Material Guide – ReFill PLA

Star of the Show

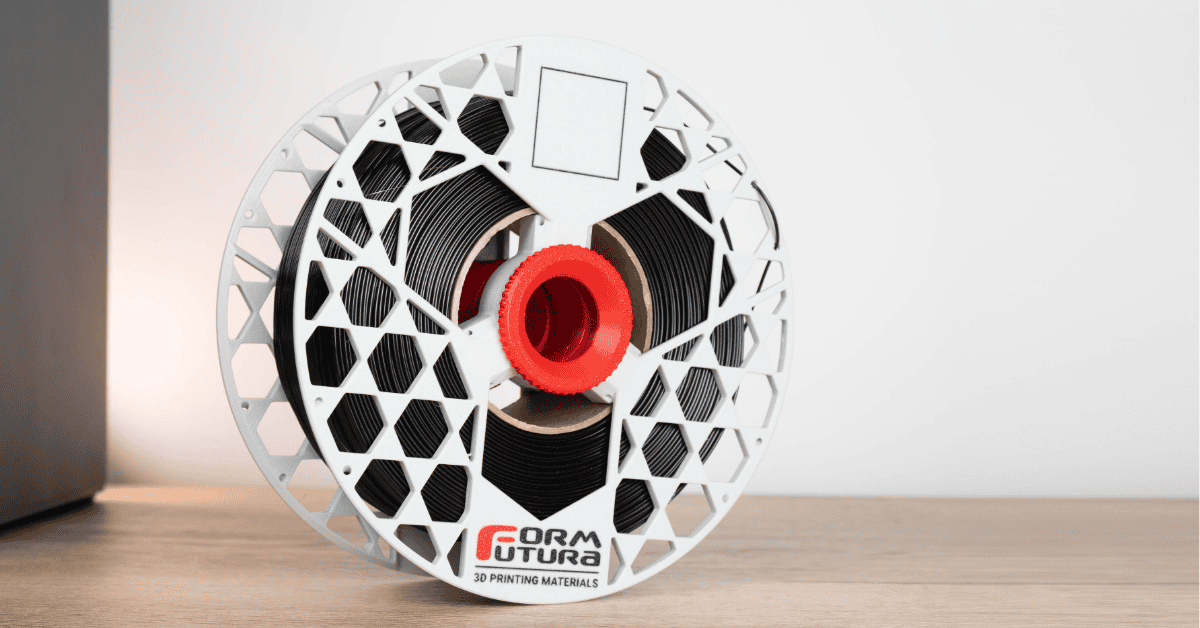

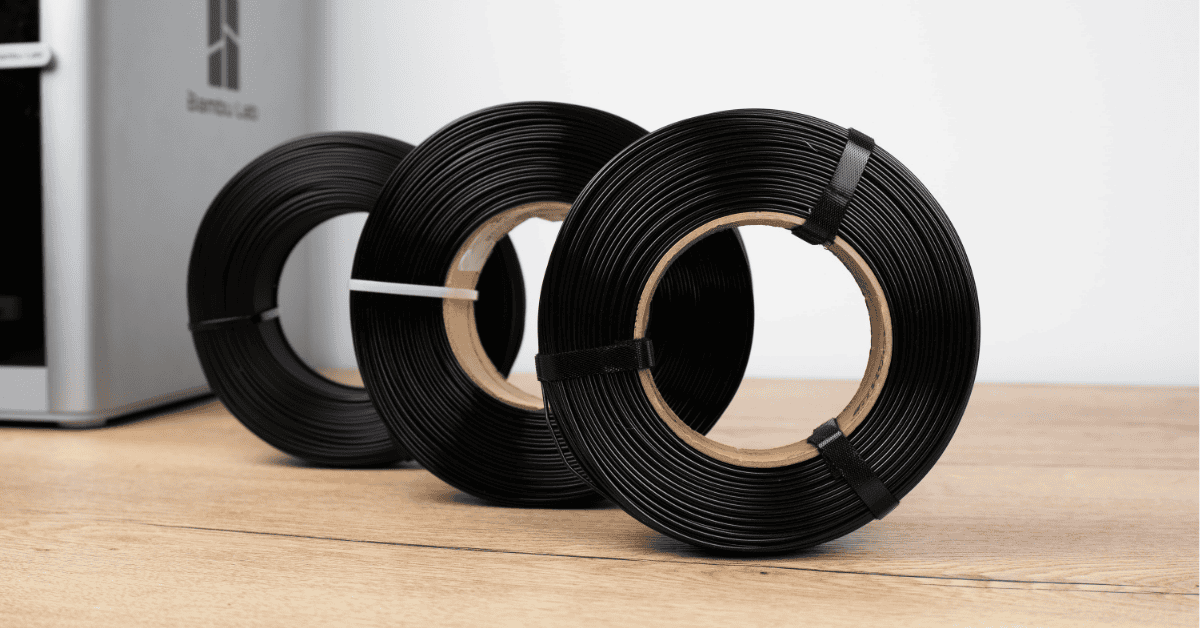

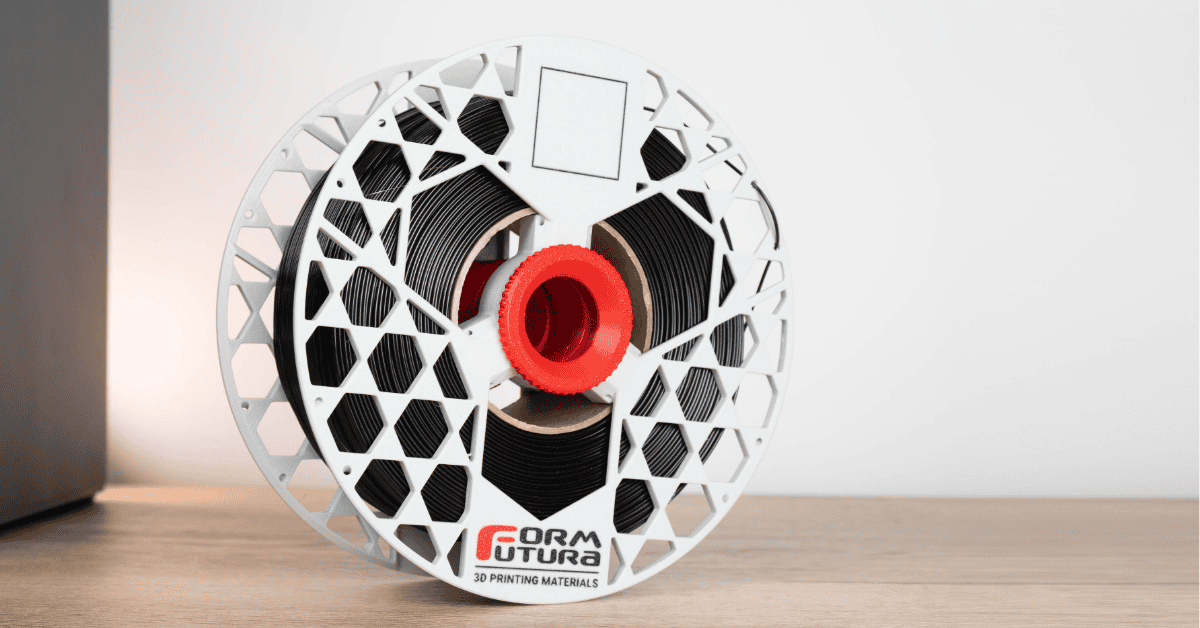

ReFill offers a completely new way to experience 3D printing filament. We’ve ditched the plastic, and cardboard spools altogether. ReFill consists only of the filament coil itself, housed in a reusable, vacuum-sealed bag. This significantly reduces waste compared to traditional spools.

FormFutura’s ReFill system is designed with the aim of lessening your carbon footprint. It brings an 80% reduction in packaging waste, while potentially decreasing shipping volume by up to 55%.

The user-friendly system is compatible with nearly all FDM printers, including the widely used AMS system.

Characteristics

Minimal packaging waste (no spool / box): This filament is designed with environmental considerations in mind, reducing packaging waste by eliminating the need for spools or boxes.

Retail price of €15,- for 0.75kg coils: The filament is affordably priced at €15 for a 0.75kg coil, offering a cost-effective option for 3D printing enthusiasts and professionals alike.

Food contact approved according to EU directives: The filament complies with EU directives for food contact, ensuring it is safe for applications involving direct contact with food.

Available in a wide range of colors: Customers can choose from a diverse selection of colors, making it easy to find the perfect match for any project.

Available in 0.75kg coils and 2kg coils: The filament is offered in two convenient sizes—0.75kg and 2kg coils—to suit different project needs.

Very easy to 3D print: This filament is user-friendly and easy to print, ensuring a smooth and hassle-free 3D printing experience.

How To Print With ReFill PLA

ReFill PLA Print Settings

Nozzle size: ≥ 0.15mm

Layer height: ≥ 0.1mm

Flow rate: ± 100%

Print temp: ± 200 – 230° C

Print speed: Medium

Retraction: Yes ± 5mm

Heat bed: ± 50 – 60° C

Fan speed: 50-100%

Experience level: Beginner

Tips for printing ReFill PLA

Keep PLA filament dry: Store your ReFill PLA filament in the reusable sealed bag it comes in. As an extra, put some desiccant, like silica gel, in the bag to prevent moisture absorption and air bubbles in your 3D prints.

Heated bed: If printing without a heated bed, use painter’s tape or adhesive spray to ensure good first layer adhesion. Poor adhesion can lead to cracking when the object is bend.

Direct drive extruder: For optimal PLA printing, use a direct drive extruder that provides adequate support for the filament, preventing it from bending or being pushed in the wrong direction.

If using a Bowden extruder: Ensure the filament does not get stuck against the Bowden tube wall. Make sure you are printing with the correct diameter!

Printer settings: Adjust printer settings specifically before printing with ReFill PLA. Use the settings from this blog and experiment what works best for your 3D printer!