Interview with Artus3D

Revolutionizing Orthopedic Solutions through 3D Printing with FormFutura Materials

In the ever-evolving landscape of healthcare technology, Artus3D stands out as a pioneer in leveraging 3D printing to enhance the design and production of custom orthopedic devices. With a focus on innovation, speed, and sustainability, Artus3D has been instrumental in transforming traditional processes into efficient, digital workflows.

A Journey of Digital Transformation

Lars, technical manager at Artus3D, shares how the company began as a project within an orthopedic center in Rotterdam. Initially tasked with creating custom hand braces, the team quickly realized that manual processes—such as molding with plaster—were both time-consuming and labor-intensive.

"We used to hand-craft items like braces and prosthetic covers, which involved time-consuming molding and shaping," Lars recalls. By integrating 3D scanning and printing technologies, Artus3D was able to streamline the production process and enhance the precision of their devices.

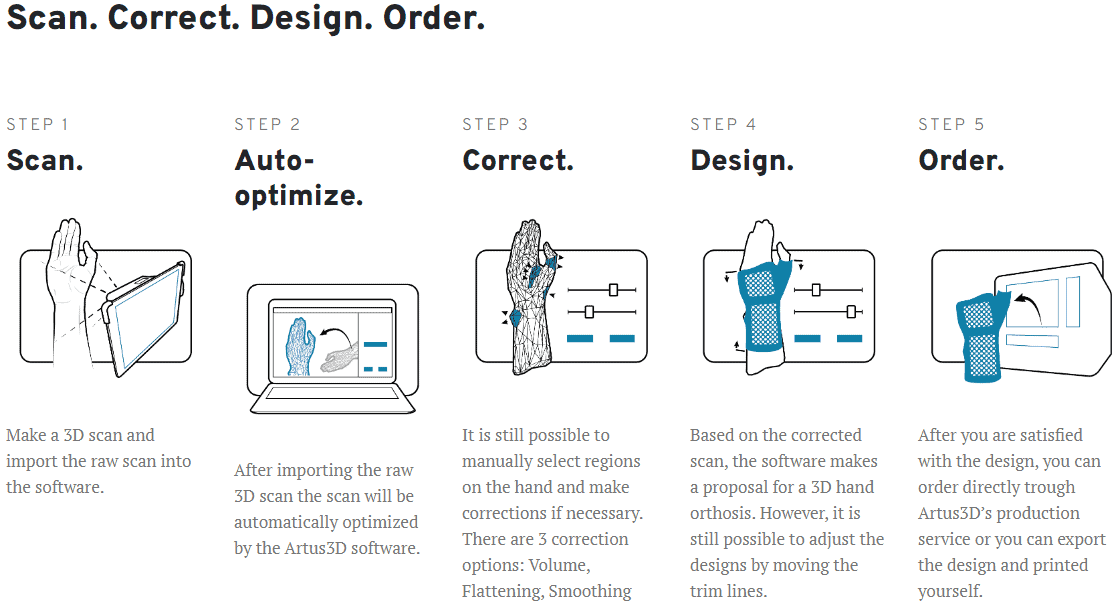

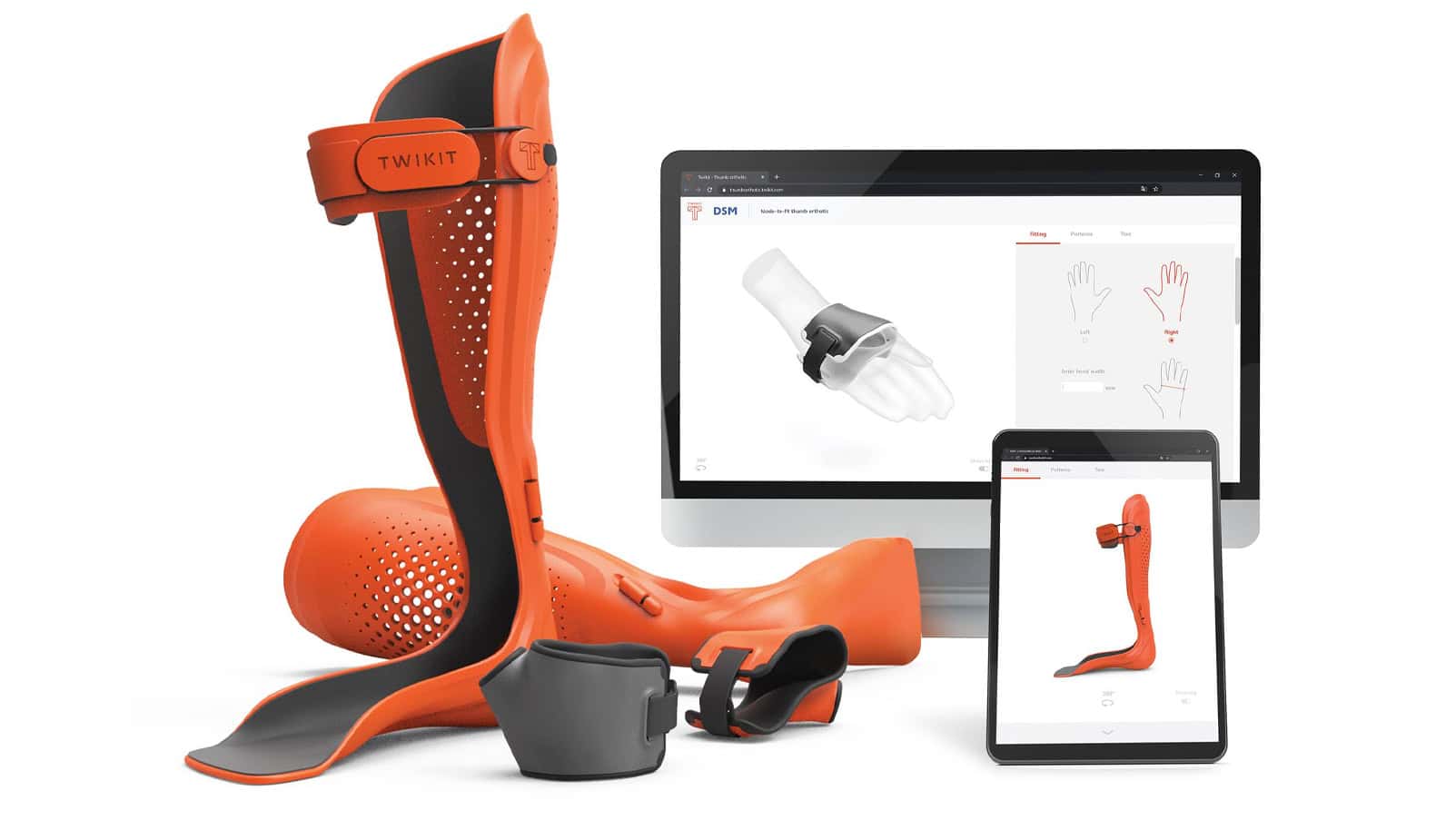

One of the cornerstones of Artus3D’s success is its proprietary software, which allows healthcare professionals to design custom-fit prosthetic covers and orthopedic devices with unparalleled accuracy. This technology has become a game-changer, enabling rapid prototyping and reducing the production time from days to hours.

Prosthetic Covers: A Breakthrough in Customization

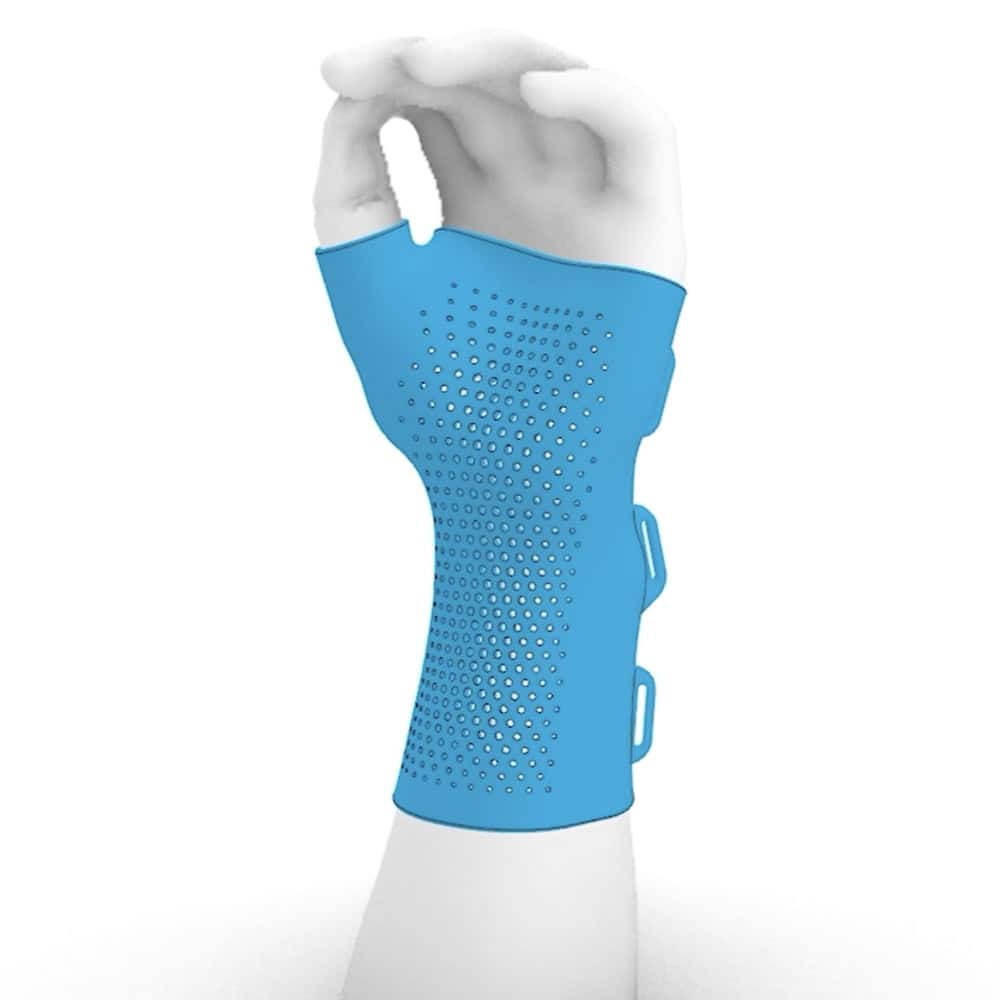

Among their standout innovations, Artus3D has revolutionized the production of prosthetic covers. Traditionally made from foam and requiring hours of manual labor, these covers are now 3D-printed using TPU filaments. The result is a durable, lightweight, and customizable solution for prosthetic users.

"Partnering with FormFutura has been key to this innovation," Lars explains. "We needed materials that not only offered durability but could also be customized for aesthetics, including skin-tone matching." FormFutura’s range of TPU filaments known for their flexibility and strength met these needs perfectly.

FormFutura Materials at the Core of Innovation

Artus3D's partnership with FormFutura plays a central role in their material selection process. FormFutura is renowned for providing high-quality, sustainable filaments designed for professional applications. The TPU filaments used by Artus3D provide not only flexibility and durability but also the possibility to match various skin tones, a critical requirement in prosthetic covers. By using FormFutura's materials, Artus3D ensures that their products are lightweight, durable, and easy to maintain.

In addition to TPU, Artus3D is exploring other advanced materials from FormFutura’s lineup, including carbon-reinforced filaments and eco-friendly options like ReForm rPET. These materials offer strength, printability, and the potential for large-format printing, all crucial for custom prosthetic solutions.

The Road Ahead: New Challenges and Opportunities

As Lars reflects on the future of 3D printing in orthopedics, he highlights the growing demand for more personalized and faster solutions. “We’re constantly pushing the boundaries of what’s possible with 3D printing,” he says. “The next step for us is to refine our software further and explore larger-scale projects that could revolutionize other aspects of orthopedics.”

For now, Artus3D remains focused on perfecting their prosthetic covers and helping other companies in the sector leverage 3D printing for their own innovations.

Artus3D

Visit the Artus3D website

Whether you're seeking cutting-edge 3D printing solutions, exploring innovative materials, or looking for inspiration for your next project, Artus3D is a brand worth exploring.