Interview with X-LED

In the ever-evolving world of lighting solutions, X-LED Technology stands out as a leader in innovation and sustainability.

Known for their cutting-edge LED technology and commitment to pushing the boundaries of energy-efficient lighting, X-LED is setting new standards for the industry.

I recently had the privilege to sit down with the team behind the brand to discuss their journey, breakthroughs in LED technology, and their vision for the future of lighting. From smart solutions to eco-conscious designs, here's what X-LED Technology had to say about lighting the way forward.

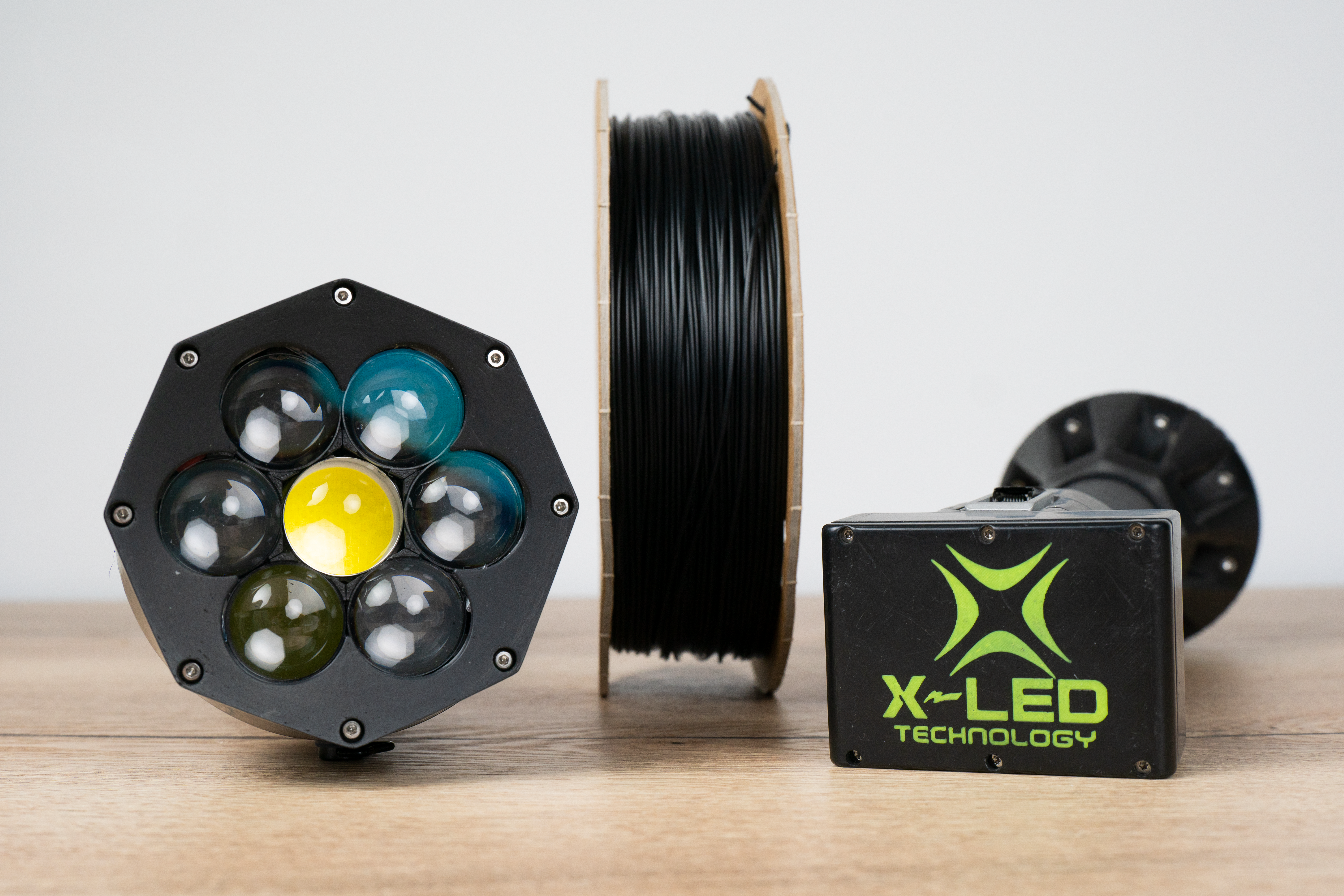

Creating a high-tech flashlight is no simple task. It involves blending expertise from various disciplines, including LED technology, lens design, electronics, and industrial design. In my journey, I collaborated with specialists across these fields to develop a product that meets rigorous standards.

The Design and Development Process

The initial design was ambitious but faced challenges due to the complexity of integrating multiple technologies. We aimed to lightweight with minimum dimensions without concessions to the sheer power output. A multifunctional flashlight, with a beam distance of 2 kilometer and floodlight option to illuminate large spaces.

All of these features had to fit in one concept. Which meant thorough testing, prototyping and adherence to strict requirements.

We conducted extensive heat measurements to ensure that the active computer controlled cooling allows the light to operate continuously, and keep internal temperatures below 55C. Even at the highest power output during hot summers.

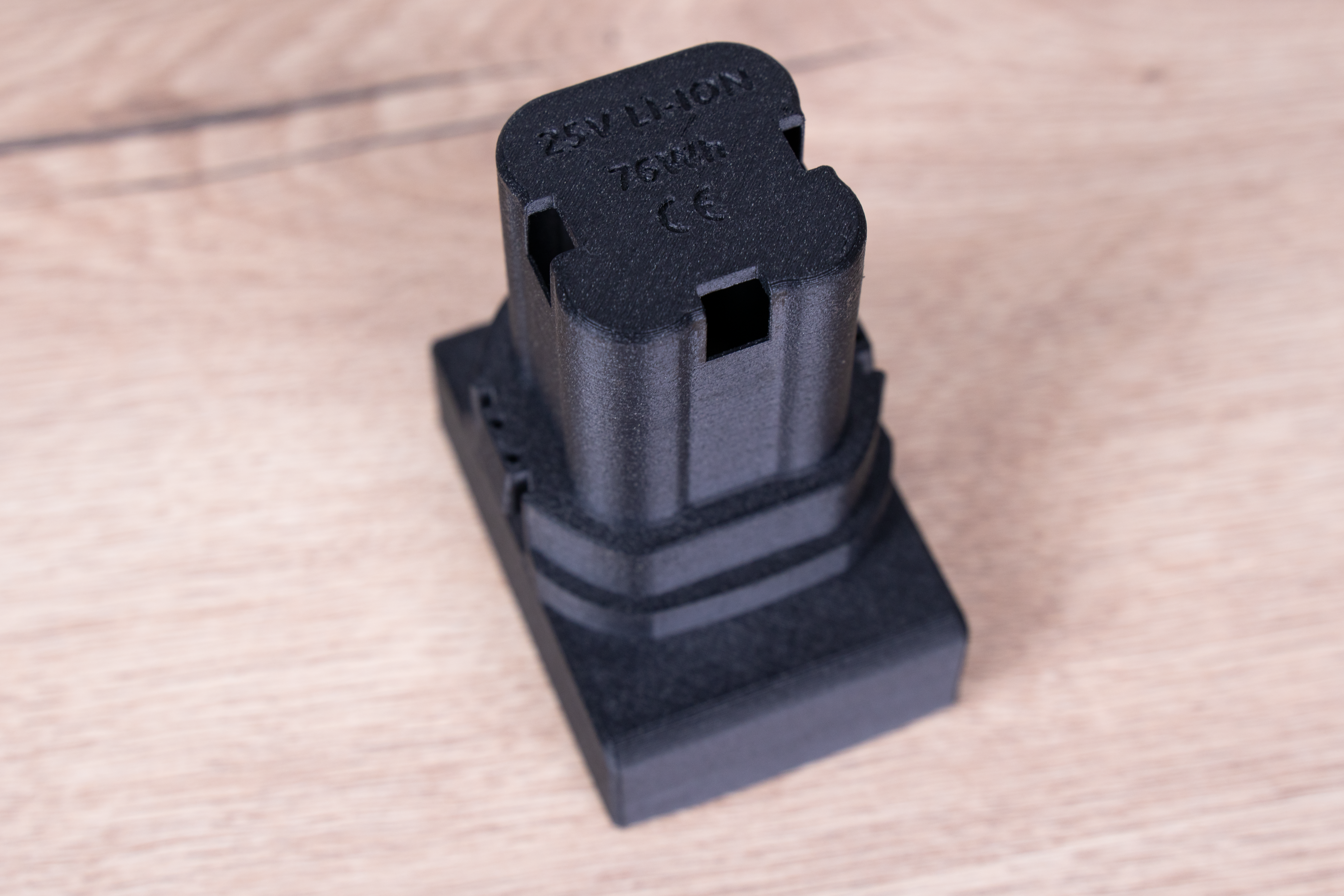

Stringent requirements for the battery technology, ensuring that the light’s quick change batteries would be both reliable and safe. This involved thorough testing for thermal performance and battery safety to prevent any risk of overheating or failure.

And important, intuitive operation with 1 On/Off and a 16 mode rotation button.

Not one button operation with complex sequences to get into program modes.

Embracing 3D Printing for Precision

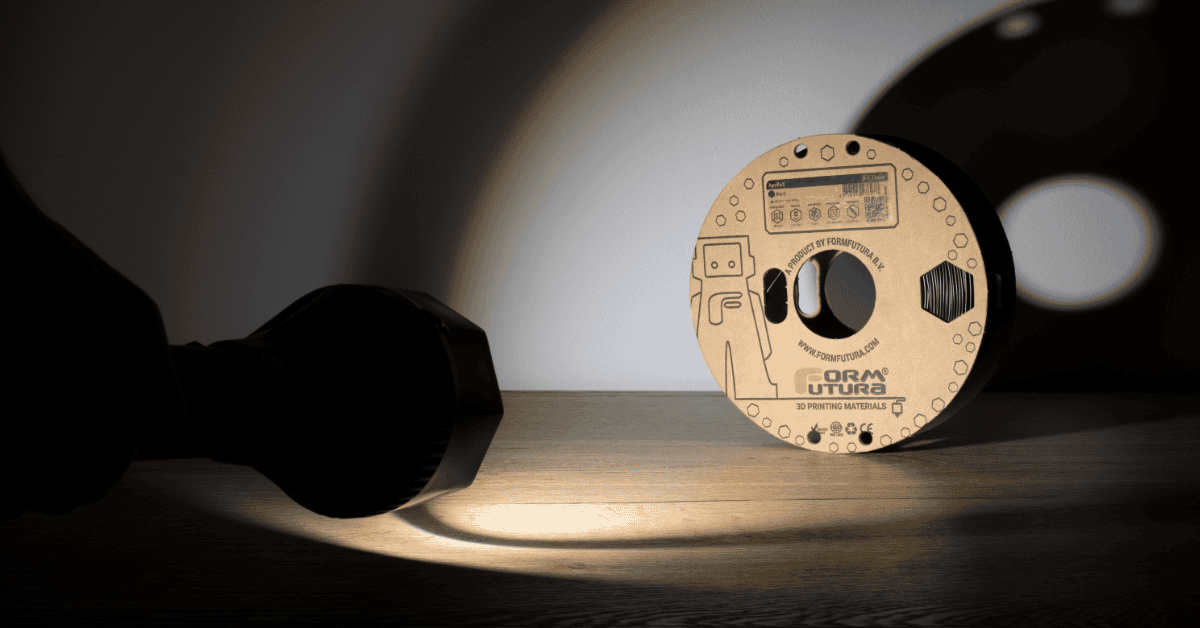

One of the key innovations in this project was the use of 3D printing. Initially, we started with a budget 3D printer for prototyping that wasn’t very reliable, but as technology advanced, we embraced multicolor 3D printers for reliable 24/7 serial production. This allowed us to quickly test and prototype designs at the same time with minimal adjustment to start serial production.

FormFutura filaments have proven to be very consistent in serial production. Every time we printed, we got the exact same copies and results, with consistent dimensions and other quality requirements.

A major advantage of serial 3D printing is that Continuous Improvement can be directly implemented.

Not being fixed to Injection molds that can’t be changed. Very simple, design change, update STEP file, prototype ok. Improvement ready for serial production.

Also major advantage, just in time, minimal stock levels 1:1 to order quantities.

Serial 3D printing with FormFutura’s 3D Printing filaments proved invaluable for creating complex components that can’t be machined, not even on the most advanced 5D CNC machines.

To produce parts of the lights housing with complex internal wire channels, which helped us achieve consistent precise fits, high strength and durability.

Material Challenges and Solutions

Selecting the right materials was crucial. We tested various filament materials, including different types of carbon fiber and Kevlar composites. Initially, other brand filaments were too weak for our needs. We found that high-quality filaments like FormFutura’s were essential for producing durable and reliable parts, 24/7. Also, the color of FormFutura was the best of all filament tested. Black is real black, not blueish, greenish.

One significant issue for consistent quality printing results was ensuring that the filaments remained moisture free. To address this, we carefully manage the storage and handling of filament to prevent moisture absorption.

Future Developments

Looking ahead, we plan to further enhance the light's water resistance. Although it currently has good protection against moisture, we aim to make it completely waterproof. This involves testing various sealing methods and coatings to ensure long-term durability, especially in challenging outdoor environments.

Additionally, we’re exploring the possibility of printing more components in-house, including chargers and battery casings. This would streamline production and allow for more customization in the future.

Conclusion

The development of this high-tech lights has been a journey of innovation and problem-solving.

From the initial design challenges to the advanced use of 3D printing and material science, every step has brought us to creating a product that is both exceptional and reliable. As we continue to refine and improve production speed and ease assembling processes, we’re excited to see how these advancements will shape the future of portable, extreme power lighting.

FormFutura being a reliable partner in the process, for 3D printing advice and exceptional quality filaments.

Feel free to check out our blog for more updates on our journey and the latest in high-tech product development!

Visit the X-LED website

Whether you're looking to enhance energy efficiency, explore the latest in lighting tech, or simply find inspiration for your next project, X-LED is a brand to watch. To learn more about their groundbreaking products and explore their full range of solutions, visit their website