Interview with Creativity by PH

Transforming Urban Spaces with 3D Printing: Helsingborg’s Iconic Lamp

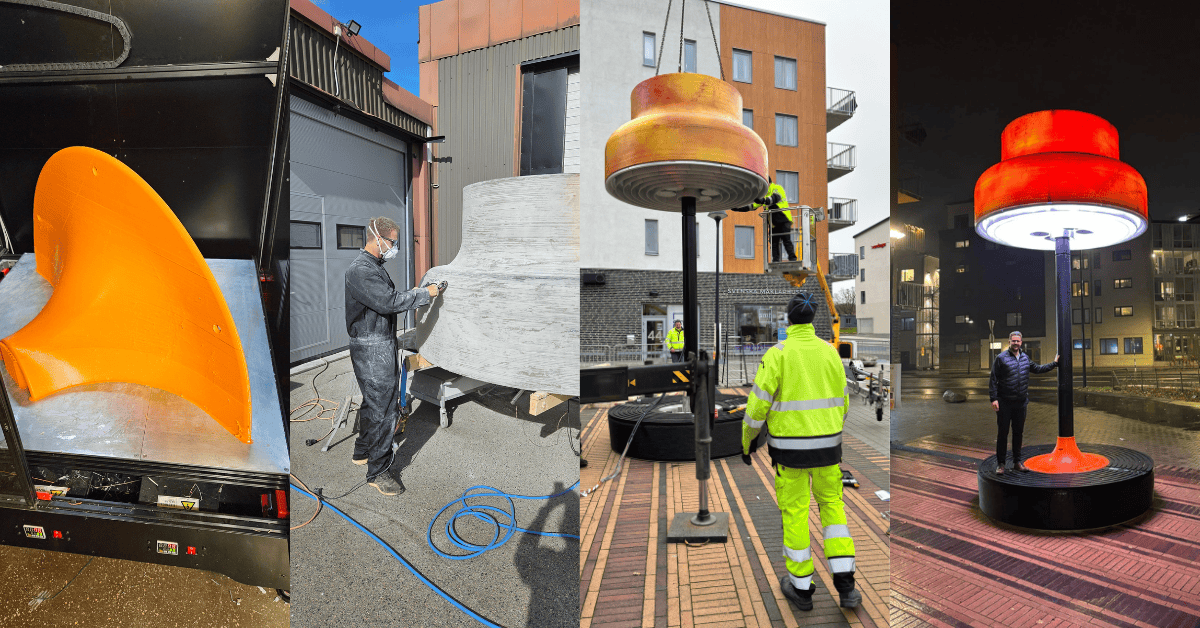

Urban design often calls for a blend of aesthetics, functionality, and community engagement. Helsingborg’s latest project exemplifies this synergy with an innovative approach to public lighting. This massive 3D-printed lamp not only transforms the cityscape but also showcases the boundless potential of additive manufacturing.

For this interview, we once again spoke with Per Hjort from CreativityByPH about his latest project as consultant and 3D print expert for a unique project in the Swedish city of Helsingborg.

A Brighter Future for Helsingborg

Helsingborg, Sweden, embarked on a visionary project as part of its urban renewal initiative. The goal: to reimagine dark, unwelcoming spaces into vibrant hubs of activity. Central to this effort was the creation of a modern reinterpretation of the city’s signature lamp, Boomlingen.

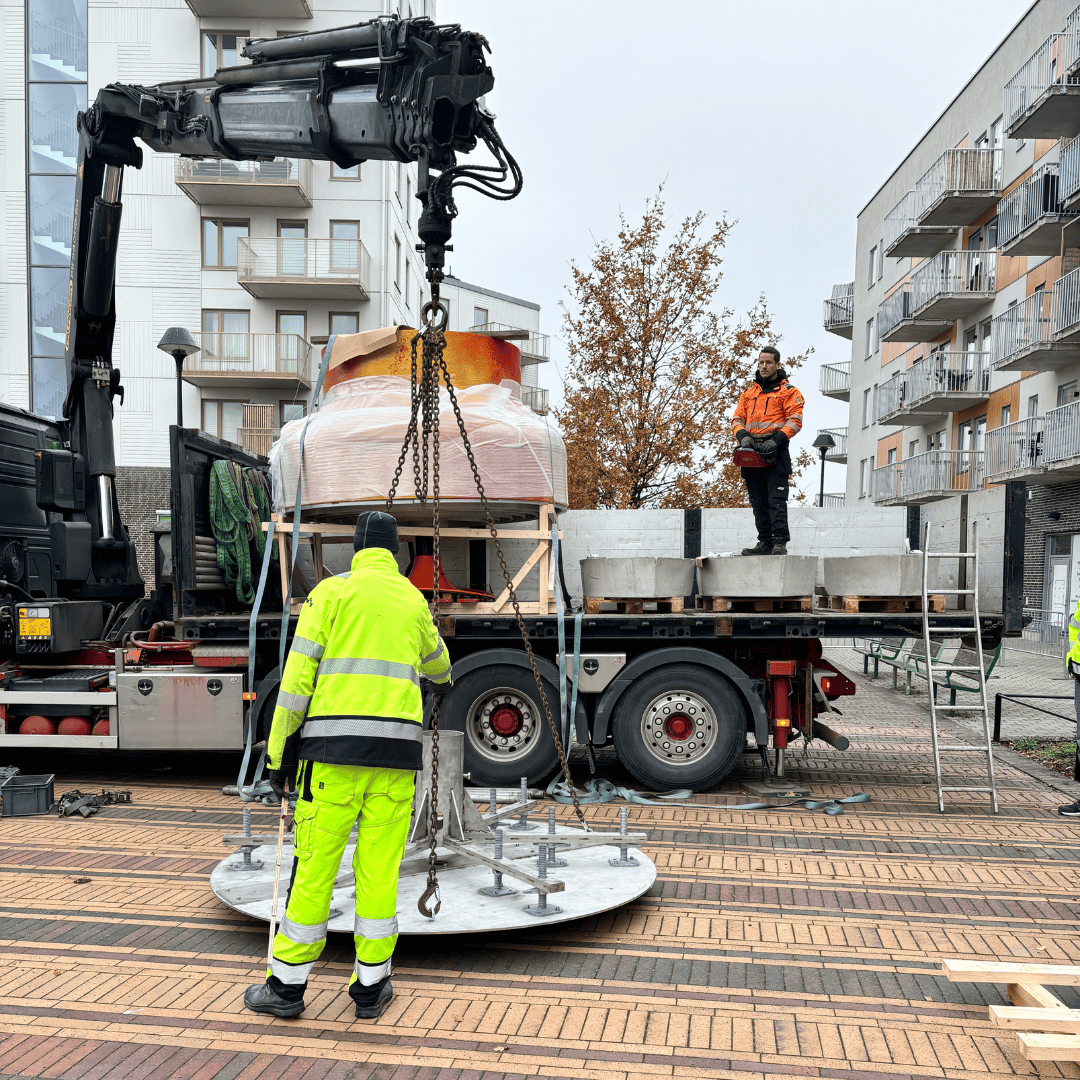

Designed as a movable installation, the lamp was intended to be a cultural icon, bringing light and energy to various parts of the city throughout the year.

Why 3D Printing?

Traditional manufacturing methods, such as fiberglass molding, were initially considered for this project. However, the costs and time constraints of creating large molds led to the adoption of 3D printing. This innovative approach provided several advantages:

- Cost Efficiency: Eliminating the need for molds reduced upfront expenses.

- Rapid Prototyping: Designs could be tested and iterated quickly.

- Customization: The 3D printing process allowed intricate details to be incorporated into the lamp’s design.

The Build: Engineering Marvels in Additive Manufacturing

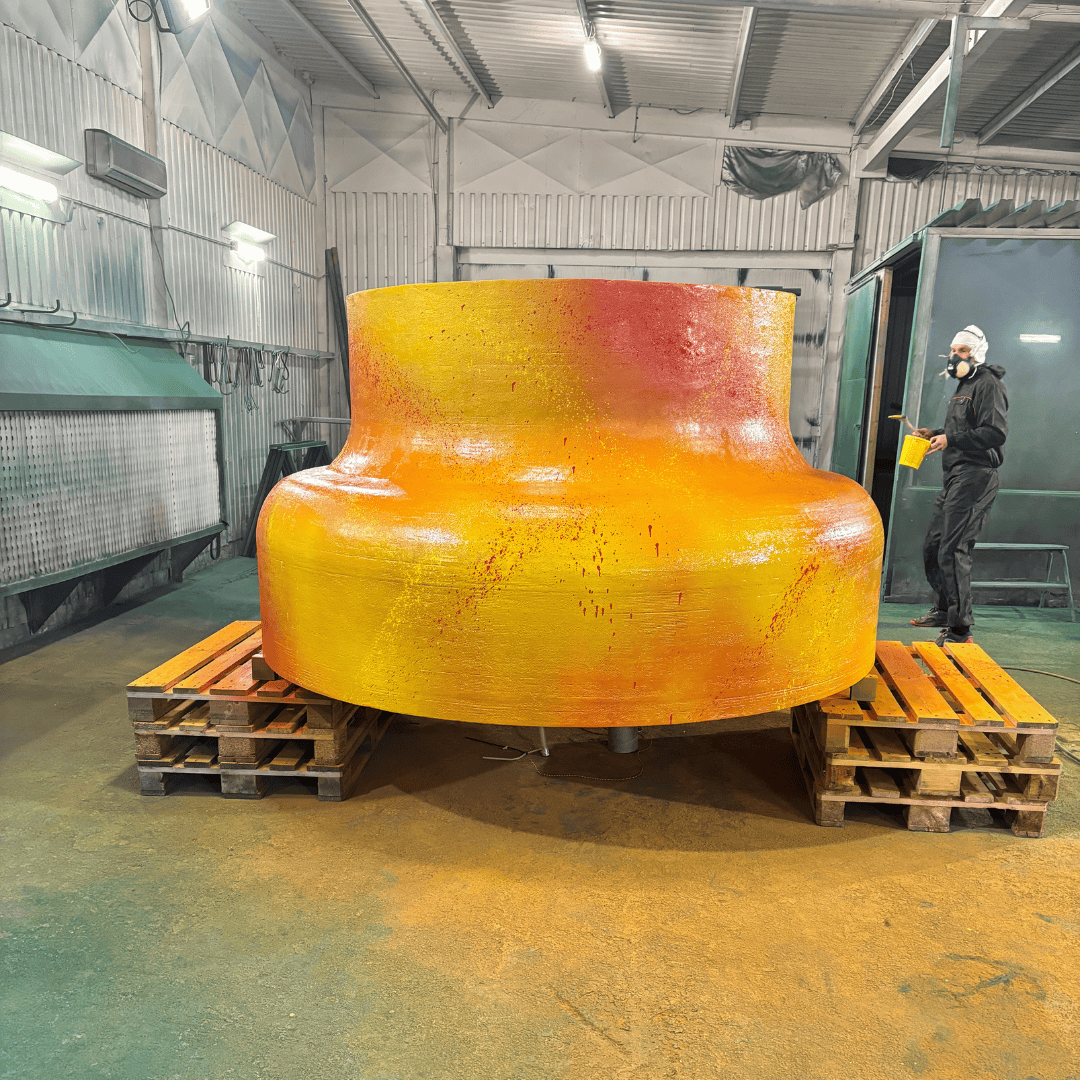

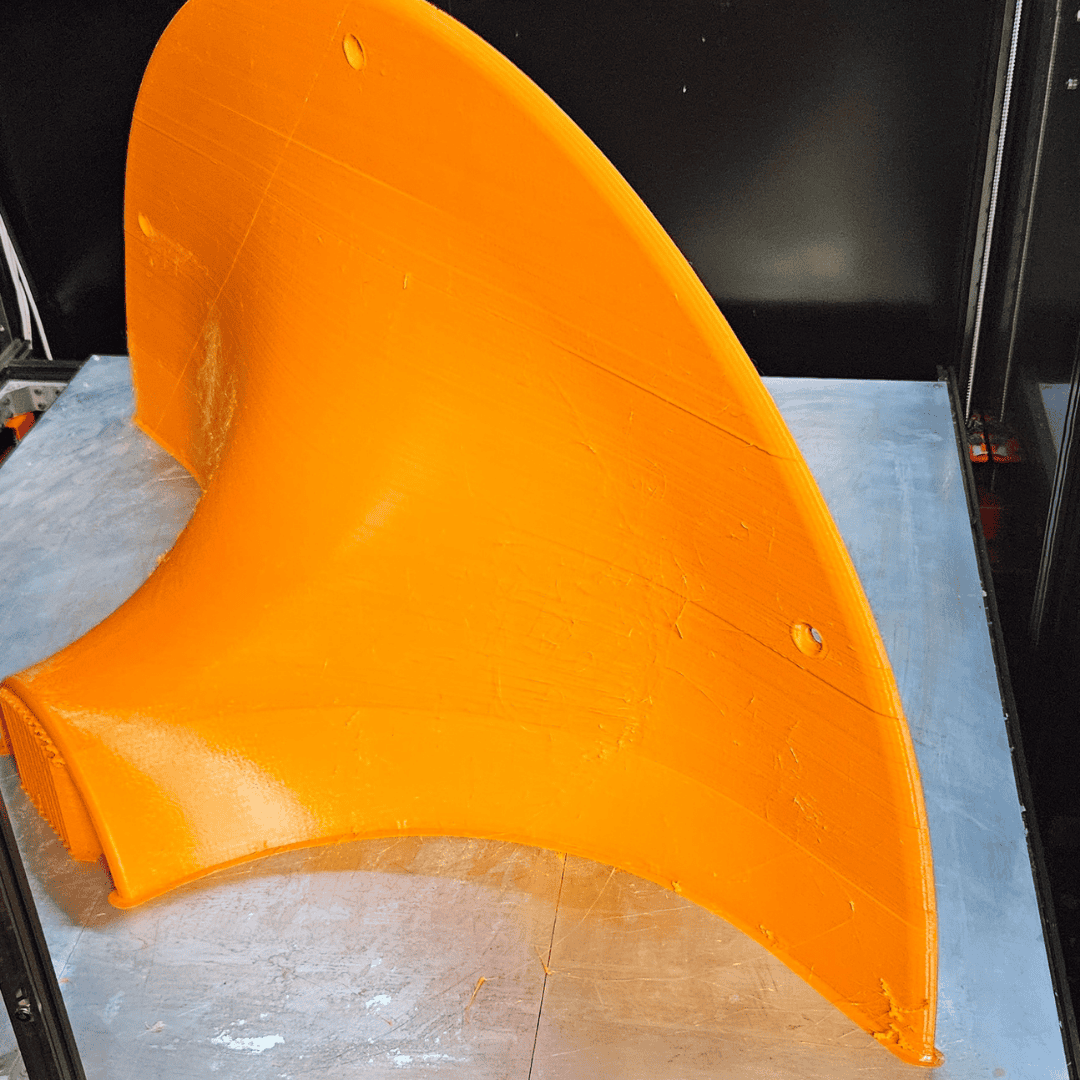

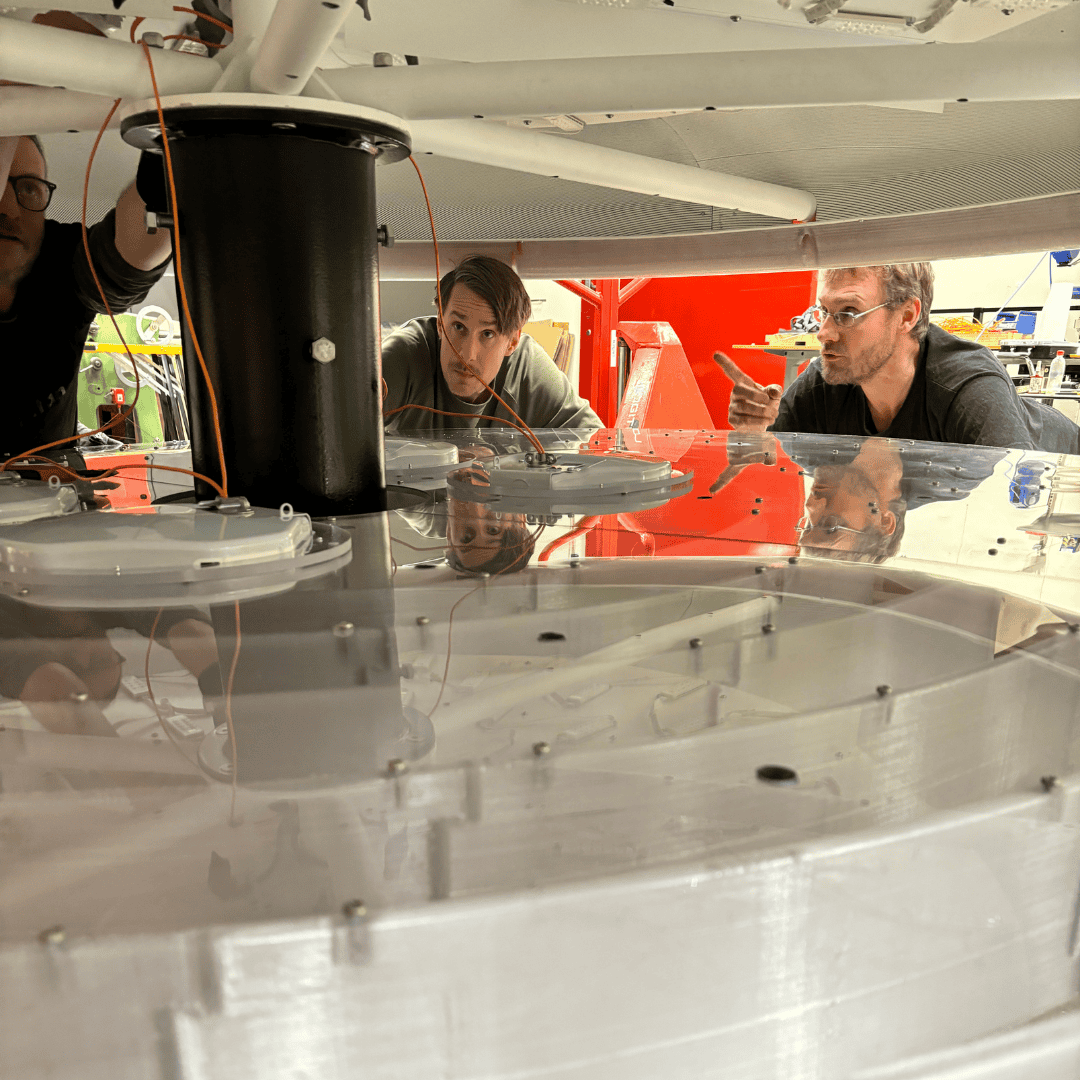

Per tells us that the lamp’s creation involved over 1,200 kg of recycled rPET, printed in multiple components. Key features of the design include:

- Dimensions and Durability: The lampshade alone weighs 366 kg, while the lamp’s structure withstands strong winds, a necessity in Sweden’s climate.

- Functional Innovations: Embedded speakers play ABBA music or user-selected playlists, adding an auditory dimension to its visual appeal.

- Portability: Designed to be moved seasonally, the lamp redefines urban flexibility.

Collaboration was central to this project. Partnerships with Swedish companies and consultation on additive manufacturing ensured the design met both aesthetic and technical standards.

Overcoming Challenges

Per tells us that 3D printing on such a large-scale posed some unique hurdles:

- Material Management: Feeding recycled PETG through a 50-meter pipe required precise drying techniques to prevent moisture absorption.

- Structural Integrity: Extensive wind simulations informed design adjustments, ensuring safety without compromising style.

A Community-Centric Approach

This lamp serves more than its functional purpose. It fosters community engagement by transforming underused spaces and becoming a focal point for social interaction. By choosing recycled materials, the project aligns with Helsingborg’s commitment to sustainability, reducing its environmental footprint while inspiring similar initiatives globally.

Exploring New Horizons in 3D Printing

Helsingborg’s lamp is not the only remarkable achievement in large-scale additive manufacturing. Recent projects include egg-shaped lamps for urban spaces and a mold for a church bell, steeped in historical significance. These endeavors highlight the versatility of 3D printing in addressing diverse creative and functional challenges.

Lighting the Way Forward

This project underscores the potential of 3D printing in reshaping urban spaces. As cities worldwide seek sustainable, adaptable solutions for public infrastructure, Helsingborg’s lamp serves as a shining example of what’s possible when tradition meets technology.

Whether it’s creating iconic installations or enhancing everyday objects, additive manufacturing continues to expand the horizons of design. Inspired by Helsingborg’s success? Explore how you can integrate 3D printing into your next project!

Try 3D printing with PETG

Read our other interview with Per

From Hobbyist to Innovator: Per Hjort’s Passion for 3D Printing

- Posted by FormFutura