Material Guide – BioFil PCL

Unlocking the Potential of PCL Filament: A Game-Changer for Medical 3D Printing

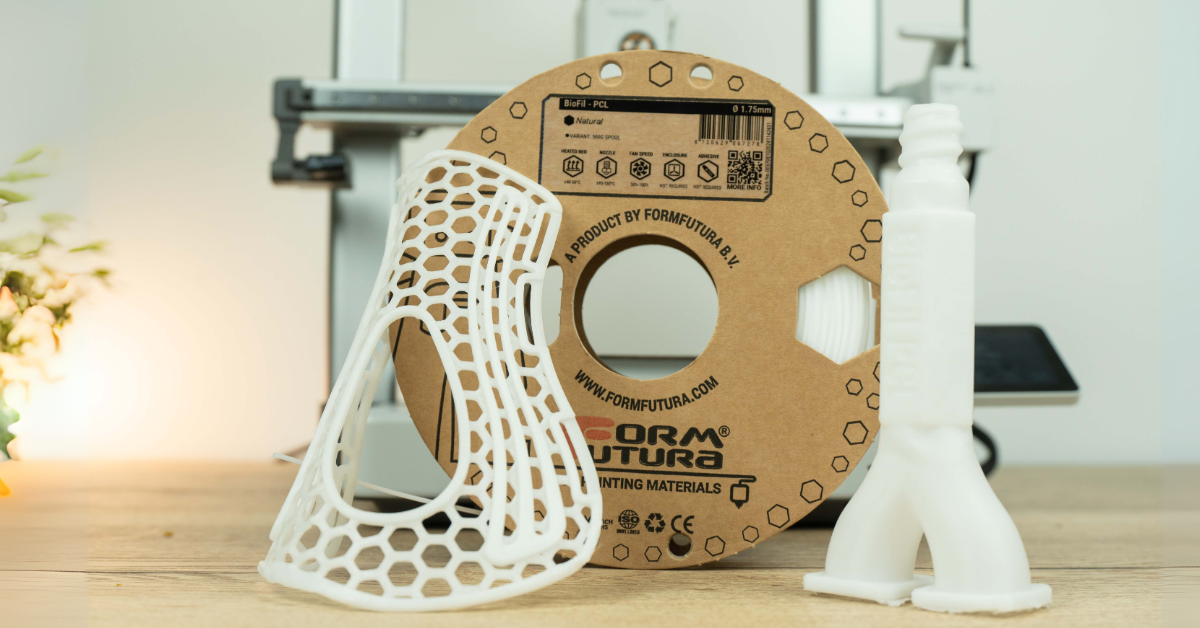

When it comes to medical-grade 3D printing, few materials offer as much versatility and innovation as polycaprolactone (PCL) filament. Among the top choices is BioFil – PCL, a high-quality, biodegradable filament ideal for orthopedic, orthotic, and biomedical applications. Its unique properties—especially its ability to be reshaped in warm water—set it apart as a revolutionary material in the medical and assistive device industries.

Why PCL? The Perfect Blend of Flexibility and Functionality

BioFil – PCL stands out for its low-temperature printing capability and exceptional mechanical properties. Unlike conventional thermoplastics, this filament allows printed parts to be reshaped at just 55°C by submerging them in warm water. This feature enables healthcare professionals and makers to fine-tune orthotic and prosthetic designs directly to a patient’s needs, ensuring a perfect fit within minutes.

Beyond its reshaping capabilities, BioFil – PCL boasts excellent adhesion to textiles, unlocking new possibilities in the development of custom orthopedic solutions. Imagine seamlessly bonding 3D-printed insoles, midsoles, braces, or shoe components to soft, breathable fabrics—enhancing comfort and functionality for patients.

Key Features of BioFil – PCL

Reshape printed parts in warm water at 55°C

Excellent adhesion to textiles for seamless orthopedic applications

Good mechanical properties for durable and flexible prints

Compliant with EN13432 compostability standards

Biodegradable in soil, water, and home composting

Eco-friendly alternative with no toxic residues or microplastics

Real-World Performance: User Reviews & Testing

The 3D printing community has started to embrace PCL, though documentation remains limited. One user on the Printables forum shared their experience:

"I initially thought PCL was difficult to print, but I was wrong! It’s incredibly easy to work with, producing smooth, polished parts that are both soft and strong. The material sticks well to the bed and even allows waste pieces to be reshaped in hot water for reuse."

We conducted our own tests to assess BioFil – PCL’s reshaping behavior at different temperatures, we put each print in hot water for 10 seconds:

50°C: No visible effect

55°C: Slight deformation on thinner parts (1.5 mm), no effect on thicker parts

60°C: Noticeable reshaping on thinner parts, minimal effect on thicker sections

65°C+: Significant deformation; at 70°C, parts lose their original shape entirely

These findings confirm that 60°C is optimal for reshaping thinner parts, while thicker components may require up to 70°C. However, exceeding 65°C risks overheating, which can cause excessive softening and loss of structural integrity.

General printing guidelines *

| Nozzle size: ≥ 0.4mm | Layer height: ≥ 0.10mm | Enclosure needed: No |

| Print temp: ± 95 – 130° C | Fan speed: 10 – 50% | Heat bed: ± 40 – 50° C |

*) Above displayed settings are meant as guidance to find your optimal print settings. These ranges in settings should work for most printers, but please do feel free to experiment outside these parameters if you think it is suitable for your printer. There are a lot of different type of printers, hot-ends and printer offset that it is extremely difficult to give an overall one-size-fits-all setting.

Applications: Where PCL Excels

Thanks to its unique properties, BioFil – PCL is ideal for:

3D printing orthotics and soft braces

Corrective braces for medical use

Insoles and midsoles with custom flexibility

Prosthetic components with tailored fit and comfort

The Future of Medical 3D Printing

The ability to reshape and reuse BioFil – PCL makes it a sustainable and cost-effective option for medical 3D printing. Its biodegradability and non-toxic composition make it an eco-conscious choice, aligning with the growing demand for sustainable materials in healthcare.

As adoption grows, PCL filament is poised to become a staple in the medical, orthotic, and prosthetic industries. Whether you’re a researcher, medical professional, or maker exploring new frontiers, BioFil – PCL offers an exciting pathway to innovation.