Mission Sustainability 2025

Mission Sustainability 2025: A Greener 3D Printing Future with FormFutura

Introduction

The urgency of environmental conservation has never been greater. As the 3D printing industry grows, so does the responsibility to minimize its ecological footprint. At FormFutura, we recognize this challenge and are committed to creating sustainable solutions. Mission Sustainability 2025 is our pledge to lead the additive manufacturing industry toward a more eco-friendly future.

Despite being seen as a double-edged sword, 3D printing inherently offers a more environmentally friendly production method. It allows for the precise consumption of necessary resources, and the development of sustainable materials is a promising avenue.

As additive manufacturing (AM) relies heavily on technology, its flexibility and adaptability present opportunities for future growth in sustainability. The potential benefits include waste reduction, lower energy consumption, cost savings, and the creation of more sustainable products.

In this blog, we will go over the initiatives FormFutura has taken so far, and our plans for 2025.

Why Sustainability Matters

The environmental impact of 3D printing lies primarily in its reliance on plastics for filament, spools or both, and energy consumption.

However, this industry also presents an opportunity: through innovation, we can create materials and processes that reduce waste, reuse resources, and lower carbon emissions. A sustainable approach not only benefits the planet but also inspires confidence among environmentally conscious consumers and businesses.

FormFutura's Initiatives

To achieve these goals, FormFutura is dedicated to pushing the boundaries of sustainability. Over the past few years, we have launched several key programs and initiatives to achieve our goals.

In 2020, we made a pivotal decision to replace traditional plastic spools with recyclable cardboard alternatives. This shift was not just about reducing waste; it was a statement of our commitment to sustainability. Crafted from unbleached recycled materials, these sturdy cardboard spools are fully recyclable and environmentally friendly. We’re proud that our initiative has encouraged other brands to adopt similar practices, helping to establish a more sustainable standard across the industry.

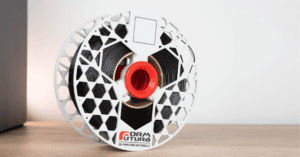

But we didn’t stop there. Our ReFill filaments, designed for use with reusable master spools, are a testament to our drive to innovate for the planet.

ReFill

ReFill PLA is manufactured for usage with re-usable master spools. By eliminating disposable spools, these filaments significantly reduce packaging waste with an 80% reduction, while potentially decreasing shipping volume by up to 55%. All while offering users a practical, eco-conscious solution.

It’s a small change with a big impact, made even better by the ability for users to 3D print their own spool components.

ReFill emphasizes waste reduction by enabling customers to reuse filament spools. FormFutura is offering two options, it's possible to find the plans for free on websites like Printables or Thingiverse, to print yourself. Alternatively, FormFutura offers the ReFill Systems already printed, and ready to use.

ReForm: Sustainable Innovation in 3D Printing

ReForm by FormFutura represents our commitment to combining sustainability with affordability. Crafted entirely from renewed and recycled materials, ReForm filaments eliminate the need for virgin fossil or natural resources, offering an eco-conscious alternative without compromising on quality.

Every detail of ReForm’s design has been optimized for sustainability. The filaments are spooled on durable, FSC-certified cardboard spools and packaged in recycled, climate-neutral cardboard boxes. This makes all FormFutura packaging 100% recyclable, reducing environmental impact at every stage.

What sets ReForm apart is its practicality. These filaments are designed to work seamlessly with standard 3D printing tools and settings—no special equipment required. And by utilizing industrial waste as a raw material, we not only reduce our environmental footprint but also bring high-end sustainable filaments to the market at unbeatable prices.

ReForm also marks a milestone as the first filament range available on industrial-sized cardboard spools, offering greater efficiency for large-scale projects while maintaining a commitment to eco-friendly practices.

Closing the Loop: The FormFutura Recycling Program

At FormFutura, we’re passionate about creating a circular future for 3D printing. Our Recycling Program offers an easy way for users to send back failed prints, leftover filament, and other materials. These returned items are transformed into high-quality recycled filaments, significantly reducing waste while giving new life to old materials.

The program embodies our commitment to resource efficiency, ensuring that every piece of material contributes to a more sustainable ecosystem. Whether you're a hobbyist or a professional, participating in this initiative not only helps the planet but also strengthens the 3D printing community’s role in driving sustainability forward.

For more information on how you can join this program, visit FormFutura Recycling Program.

Earth Day 2025: Celebrating Progress and Innovation

On Tuesday, April 22, 2025, the world will come together to celebrate the 55th anniversary of Earth Day. This global event, which unites over a billion people, is a reminder of the collective effort needed to combat issues like pollution, deforestation, and climate change. At FormFutura, Earth Day is an opportunity to reflect on our progress and recommit to creating a sustainable future for 3D printing.

This year, we’re focusing on expanding and enhancing our initiatives to make an even greater impact:

- Broader Recycling Capabilities: We aim to process an expanded range of materials, including challenging types like ABS and ASA, allowing more users to participate in our Recycling Program.

- Scaling ReFill Participation: By introducing new incentives, and materials, we hope to encourage broader adoption of our ReFill filaments and the use of master spools, reducing single-use packaging waste.

- Global Collaboration: We’re working to raise awareness about sustainable practices in 3D printing by collaborating with international communities, sharing knowledge, and inspiring innovation across the industry.

This Earth Day, we invite you and our other customers and partners to join us in celebrating the progress we’ve made together. Whether it’s through recycling materials, choosing sustainable filaments, or supporting our initiatives, every action contributes to a cleaner, greener planet. Together, we’re proving that innovation and sustainability can go hand in hand.

ReForm - Organic rPLA

ReForm Organic rPLA is the latest addition to our ReForm initiative, aimed at creating sustainable filaments by utilizing upcycled PLA materials from our production processes. This filament not only reduces plastic waste but also maintains the premium quality and performance expected from FormFutura products.

The "Organic" label is highlighting what makes this filament unique, as ReForm - Organic rPLA is 100% made from recycled PLA.

The results of this unique product is a filament with a natural, matte finish and a unique organic look and feel, perfect for environmentally conscious makers and designers.

Recommended blogs

Material Guide – ReForm – Organic rPLA

- By Remy

Material Guide – ReFill PLA

- By Remy

Material Guide – ReFill Explained

- By Remy

Is recycling the best solution for 3D printing scraps?

- By FormFutura