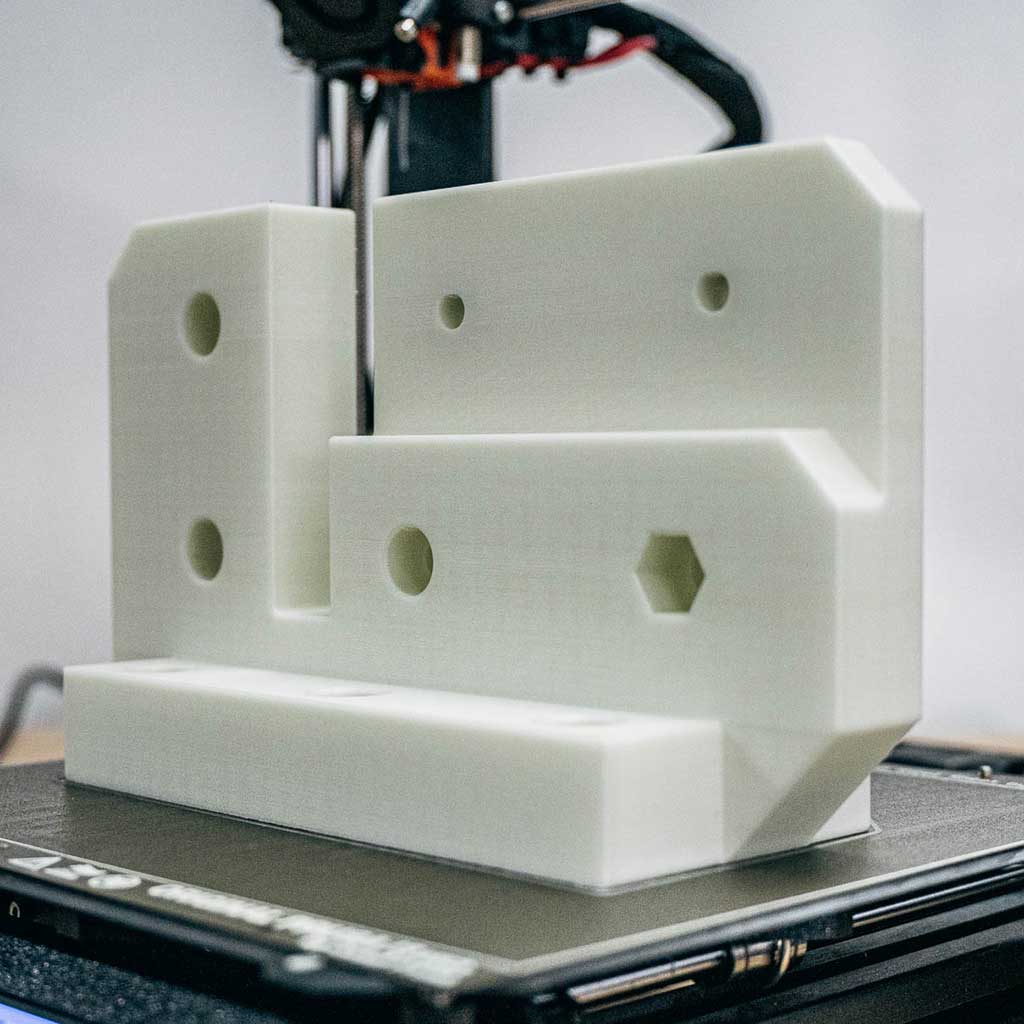

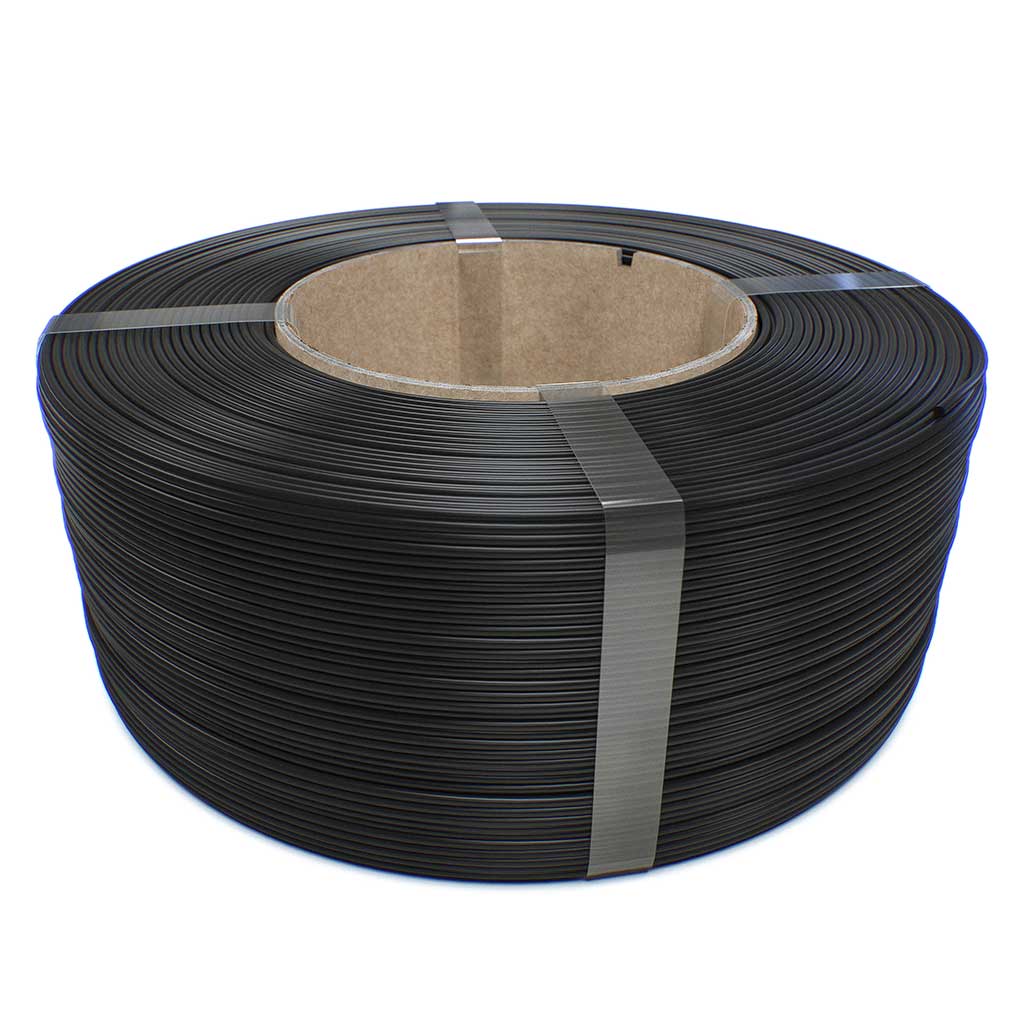

STYX PA6-CGF is a high-performance glass fiber-reinforced PA6 filament. The added glass fibers make this filament strong and stiff, without being brittle. This engineering filament is very easy to 3D print on open desktop machines. No enclosure, or heated chamber is needed. Its low shrinkage factor and perfect layer adhesion make STYX PA6-GF30 a breeze to print with.

Important key features

- Reinforced with 30% glass fibers

- High compressive strength

- Heat resistant up to 180°C

- High wear, tear, and abrasion resistance

- Excellent chemical resistance

- Easy to print on open desktop 3D printers</>

Suitable applications

- Automotive parts

- Connectors and switches

- Housings for electronic devices

- Gear wheels, bearings, and sliding elements

- 3D printing machinery parts

- Dynamically stressed parts

Glass fiber reinforcement explained

Reinforcing filaments with glass fibers results in great benefits. It combines the unique properties of both materials. The properties of the thermoplastic improve with everything glass fibers offer. Glass fibers offer lots of benefits, such as:

- Increasing stiffness

- Increasing strength

- Increasing dimensional stability

- Reducing shrinkage / warping

- Increasing chemical resistance

- Increasing heat resistance

- Masking layer lines with a matt surface finish in 3D printed objects

This makes glass fiber reinforced filaments perfect for 3D printing applications that require mechanical

strength and stiffness.

General printing guidelines*

| Nozzle size: ≥ 0.1mm | Layer height: ≥ 0.05mm | Enclosure needed: No |

| Print temp: ± 255 – 295° C | Fan speed: 0 – 30% | Heat bed: ± 90 – 110°C |

*) Above displayed settings are meant as guidance to find your optimal print settings. These ranges in settings should work for most printers,

but please do feel free to experiment outside these ranges if you think it is suitable for your printer. There are a lot of different type of printers,

hot-ends and printer offsets that it is extremely difficult to give an overall one-size-fits-all setting.

Abrasiveness

Please be aware that glass fiber reinforced filaments contain a relatively high concentration of extremely hard glass fibers, which have an abrasive nature. In general these glass fibers will accelerate the nozzle-wear of brass nozzles, much faster than unfilled filaments. We recommend to use ruby nozzles or hardened steel nozzles.

Storage and handling

Filament should be stored at room temperature in a dry and dark place with humidity below 15%. Recommended storage temperature is ca. 18-25°C (64.4 -77.0°F). Keep out of moisture, sunlight and direct heat. When stored properly, product has a shelf life of 24 months. To obtain the best parameters of the printed object, it is recommended to dry the material prior to usage and to 3D print it directly from a dry box.

Product export information

| HS Code: 39169090 | Description: Monofilament for 3D Printing | Origin: European Union |

Safety Datasheet:

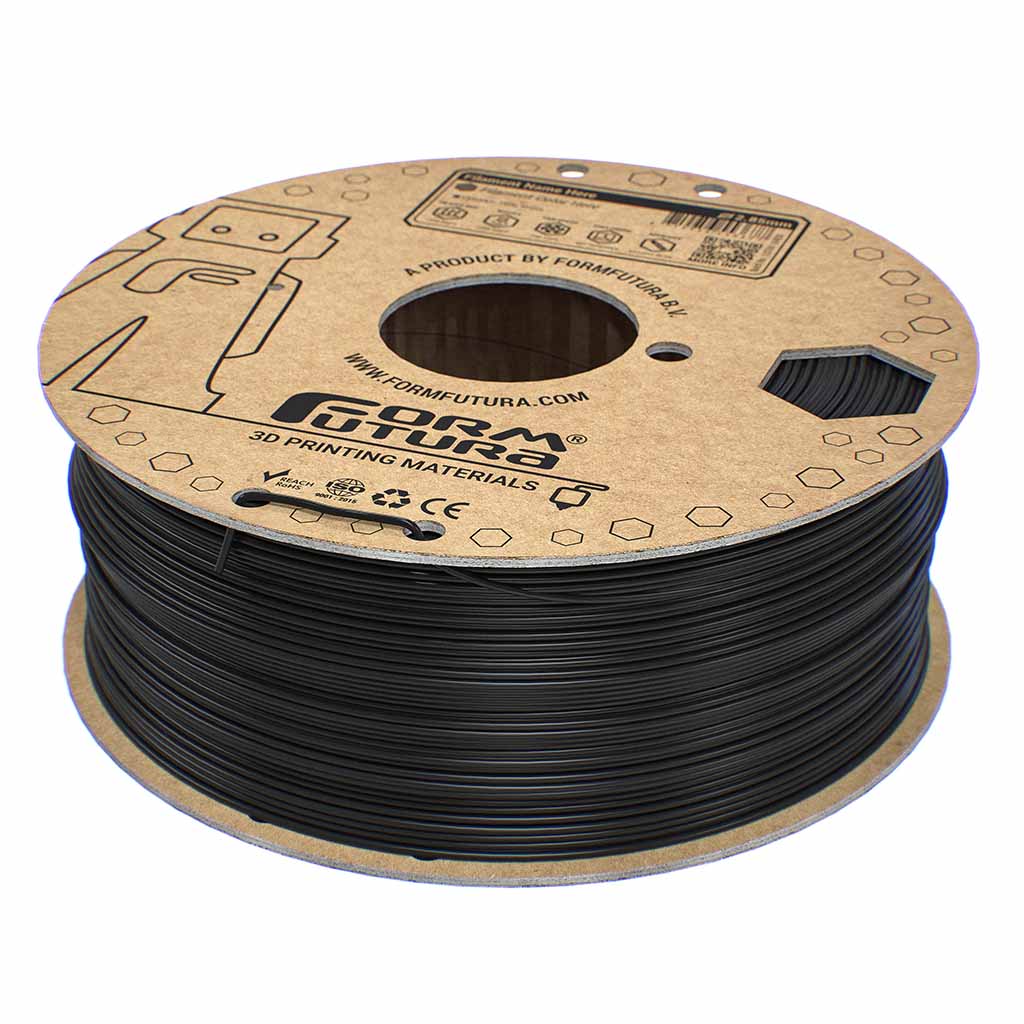

STYX PA6-GF30

STYX PA6-GF30 combines all benefits of STYX PA6 filament with its excellent mechanical, chemical and hygroscopic properties, plus 30% glass fibers.

- Ordered before 15h CET? Ships same business day

- Worldwide shipping with UPS & FedEx

- One-stop shop for 3D printing materials

Featured Products

STYX PA6-GF30

STYX PA6-GF30 combines all benefits of STYX PA6 filament with its excellent mechanical, chemical and hygroscopic properties, plus 30% glass fibers.

If a product is out of stock, it is usually replenished within two weeks.

- Ordered before 15h CET? Ships same business day

- Worldwide shipping with UPS & FedEx

- One-stop shop for 3D printing materials

STYX PA6-CGF is a high-performance glass fiber-reinforced PA6 filament. The added glass fibers make this filament strong and stiff, without being brittle. This engineering filament is very easy to 3D print on open desktop machines. No enclosure, or heated chamber is needed. Its low shrinkage factor and perfect layer adhesion make STYX PA6-GF30 a breeze to print with.

Important key features

- Reinforced with 30% glass fibers

- High compressive strength

- Heat resistant up to 180°C

- High wear, tear, and abrasion resistance

- Excellent chemical resistance

- Easy to print on open desktop 3D printers</>

Suitable applications

- Automotive parts

- Connectors and switches

- Housings for electronic devices

- Gear wheels, bearings, and sliding elements

- 3D printing machinery parts

- Dynamically stressed parts

Glass fiber reinforcement explained

Reinforcing filaments with glass fibers results in great benefits. It combines the unique properties of both materials. The properties of the thermoplastic improve with everything glass fibers offer. Glass fibers offer lots of benefits, such as:

- Increasing stiffness

- Increasing strength

- Increasing dimensional stability

- Reducing shrinkage / warping

- Increasing chemical resistance

- Increasing heat resistance

- Masking layer lines with a matt surface finish in 3D printed objects

This makes glass fiber reinforced filaments perfect for 3D printing applications that require mechanical

strength and stiffness.

General printing guidelines*

| Nozzle size: ≥ 0.1mm | Layer height: ≥ 0.05mm | Enclosure needed: No |

| Print temp: ± 255 – 295° C | Fan speed: 0 – 30% | Heat bed: ± 90 – 110°C |

*) Above displayed settings are meant as guidance to find your optimal print settings. These ranges in settings should work for most printers,

but please do feel free to experiment outside these ranges if you think it is suitable for your printer. There are a lot of different type of printers,

hot-ends and printer offsets that it is extremely difficult to give an overall one-size-fits-all setting.

Abrasiveness

Please be aware that glass fiber reinforced filaments contain a relatively high concentration of extremely hard glass fibers, which have an abrasive nature. In general these glass fibers will accelerate the nozzle-wear of brass nozzles, much faster than unfilled filaments. We recommend to use ruby nozzles or hardened steel nozzles.

Storage and handling

Filament should be stored at room temperature in a dry and dark place with humidity below 15%. Recommended storage temperature is ca. 18-25°C (64.4 -77.0°F). Keep out of moisture, sunlight and direct heat. When stored properly, product has a shelf life of 24 months. To obtain the best parameters of the printed object, it is recommended to dry the material prior to usage and to 3D print it directly from a dry box.

Product export information

| HS Code: 39169090 | Description: Monofilament for 3D Printing | Origin: European Union |

Safety Datasheet: