It is very easy to 3D print with CarbonFil CF03, it prints with great precision and superb layer adhesion. This filament does require the use of a 0.6 diameter nozzle. While the main focus of this filament is on utilizing the aesthetics of carbon. It shows great resistance to chemicals and machinability properties.

ReFill

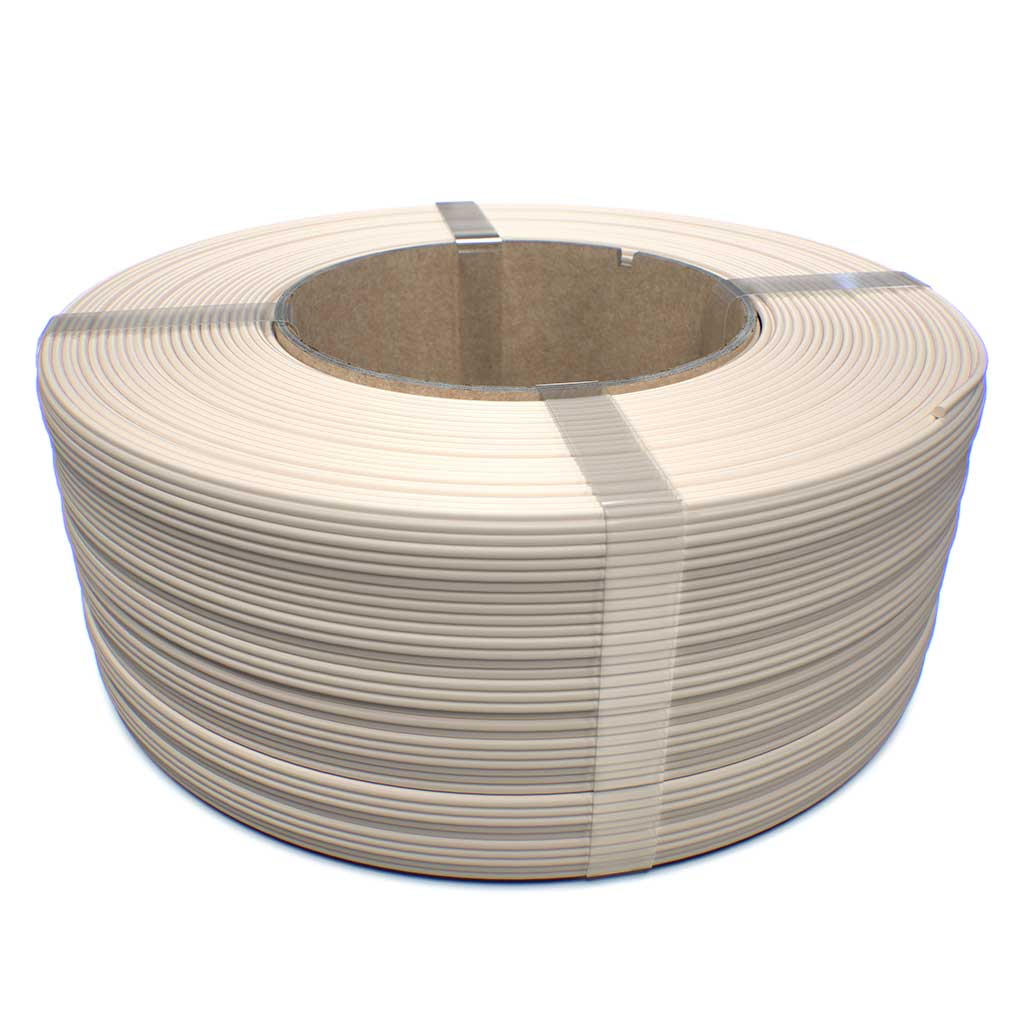

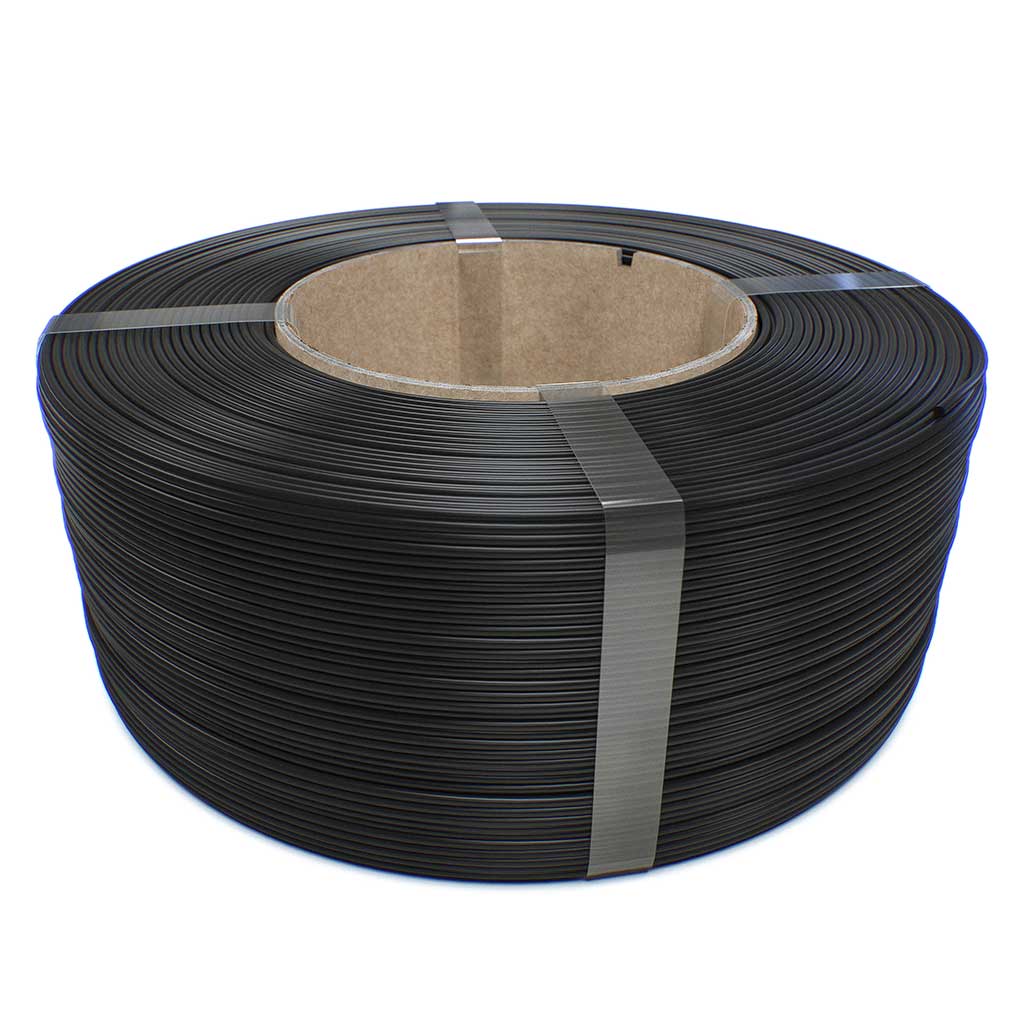

ReFill offers a completely new way to experience 3D printing filament. We’ve ditched the wasteful plastic spools altogether. ReFill consists only of the filament coil itself, housed in a reusable, vacuum-sealed bag. This significantly reduces waste compared to traditional spools.

FormFutura’s ReFill system is designed with the aim of lessening your carbon footprint. It brings an 80% reduction in packaging waste, while potentially decreasing shipping volume by up to 55%.

The user-friendly system is compatible with nearly all FDM printers, including the widely used AMS system.

Recommended product: FormFutura ReFill System

Important key features

- PETG with amazing carbon look and aesthetics

- 3D prints without visible layers

- Good chemical resistance

- Good machinability properties

- High speed printing compatible

Suitable applications

- Functional prototyping

- Visualization aids

- PETG end use parts that do not require the full strength of carbon

General printing guidelines *

| Nozzle size: ≥ 0.6mm | Layer height: ≥ 0.2mm | Flow rate: ± 100% |

| Print temp: ± 240 – 280°C | Heat bed: ± 75 – 85° C | Fan speed: 0-50% |

*) Above displayed settings are meant as guidance to find your optimal print settings. These ranges in settings should work for most printers, but please do feel free to experiment outside these ranges if you think it is suitable for your printer. There are a lot of different type of printers, hot-ends and printer offsets that it is extremely difficult to give an overall one-size-fits-all setting.

Storage and handling

Filament should be stored at room temperature in a dry and dark place with humidity below 15%. Recommended storage temperature is ca. 18-25°C (64.4 -77.0°F). Keep out of moisture, sunlight and direct heat. When stored properly, product has a shelf life of 24 months. To obtain the best parameters of the printed object, it is recommended to dry the material prior to usage and to 3D print it directly from a dry box.

Product export information

| HS Code: 39169090 | Description: Monofilament for 3D printing | Origin: European Union |

Safety Datasheet:

CarbonFil CF03

CarbonFil CF03 is PETG with circa 3% added carbon fibers. It combines PETG properties with the aesthetics of carbon. This results in 3D prints with a magnificent carbon finish and no visible layers.

- Ordered before 15h CET? Ships same business day

- Worldwide shipping with UPS & FedEx

- One-stop shop for 3D printing materials

Featured Products

CarbonFil CF03

CarbonFil CF03 is PETG with circa 3% added carbon fibers. It combines PETG properties with the aesthetics of carbon. This results in 3D prints with a magnificent carbon finish and no visible layers.

If a product is out of stock, it is usually replenished within two weeks.

- Ordered before 15h CET? Ships same business day

- Worldwide shipping with UPS & FedEx

- One-stop shop for 3D printing materials

It is very easy to 3D print with CarbonFil CF03, it prints with great precision and superb layer adhesion. This filament does require the use of a 0.6 diameter nozzle. While the main focus of this filament is on utilizing the aesthetics of carbon. It shows great resistance to chemicals and machinability properties.

ReFill

ReFill offers a completely new way to experience 3D printing filament. We’ve ditched the wasteful plastic spools altogether. ReFill consists only of the filament coil itself, housed in a reusable, vacuum-sealed bag. This significantly reduces waste compared to traditional spools.

FormFutura’s ReFill system is designed with the aim of lessening your carbon footprint. It brings an 80% reduction in packaging waste, while potentially decreasing shipping volume by up to 55%.

The user-friendly system is compatible with nearly all FDM printers, including the widely used AMS system.

Recommended product: FormFutura ReFill System

Important key features

- PETG with amazing carbon look and aesthetics

- 3D prints without visible layers

- Good chemical resistance

- Good machinability properties

- High speed printing compatible

Suitable applications

- Functional prototyping

- Visualization aids

- PETG end use parts that do not require the full strength of carbon

General printing guidelines *

| Nozzle size: ≥ 0.6mm | Layer height: ≥ 0.2mm | Flow rate: ± 100% |

| Print temp: ± 240 – 280°C | Heat bed: ± 75 – 85° C | Fan speed: 0-50% |

*) Above displayed settings are meant as guidance to find your optimal print settings. These ranges in settings should work for most printers, but please do feel free to experiment outside these ranges if you think it is suitable for your printer. There are a lot of different type of printers, hot-ends and printer offsets that it is extremely difficult to give an overall one-size-fits-all setting.

Storage and handling

Filament should be stored at room temperature in a dry and dark place with humidity below 15%. Recommended storage temperature is ca. 18-25°C (64.4 -77.0°F). Keep out of moisture, sunlight and direct heat. When stored properly, product has a shelf life of 24 months. To obtain the best parameters of the printed object, it is recommended to dry the material prior to usage and to 3D print it directly from a dry box.

Product export information

| HS Code: 39169090 | Description: Monofilament for 3D printing | Origin: European Union |

Safety Datasheet: