How To Print – PLA

Why 3D Print with PLA?

PLA filament is a winning combination of user-friendliness and eco-consciousness, making it a great choice for both beginners and experienced 3D printers. That in this blog how to print - PLA we go over everything you need to know to get started!

3D Printing with PLA requires lower printing temperatures than other materials, reducing energy consumption. Additionally, PLA is readily available in various colors and types, making it widely accessible for diverse projects. With its ease of use, and eco-friendly aspects, PLA is the ideal way for a smooth and sustainable 3D printing experience.

Slicer settings for PLA

Dialling in your settings for PLA printing unlocks the full potential in how to print PLA. Here's a breakdown of the key factors for each filament type:

Temperature: Aim for a printing temperature between 190°C and 230°C. Use a temperature tower to find the specific sweet spot for your filament roll. While a heated bed isn't mandatory with PLA, it's recommended for consistent performance. Set it between 50°C and 60°C, especially for larger prints, to prevent warping.

Surface Matters: Glass, PC, and PEI build plates offer good adhesion, with painter's tape improving glass bed adhesion. However, PEI shines with easy removal and strong adhesion without glue.

Speed it Up (But Not Too Much): Printing PLA within a range of 40-80 mm/s is ideal for most printers. This allows proper cooling and minimizes oozing. Standard Ender 3 printers perform best at 40-60 mm/s, while specialized printers like Voron or Bambu Lab can handle significantly higher speeds (up to 350+ mm/s).

Cooling is Key: Continuous part cooling is crucial to prevent oozing and warping. Reduce the fan speed to 50% for the first two layers to aid bed adhesion, then crank it up to 100% for the remainder of the print.

Mastering Retraction: Retraction speed and distance are key for clean prints. Aim for 50-60 mm/s speed and 0.5-1 mm distance for direct drive extruders, and 40-60 mm/s speed with 2-7 mm distance for Bowden setups. Remember, these are starting points - fine-tuning with a retraction tuning test is recommended for optimal results with your specific setup.

By understanding these settings, you can unlock the full potential of PLA and achieve smooth, high-quality 3D prints.

How to Print PLA: Tips for Consistent Success

Here are some additional practices to ensure consistent success with PLA printing:

Moisture is Your Enemy: PLA is hygroscopic, meaning it absorbs moisture from the air. This leads to under-extrusion, brittle prints, and surface bubbles. Store and use your PLA dry to avoid these issues. Utilize tools like dry boxes, dehydrators, or specialized filament dehydrators for optimal results.

Fine-Tuning is Key: Slicer settings significantly impact print quality. Experiment with temperature, cooling, and retraction settings for optimal results. Tools like temperature towers and retraction tests help with calibration.

Embrace the Heat: While not mandatory, using a heated bed improves PLA printing. It reduces warping, corner lifting, and significantly enhances bed adhesion.

Quality Matters: Invest in FormFutura's high-quality PLA filament. Cheap options often suffer from poor quality control, leading to tangled filaments, inconsistent diameter, and additional issues like contaminants and additives. Read reviews, and check technical specifications to avoid problems and achieve better printing experiences.

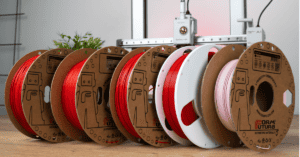

ReFill PLA

FormFutura tackles waste in 3D printing with the ReFill 2.0 system. This innovative approach replaces spooled filament with coils on cardboard cores, secured by reusable flanges. You can even 3D print your own flanges! The ReFill system boasts a massive 80% reduction in packaging waste and cuts shipping volume by up to 55%, all while offering easy switching between filament colors and materials.

Recycle Program

As one of the few biodegradable 3D printing materials, PLA stands out for its sustainability. However, it's important to remember that the process might be slow, and responsible users should consider recycling their PLA prints whenever possible.

For more information about the FormFutura recycling program, click the button below

By following these tips, you can ensure consistent success with PLA printing and unlock its full potential for creating high-quality 3D objects.

Recommended PLA

Related Article

The Best PLA Compared!

- Posted by Remy