K1 Prosthetic Hand (ApolloX™) – Blogpost Part 1

We, at Formfutura, have always been firm supporters of the idea that 3Dprinting should not only be used for making beautiful objects like vases, toys and memorabilia or prototypes using our industrial filaments. We believe that 3dprinting is and will continue to be a major step forward in relieving the needs experienced by the ones that are not so fortunate in life. 3dprinting your own prosthetic parts from the comfort of your home for a fraction of the cost is one of the pillars that drives and will keep on driving the 3dprinting movement.

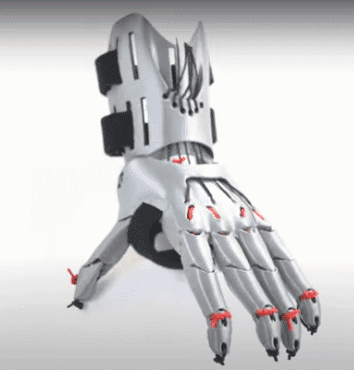

To underline that statement we started looking at what we could realise using our filaments. We soon found the fantastic organisation called “Enabling The Future”, who are doing just that. 3dprinting of a line of prosthetic hands made specially (but not only) for children. We started analysing the designs but soon realised that hands were all very mechanical looking and driven by the phrase “function over form” which off course is totally ok as a prosthetic hand that looks really nice but does not provide any functionality is useless. But then we found the K1 hand. A beautiful anthropomorphic hand that fitted every criteria we wanted to fulfil.

During our research into the hand we noticed the lack of build logs, manuals or videos of working examples. After our first attempts to print it we soon found out why. It is one tough object to print where one must address a number of difficulties and look at the datasheets in search of a material that fits just right. Here is the detailed journey we undertook to build this beautiful hand including the parts that need extra attention and the corresponding print settings in Simplify3D.

We hope that this first blogpost will help others in successfully printing this fantastically designed prosthetic hand and provide some comfort to those who need it.

The K1 hand by Evan Kuester

Download the K1 hand .stl files here

The beginning

We started off with an analysis of the components that make up the K1:

We have 3 identical fingers, 1 pinky finger, a thumb, the palm and a forearm piece. The whole will be put together without any metal objects. Instead the design makes use of printed plugs that snap into position where the joints are. We have 5 plugs for the fingers and 2 larger plugs that form the wrist joint and connect the hand to the forearm piece.

The hand is closed by moving the wrist. That movement will cause tension on the clear PPMA strands we are using and the hand closes. Move the wrist back, the tension will be relieved and the elastic bands will pull the hand back open. Not a very complex design but as always the devil is in the details.

We started out using our ApolloX™ filament. We selected our ApolloX™ due to the fact that it’s a very sturdy material (outdoor and automotive grade), UV resistant and weather resistant, has great flow when printing and comes with zero-warping technology. We thought that this polymer would provide enough stiffness and aesthetic value to complete the hand in one go. But as we as printer enthusiast all know, it’s a journey.

The complex choreography of print settings, printer setup and capability, material knowledge, 3D design and hands-on experience needed to produce top-notch prints is a tough nut to crack and while the ApolloX™ provided beautiful results, the plastic itself was just not strong enough to endure during our testing phase as we put the hand through some major stress to make sure it’s as functional and lasting as it should be.

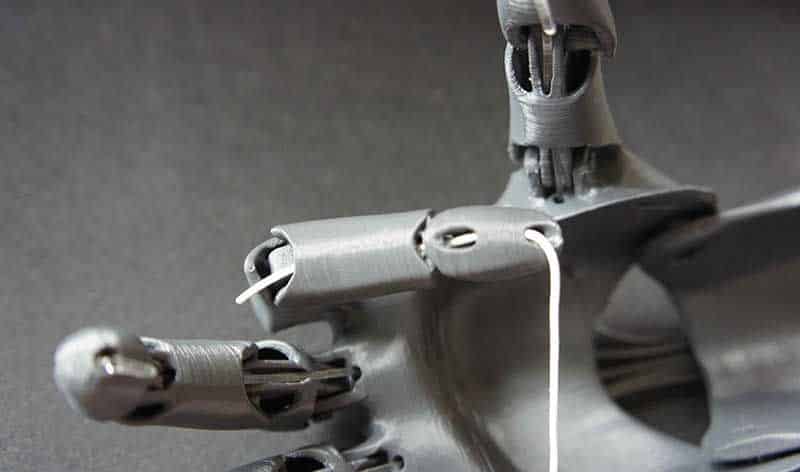

To be more precise, the joint walls are very thin to provide for a great aesthetic look. But even with 100% infill they would snap when picking up heavy items or making extreme and fast movements. Luckily we have about 20 materials in our filament portfolio and so we dove into the datasheets to find a material that would provide even more strength : our industrial-grade ABS-based engineering filament called TitanX™.

Here are some shots from printing the K1 with the ApolloX™ and the print settings we used in S3D to get to this stage (these are all untreated parts that came straight off our Lulzbot Taz-5 printer):

We were very happy with the print quality and the ability of the filament to reproduce even the finest details. Even the hard parts where we had to add support structures inside some joints (the fingers have joints that print-in-place) came out perfect and removing them was a piece of cake.

The palm needed heavy support structures as it stands on the printer bed only on a few small pieces (especially when printing the hand above 50% infill) and would start rocking back and forth. But the end piece was perfect in appearance and the force needed to close the hand was minimal. It looked and felt (when giving someone a handshake) like a human hand and not like robot or terminator hand so from our perspective this prototype was a success.

In our next post we continue our journey and create the hand using our industrial-grade ABS-based engineering filament called TitanX™ to make sure the hand not only looks and feels great but provides a real functional augmentation for those that need it!

Thanks for reading and if you have any questions please feel free to write us a comment below!