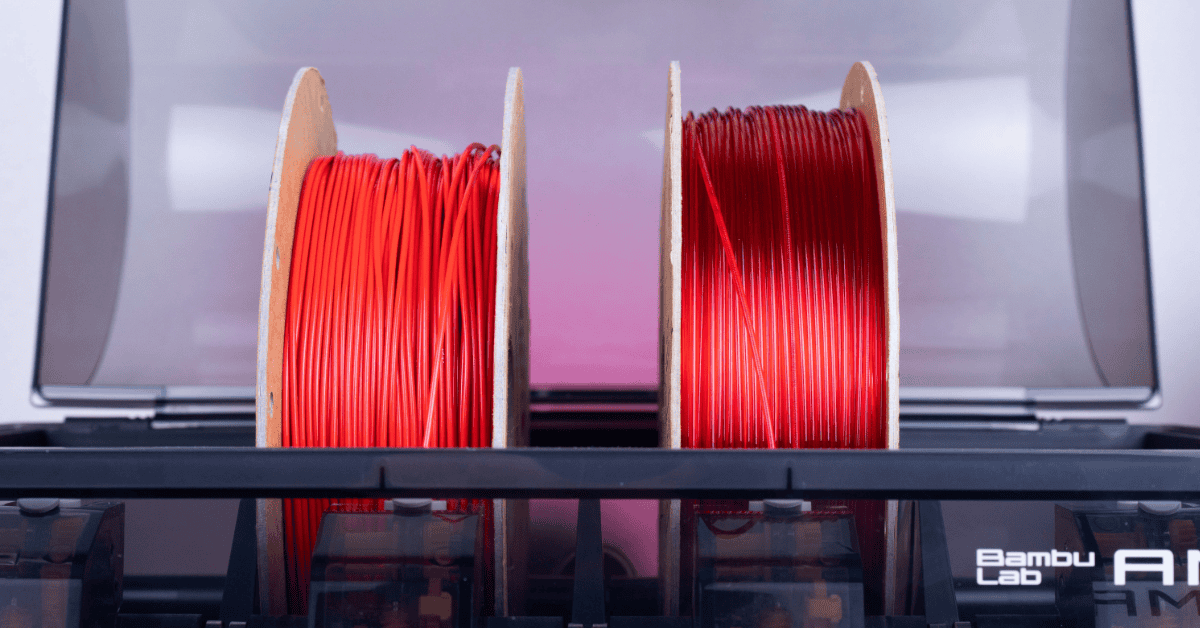

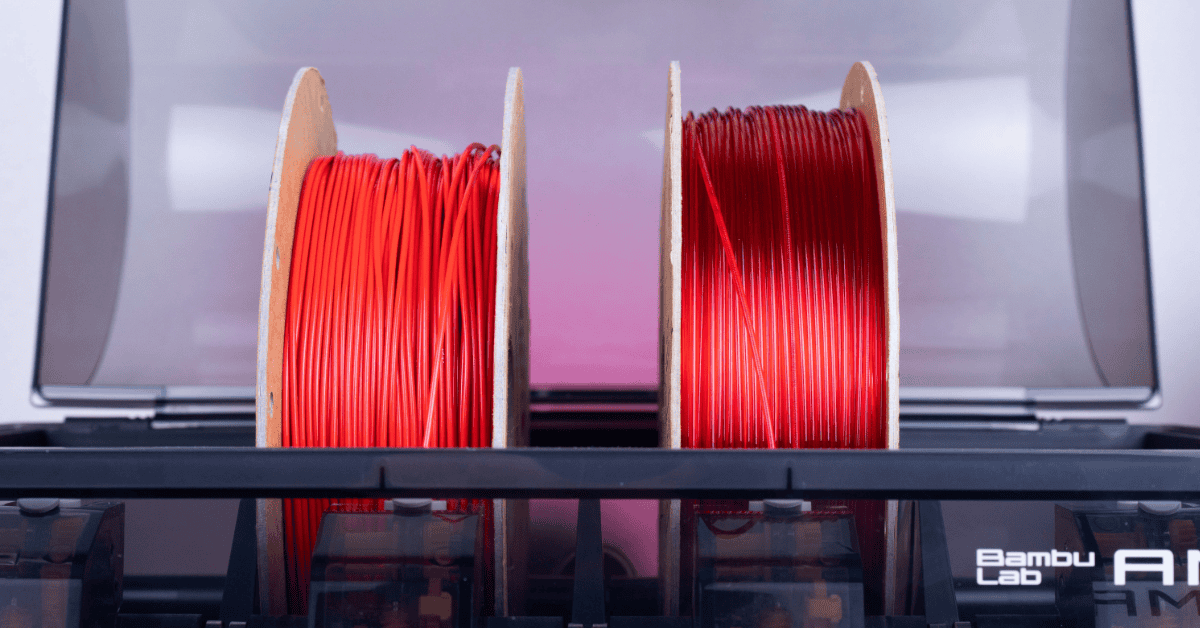

Material Guide – PETG

PETG (Polyethylene Terephthalate Glycol) is rapidly becoming a favorite material in the 3D printing world. It combines the best qualities of PLA and ABS—offering exceptional strength, durability, and temperature resistance without compromising on flexibility.

Its chemical resistance, transparency, and ease of printing make it an excellent choice for both hobbyists and professionals. If you're crafting intricate designs or functional prototypes, PETG delivers superior performance while remaining easy to work with.

In this blog we highlight, what PETG filament is, Suitable Applications, advantages over other Filaments like PLA and ABS and how to successful 3D print with PETG!

What is PETG Filament

PETG (Polyethylene Terephthalate Glycol) is a versatile filament known for its durability and ease of printing. It combines the best features of both PLA and ABS, offering the flexibility and impact resistance of ABS with the ease of use of PLA.

PETG is also chemically resistant, water-repellent, and temperature-resistant, making it ideal for producing strong, functional parts. Its transparency and glossy finish add aesthetic value, making it popular for both industrial applications and hobbyist projects. PETG also produces very limited unpleasant odors during printing and is 100% recyclable.

Why PETG is Ideal for Various Applications

PETG’s combination of durability, chemical resistance, flexibility, and transparency makes it perfect for a variety of applications. Its low shrinkage, excellent layer adhesion, and resistance to impact allow it to perform well under demanding conditions, making it the material of choice for functional and aesthetic purposes alike.

1. Medical Devices

PETG’s chemical resistance and biocompatibility make it ideal for producing durable, sterilizable medical equipment like face shields and diagnostic tools.

2. Food Packaging

PETG is FDA-approved for food contact, making it perfect for creating food storage containers and beverage bottles due to its non-toxicity and moisture resistance.

3. Prototyping

Its durability and easy post-processing enable the creation of high-strength prototypes for engineering and product development.

These qualities make PETG an excellent choice for projects requiring both durability and aesthetic appeal.

Printing with PETG

PETG is user-friendly but requires specific settings for optimal results. Start with a print temperature between 230°C and 250°C to ensure smooth extrusion, as PETG becomes more fluid at higher temperatures. A heated bed set to 70°C–90°C helps prevent warping, while cooling fans aid in achieving a glossy finish. PETG adheres well to most surfaces, but using glue stick or painter's tape can enhance bed adhesion. Be mindful of stringing by adjusting retraction settings. PETG’s low warping and excellent layer bonding make it suitable for high-speed printing.

PETG Print Settings*

Nozzle Size: ≥ 0.1 mm

Bed Temperature: ± 70 – 90° C

Print speed: Medium / High

Nozzle Tempeature: ± 230 – 260° C

Filament Drying: Required**

First Layer Cooling: No

Layer Cooling: 20-50%

Enclosure: Optional

*These are general guidelines, for specific print settings, please refer to the product page.

**Don't skip the drying step! PETG is prone to absorbing moisture from the air, which can lead to printing problems like bubbles and weak layers. To ensure successful prints, thoroughly dry your PETG filament for at least 24 hours at 50°C (122°F) before printing. You can even keep the filament drying while printing for optimal results.

Advantages over other filament

PETG offers several notable advantages over PLA and ABS. Unlike PLA, which can be brittle, PETG provides a better balance of flexibility and toughness, making it ideal for functional parts that need to withstand stress. It also has a lower tendency to warp compared to ABS, simplifying the printing process and reducing the risk of print failures. While PLA is easy to use, PETG combines ease of printing with superior strength and durability.

In terms of chemical resistance, PETG outperforms both PLA and ABS, making it suitable for applications where exposure to chemicals is a concern. It also produces fewer fumes and less odor during printing compared to ABS, contributing to a more pleasant printing experience. Additionally, PETG’s glossy finish often results in visually appealing prints, whereas PLA typically has a matte finish and ABS requires additional post-processing for a similar appearance.

Although PETG is not as biodegradable as PLA, it is more environmentally friendly than ABS due to its recyclability and reduced environmental impact. With its combination of strength, ease of use, chemical resistance, and aesthetic quality, PETG is a versatile and practical choice for a variety of 3D printing applications.

Tips for successful PETG Printing

Keep PETG filament dry: Store your PETG filament in a dry place, preferably in a sealed bag with desiccant or silica gel, to prevent moisture absorption and air bubbles in your 3D prints.

Heated bed: If printing without a heated bed, use painter’s tape or adhesive spray to ensure good first layer adhesion. Poor adhesion can lead to cracking when the object is flexed or stretched.

Direct drive extruder: For optimal PETG printing, use a direct drive extruder that provides adequate support for the filament, preventing it from bending or being pushed in the wrong direction.

If using a Bowden extruder: Ensure the filament does not get stuck against the Bowden tube wall.

Disable or limit retraction: Disable or minimize retraction to max ± 5mm for TPU printing, as excessive retraction can cause filament jams.

Printer settings: Adjust printer settings specifically for the filament you’re using before printing with PETG. Use the settings from this blog and experiment what works best for your 3D printer!