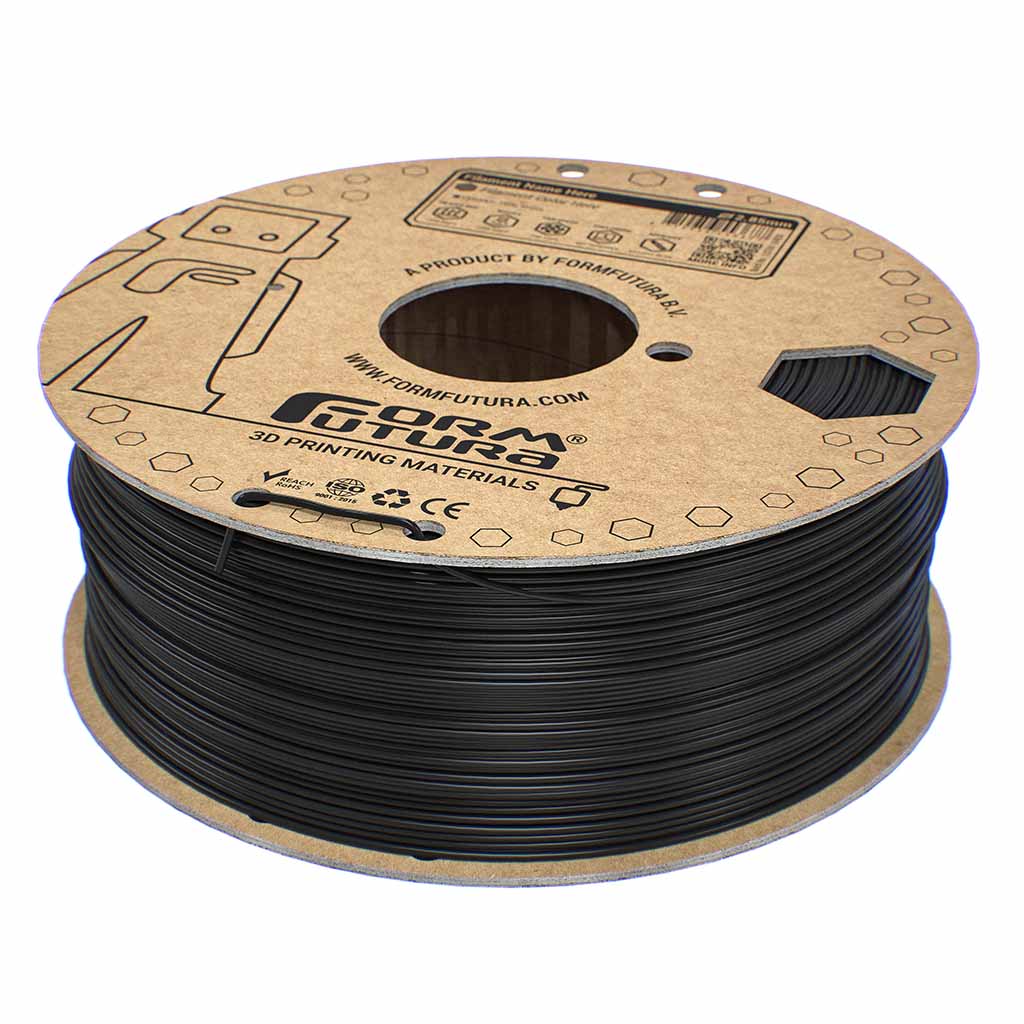

High Precision PLA is a more dense and resilient PLA filament that is developed for consistent batch-to-batch production. The filament has guaranteed precision on diameter, ovality, shrinkage, and color tolerances. The diameter and ovalness of High Precision PLA filament are measured via a continuous 3-axis laser measurement. A 3-axes measurement is far more accurate and ensures that there are no blind spots around the diameter. High Precision PLA filaments are RAL-color matched.

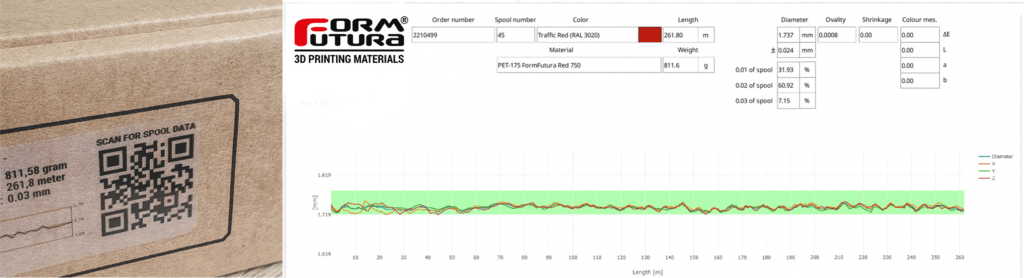

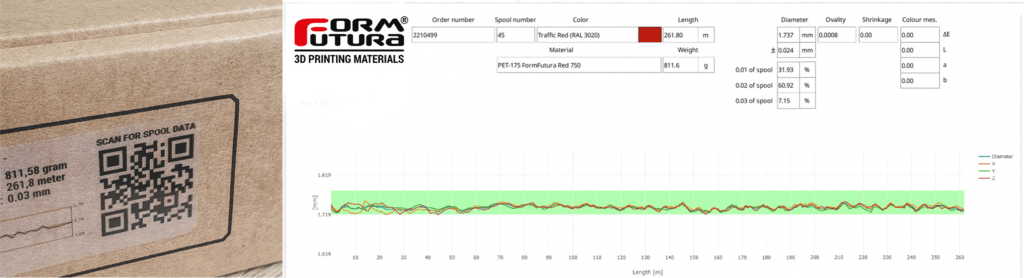

Every spool comes with its individual measurement report. This information can be viewed by scanning the QR code on the spool.

Important key features

- 3-axes filament measurement to ensure the tightest diameter and ovality tolerances.

- Tolerance of ± 0,03 mm for the 1.75 mm diameter filament.

- Tolerance of ± 0,06 mm for the 2.85 mm diameter filament.

- Precise batch-to-batch color consistency (≤ Delta E5).

- Denser and more resilient than traditional PLA filaments.

- 3D prints details with high precision and high surface quality.

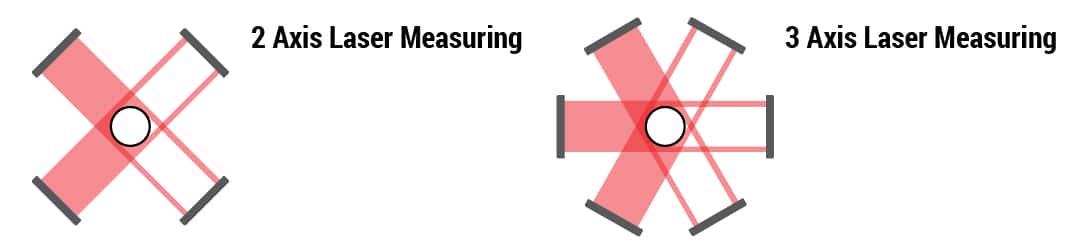

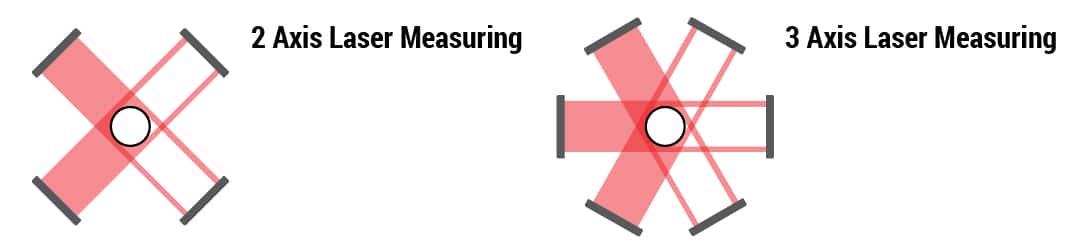

3-axis laser measurement

By using laser measuring from 3 different angles we are able to not only produce a highly accurate 1.75mm diameter filament, but also ensure the roundness of the filament. During this process, the filament is continuously measured and any deviations from the desired diameter are automatically corrected.

We are using a laser micrometer, this type of sensor uses a laser beam to measure the diameter of a material as it passes through the sensor. The laser micrometer sends the measurement data to a control system, which compares the measured diameter to the desired diameter. If a deviation is detected, the control system sends a signal to the equipment. This process can improve the quality and consistency of the material being produced, by reducing variations in diameter and ensuring that the material meets the desired specifications. The device measures on 3 axis as shown on the image above. This has a reduced blind spot compared to 1 or 2 axis measurement which are more standard in the industry.

Precise RAL color matching

RAL is a color matching system used to define standard colors for paint, coatings, and plastics. The system was developed by the German RAL (Reichsausschuss für Lieferbedingungen und Gütesicherung) in 1927 and is now used worldwide. The RAL color system includes more than 2,000 standardized colors, each identified by a unique four-digit code. The colors are divided into six color families: RAL Classic, RAL Design, RAL Effect, RAL Plastics, RAL Digital, and RAL Next. The RAL color system uses a variety of methods to measure and specify colors, including visual color matching, spectrophotometry, and colorimetry.

Visual color matching is the most common method used in the RAL color system. This method involves comparing a sample of the color to be matched with a set of standard RAL color swatches under controlled lighting conditions. The color swatch that most closely matches the sample is then assigned the corresponding RAL color code. Using a more precise method of measuring color that involves analyzing the color of a sample using a spectrophotometer. This instrument measures the amount of light reflected or transmitted by a sample at different wavelengths, and generates a spectral curve that can be compared to the standard RAL spectral curves to determine the closest match.

Color consistency

By keeping to the RAL color so diligently we of course also have exceptional color consistency in our filament. For measuring of object color we used color space defined by the International Commission on Illumination (abbreviated CIE). Color is measured by spectrophotometer with geometry d/8° and diameter of hole 8 mm. Measurements is performed at the D65 with 10° observer.

Retrieve your filament data by using the QR code

By scanning the QR code on the package of the filament you will be able to view all critical information from your purchase. This includes: order number, spool number, RAL color, filament length, material, and weight.

General printing guidelines*

| Nozzle size: ≥ 0.1mm | Layer height: ≥ 0.05mm | Enclosure needed: No |

| Print temp: ± 200 – 220° C | Fan speed: 50-100% | Experience level: Beginner |

| Heat bed: ± 50 – 60° C | Adhesive: EasyFil Nr. I |

*) Above displayed settings are meant as guidance to find your optimal print settings. These ranges in settings should work for most printers,

but please do feel free to experiment outside these ranges if you think it is suitable for your printer. There are a lot of different type of printers,

hot-ends and printer offsets that it is extremely difficult to give an overall one-size-fits-all setting.

Safety Datasheet:

High Precision PLA

A dense and resilient PLA filament with guaranteed “High Precision” on diameter, ovalidity, shrinkage, and color tolerances. Each spool has its own certificate of analysis, which can be verified by scanning the QR code.

- Ordered before 15h CET? Ships same business day

- Worldwide shipping with UPS & FedEx

- One-stop shop for 3D printing materials

Featured Products

High Precision PLA

A dense and resilient PLA filament with guaranteed “High Precision” on diameter, ovalidity, shrinkage, and color tolerances. Each spool has its own certificate of analysis, which can be verified by scanning the QR code.

If a product is out of stock, it is usually replenished within two weeks.

- Ordered before 15h CET? Ships same business day

- Worldwide shipping with UPS & FedEx

- One-stop shop for 3D printing materials

High Speed Compatible 600mm/s

High Speed Compatible 600mm/s

With high speed 3D printing becoming more prominent due to the introduction of high speed 3D printers, FormFutura is excited to introduce a range of new and existing upgraded materials to our assortment. These materials, while still suitable for traditional printers, have also been fully optimized for the new high speed 3D printing technology. Do keep in mind that faster print speeds also require higher print temperatures.

High Precision PLA

High Precision PLA is a more dense and resilient PLA filament that is developed for consistent batch-to-batch production. The filament has guaranteed precision on diameter, ovality, shrinkage, and color tolerances. The diameter and ovalness of High Precision PLA filament are measured via a continuous 3-axis laser measurement. A 3-axes measurement is far more accurate and ensures that there are no blind spots around the diameter. High Precision PLA filaments are RAL-color matched.

Every spool comes with its individual measurement report. This information can be viewed by scanning the QR code on the spool.

Important key features

- 3-axes filament measurement to ensure the tightest diameter and ovality tolerances.

- Tolerance of ± 0,03 mm for the 1.75 mm diameter filament.

- Tolerance of ± 0,06 mm for the 2.85 mm diameter filament.

- Precise batch-to-batch color consistency (≤ Delta E5).

- Denser and more resilient than traditional PLA filaments.

- 3D prints details with high precision and high surface quality.

3-axis laser measurement

By using laser measuring from 3 different angles we are able to not only produce a highly accurate 1.75mm diameter filament, but also ensure the roundness of the filament. During this process, the filament is continuously measured and any deviations from the desired diameter are automatically corrected.

We are using a laser micrometer, this type of sensor uses a laser beam to measure the diameter of a material as it passes through the sensor. The laser micrometer sends the measurement data to a control system, which compares the measured diameter to the desired diameter. If a deviation is detected, the control system sends a signal to the equipment. This process can improve the quality and consistency of the material being produced, by reducing variations in diameter and ensuring that the material meets the desired specifications. The device measures on 3 axis as shown on the image above. This has a reduced blind spot compared to 1 or 2 axis measurement which are more standard in the industry.

Precise RAL color matching

RAL is a color matching system used to define standard colors for paint, coatings, and plastics. The system was developed by the German RAL (Reichsausschuss für Lieferbedingungen und Gütesicherung) in 1927 and is now used worldwide. The RAL color system includes more than 2,000 standardized colors, each identified by a unique four-digit code. The colors are divided into six color families: RAL Classic, RAL Design, RAL Effect, RAL Plastics, RAL Digital, and RAL Next. The RAL color system uses a variety of methods to measure and specify colors, including visual color matching, spectrophotometry, and colorimetry.

Visual color matching is the most common method used in the RAL color system. This method involves comparing a sample of the color to be matched with a set of standard RAL color swatches under controlled lighting conditions. The color swatch that most closely matches the sample is then assigned the corresponding RAL color code. Using a more precise method of measuring color that involves analyzing the color of a sample using a spectrophotometer. This instrument measures the amount of light reflected or transmitted by a sample at different wavelengths, and generates a spectral curve that can be compared to the standard RAL spectral curves to determine the closest match.

Color consistency

By keeping to the RAL color so diligently we of course also have exceptional color consistency in our filament. For measuring of object color we used color space defined by the International Commission on Illumination (abbreviated CIE). Color is measured by spectrophotometer with geometry d/8° and diameter of hole 8 mm. Measurements is performed at the D65 with 10° observer.

Retrieve your filament data by using the QR code

By scanning the QR code on the package of the filament you will be able to view all critical information from your purchase. This includes: order number, spool number, RAL color, filament length, material, and weight.

General printing guidelines*

| Nozzle size: ≥ 0.1mm | Layer height: ≥ 0.05mm | Enclosure needed: No |

| Print temp: ± 200 – 220° C | Fan speed: 50-100% | Experience level: Beginner |

| Heat bed: ± 50 – 60° C | Adhesive: EasyFil Nr. I |

*) Above displayed settings are meant as guidance to find your optimal print settings. These ranges in settings should work for most printers,

but please do feel free to experiment outside these ranges if you think it is suitable for your printer. There are a lot of different type of printers,

hot-ends and printer offsets that it is extremely difficult to give an overall one-size-fits-all setting.

Safety Datasheet: