Case Study – 3D Printing Prototypes

In today's fast-paced world of product development, prototyping plays a crucial role in testing concepts, functionality, and design aesthetics before final production. 3D printing, particularly with high-performance filaments like those from FormFutura, has revolutionized the prototyping process by making it faster, more efficient, and cost-effective. This case study explores how FormFutura filaments are used to create functional prototypes across industries, showcasing their versatility and performance.

The Role of 3D Printing in Prototyping

Traditionally, prototypes were built using processes like CNC machining or injection molding, which required significant time and costs. 3D printing eliminates these barriers, allowing for the rapid production of models directly from digital designs. Designers and engineers can iterate quickly, modify designs, and test functionality within a matter of hours.

Key benefits of 3D printing for prototyping include:

- Reduced lead times: Prototypes can be produced in-house within days, speeding up the product development cycle.

- Cost-efficiency: 3D printing reduces material waste and eliminates the need for expensive molds.

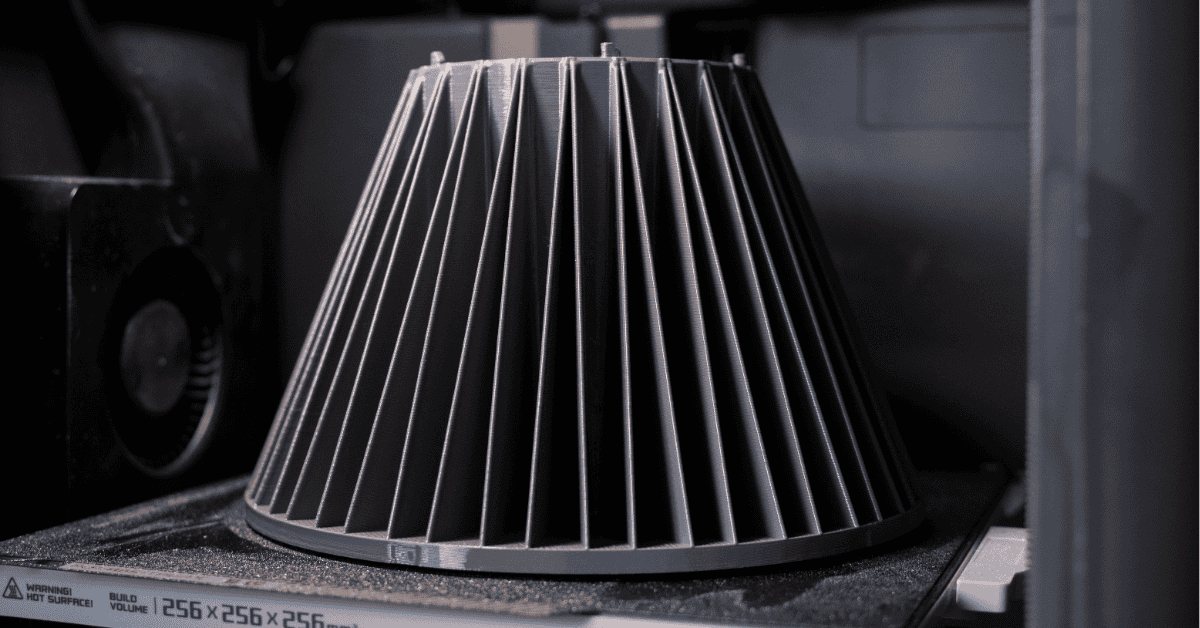

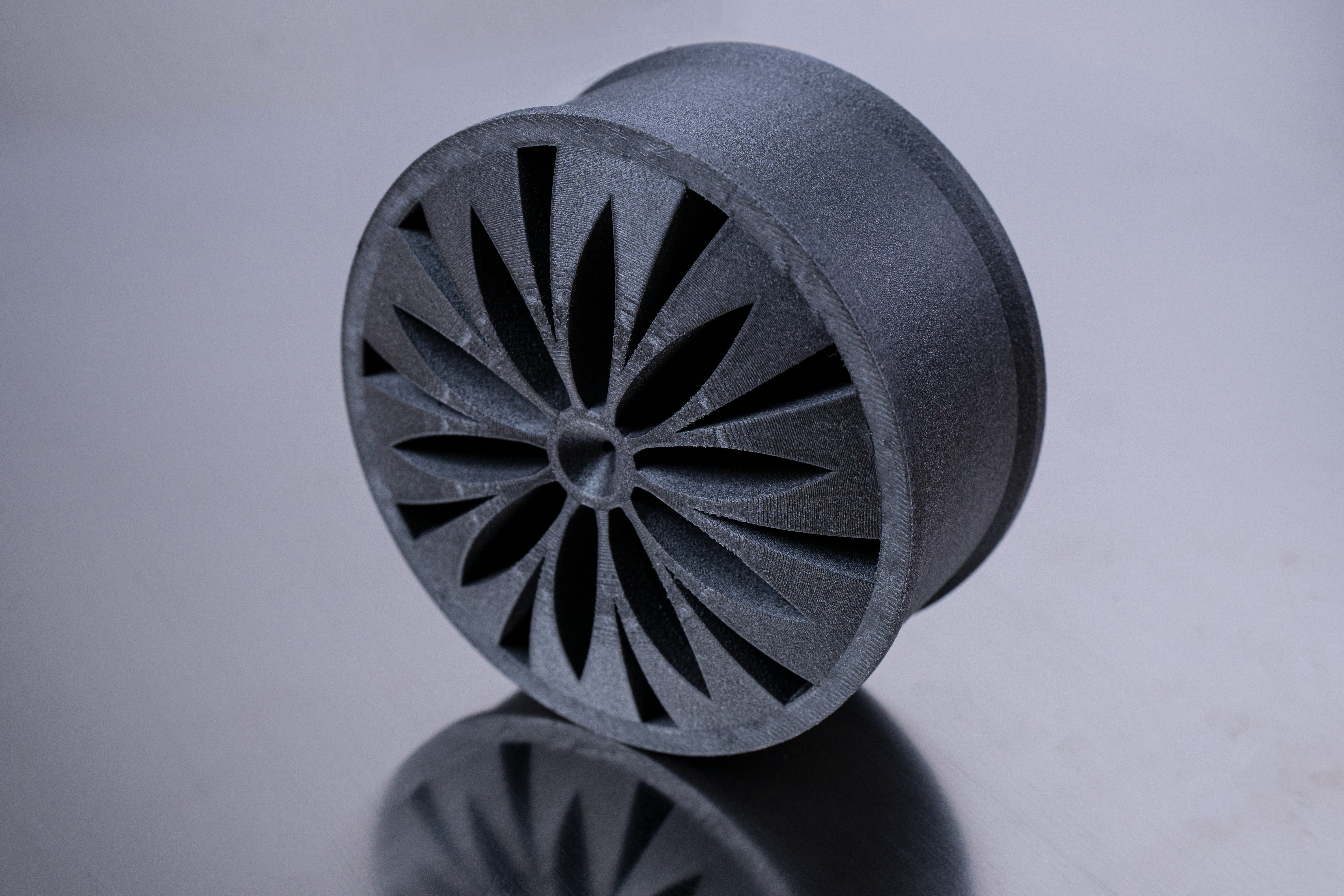

- Design flexibility: Complex geometries and intricate details can be achieved more easily with additive manufacturing.

Prototyping with FormFutura Filaments

FormFutura provides a wide range of 3D printing filaments that cater to different industries and applications. Whether you need a rigid, impact-resistant part or a flexible prototype, FormFutura filaments offer the right properties to meet your project’s requirements. Some of the standout materials include:

- ApolloX: An ASA-based filament with excellent weather resistance and UV stability. It’s perfect for creating prototypes that will be exposed to outdoor conditions.

- Volcano PLA: This high-performance PLA is engineered for strength and durability, making it ideal for functional prototypes that need to withstand mechanical stress.

- EasyFil ePLA: An affordable filament that is ideal for aesthetic prototypes or models where the design is the focus.

Case Example: Automotive Industry Prototype

A leading automotive design company needed to create a series of functional prototypes for testing the fit and performance of dashboard components. The prototypes had to be robust enough to endure mechanical stress during testing but also maintain aesthetic appeal to match the look of the final product.

For this project, the team chose FormFutura’s Volcano PLA for its balance of strength and ease of printing. With the filament’s high impact resistance and dimensional stability, the team was able to produce multiple iterations of the dashboard components within a short time frame. This allowed the engineers to test the fit, assembly, and aesthetics of the parts before committing to final tooling, saving weeks of lead time and significant costs.

Case Example: Architecture and Design Prototypes

In the field of architecture, creating physical models of buildings and structures is essential for visualizing the design before construction begins. A design firm used FormFutura’s StoneFil to print realistic architectural models that mimic the texture and appearance of real stone. This enabled the firm to present detailed, tangible representations of their concepts to clients, improving communication and collaboration during the design phase.

The ability to print high-quality prototypes helped the firm secure client approvals faster, reducing project delays.

Conclusion

FormFutura’s diverse range of 3D printing filaments makes it easier than ever to create prototypes that are functional, aesthetically appealing, and cost-efficient. Whether you’re working in automotive, architecture, or consumer product development, the right filament can streamline your prototyping process, enhance product quality, and shorten your time to market.

By incorporating high-performance materials like ApolloX, Volcano PLA, and StoneFil into your prototyping workflow, you ensure that every model is optimized for testing and validation. Explore FormFutura’s range of filaments to find the perfect material for your next prototype.