Key features

- Solvay PPSU inside

- Excellent thermal properties with a glass transition temperature of 220°C.

- Flame retardant (UL 94 V-0) with low smoke evolution and low smoke toxicity

- Superior hydrolytic resistance

- Qualified for repeated steam sterilization (>1000 cycles)

- High Environmental Stress Crack Resistance (ESCR)

- Very high impact strength and high stiffness over a wide temperature range

- Very good resistance against high energy radiation (gamma- and X-rays)

- Good electrical insulating and dielectric properties

Applications

- Industrial applications

- Electronics

- Medical parts

- Aerospace applications

- Automotive

General printing guidelines *

| Nozzle size: ≥ 0.4mm | Layer height: ≥ 0.10mm | Experience level: Expert |

| Print temp: ± 360 – 400° C | Fan speed: 0 – 25% | Drying: +4 hours at max.110°C |

| Heat bed: ≥ 120° C | Enclosure needed: 90°C heated chamber |

Adhesion: EasyFix Nr. VII |

*) Above displayed settings are meant as guidance to find your optimal print settings. These ranges in settings should work for most printers, but please do feel free to experiment outside these parameters if you think it is suitable for your printer. There are a lot of different type of printers, hot-ends and printer offset that it is extremely difficult to give an overall one-size-fits-all setting.

Filament length

| ρ: 1.29 g/cc | 0.2 Kg spool | 0.5 Kg spool | |||

| Ø 1.75mm | ± 64m | ± 161m | |||

| Ø 2.85mm | ± 24m | ± 61m |

Product export information

| HS Code: 39169090 | Description: Monofilament | Country of origin: the Netherlands |

Compliance *

This filament is compliant to below-listed directives and regulations.

- RoHS directive 2011/65/EC

- REACH directive 1907/2006/EC

*) This declaration of conformity to directives and regulations is prepared according to our present standard of knowledge and may be amended if new cognitions are available and applies only for the above-described products.

Safety Datasheet:

PPSU

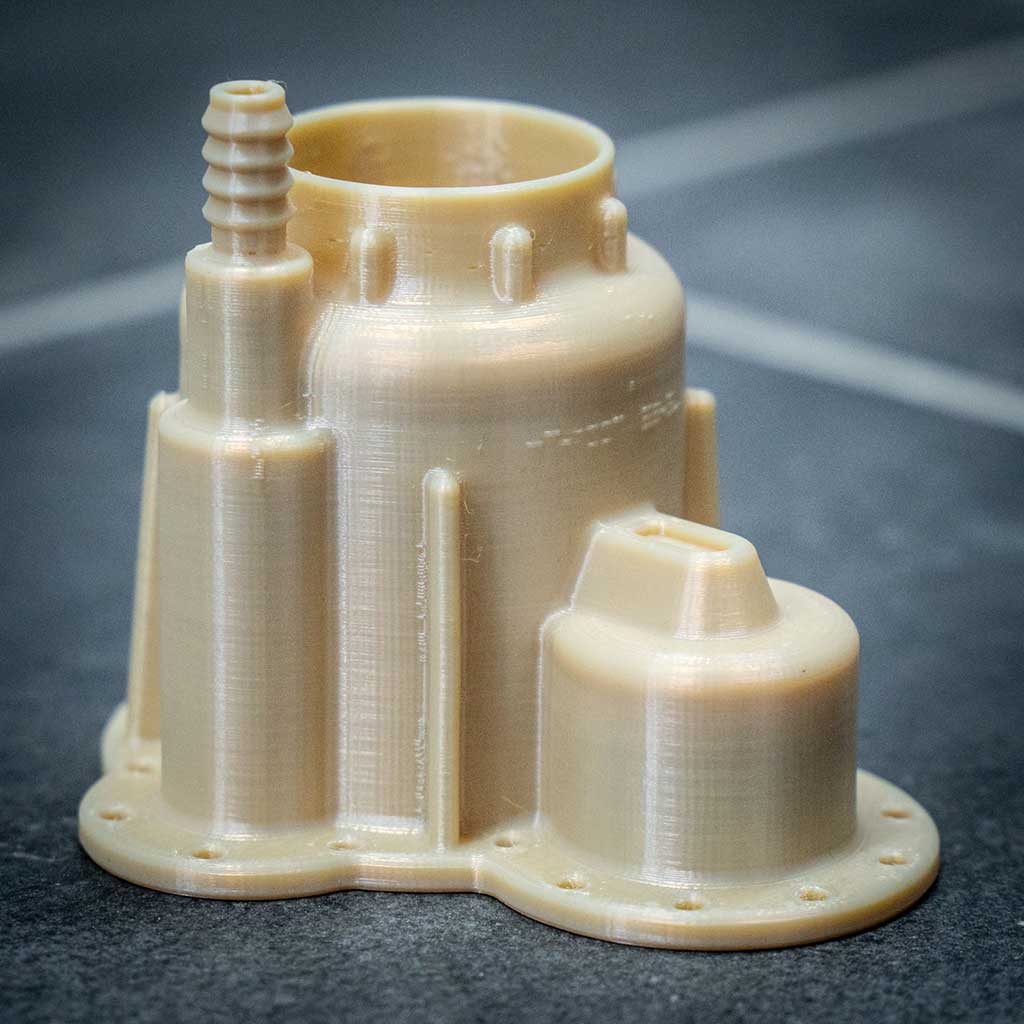

PPSU is an ultra-performance 3D printer filament that can be used to 3D print parts for demanding applications that are chemical resistant and can operate in temperatures up to 180°C.

- Ordered before 15h CET? Ships same business day

- Worldwide shipping with UPS & FedEx

- One-stop shop for 3D printing materials

Featured Products

PPSU

PPSU is an ultra-performance 3D printer filament that can be used to 3D print parts for demanding applications that are chemical resistant and can operate in temperatures up to 180°C.

If a product is out of stock, it is usually replenished within two weeks.

- Ordered before 15h CET? Ships same business day

- Worldwide shipping with UPS & FedEx

- One-stop shop for 3D printing materials

Key features

- Solvay PPSU inside

- Excellent thermal properties with a glass transition temperature of 220°C.

- Flame retardant (UL 94 V-0) with low smoke evolution and low smoke toxicity

- Superior hydrolytic resistance

- Qualified for repeated steam sterilization (>1000 cycles)

- High Environmental Stress Crack Resistance (ESCR)

- Very high impact strength and high stiffness over a wide temperature range

- Very good resistance against high energy radiation (gamma- and X-rays)

- Good electrical insulating and dielectric properties

Applications

- Industrial applications

- Electronics

- Medical parts

- Aerospace applications

- Automotive

General printing guidelines *

| Nozzle size: ≥ 0.4mm | Layer height: ≥ 0.10mm | Experience level: Expert |

| Print temp: ± 360 – 400° C | Fan speed: 0 – 25% | Drying: +4 hours at max.110°C |

| Heat bed: ≥ 120° C | Enclosure needed: 90°C heated chamber |

Adhesion: EasyFix Nr. VII |

*) Above displayed settings are meant as guidance to find your optimal print settings. These ranges in settings should work for most printers, but please do feel free to experiment outside these parameters if you think it is suitable for your printer. There are a lot of different type of printers, hot-ends and printer offset that it is extremely difficult to give an overall one-size-fits-all setting.

Filament length

| ρ: 1.29 g/cc | 0.2 Kg spool | 0.5 Kg spool | |||

| Ø 1.75mm | ± 64m | ± 161m | |||

| Ø 2.85mm | ± 24m | ± 61m |

Product export information

| HS Code: 39169090 | Description: Monofilament | Country of origin: the Netherlands |

Compliance *

This filament is compliant to below-listed directives and regulations.

- RoHS directive 2011/65/EC

- REACH directive 1907/2006/EC

*) This declaration of conformity to directives and regulations is prepared according to our present standard of knowledge and may be amended if new cognitions are available and applies only for the above-described products.

Safety Datasheet: