From Hobbyist to Innovator: Per Hjort’s Journey of Passion and 3D Printing

This is an interview that took place between Per Hjort from the company CreativitybyPH and FormFutura. Per is a FormFutura reseller located in Sweden. In this interview, we talk about his background in 3D printing, what sparks his interest and what he thinks the future holds for the 3D printing industry. Sharing his incredible journey as a 3D printing enthusiast and designer. His passion, expertise, and unwavering dedication to pushing the boundaries of creativity.

In the rapidly evolving world of 3D printing, one reseller stands out for his commitment to providing top-quality materials to the creative community. Meet Per Hjort, a passionate 3D printing enthusiast, and the driving force behind connecting customers with FormFutura’s exceptional range of filaments, including the captivating wood and stone variants.

My Background in Creative 3D Printing

I’m Per Hjort, and I’ve been deeply involved in the fascinating world of 3D printing for quite some time now. My fascination with 3D printing all began because of my love for creating and building things, especially for the transport and vintage car industries.

My prized possession is an old Land Rover, but unfortunately, I had an accident at work that kept me away from tinkering with my car. This setback pushed me to explore new avenues, and that’s when I stumbled upon 3D printing.

Creativity by PH

I am the founder of Creativity by PH, a company where I am passionate about exploring and developing additive manufacturing and 3D printing. I am a FormFutura reseller, and provide 3D printing services to help achieve business goals, I am specialized in areas like :

- Additive Manufacturing Design Rules Training: I have a solid knowledge of the specific design rules that apply to additive manufacturing and offer training to help my clients understand these principles and how they can be used to optimize their products.

- 3D Printer and Software Training: I have an in-depth understanding of both 3D printing hardware and software and offer 3D printer and related software training to ensure my clients get the best possible results from their machines.

- Print-on-demand: At Creativity by PH I offer a flexible and efficient print-on-demand service. I understand the importance of offering fast and reliable service, regardless of whether it is a one-off prototype or small series of products.

- Mass production of parts with FDM technology

Embracing 3D Printing for Transformative Projects

3D printing has always fascinated me with its endless possibilities. The ability to bring imagination to life through tangible creations is truly captivating. Being the curious person I am, I decided to give it a shot and see if I could optimize my Land Rover’s parts through 3D printing.

The journey wasn’t without its challenges, but I dived headfirst into learning CAD drawing using Fusion 360.

Let me tell you, I made my fair share of mistakes, just like any beginner would. However, those mistakes became valuable lessons as I immersed myself in the world of 3D design.

During this exciting phase, I found solace in the vibrant 3D printing communities. There, I engaged in intriguing conversations and absorbed a wealth of knowledge. One such inspiring encounter was with Mittram, a renowned 3D printing YouTuber. His expertise and world record for speed printing fueled my creative thinking, encouraging me to optimize and model my designs for better and faster 3D printing results.

As the years went by, my passion for 3D printing grew exponentially. While I had my full-time job as a panel beater, fixing cars during the day, my evenings and nights were gradually taken over by 3D printing projects. It reached a point where the time I spent on 3D printing rivaled that of my day job. My wife, rightfully concerned about the balance in my life, urged me to make a decision. I knew I had to take action; this creative pursuit couldn’t just be a side hobby anymore.

So, I decided to invest in myself and my newfound passion. I enrolled in an education program focusing specifically on CAD drawing for additive manufacturing. This was a crucial step to enhance my skills and knowledge, allowing me to take my 3D printing endeavors to the next level. It was a leap of faith, but I was determined to turn my passion into something more significant, both creatively and professionally.

Services and store

I saw opportunity to start my business as the demand for 3D printed services and products grew. My goal is to provide a one-stop shop for all things 3D printing. I offer a variety of high-quality 3D printers, filaments, and spare parts. I also sell a variety of 3D printed products, including toys, games, and decorations. Additionally, I offer a selection of IKEA Skådis accessories and my own merchandise.

High quality and consistent colors

As a designer and maker, I am always looking for high-quality materials that I can trust to deliver consistent results. I have been using FormFutura 3D printing materials for several years now, and I have always been impressed with their quality and consistency. The colors are always vibrant and true to life, and the materials are easy to work with. This is especially important for me, as I often use FormFutura materials to create custom designs for my clients.

Sustainable materials

I am also very passionate about sustainability, and I am always looking for ways to reduce my environmental impact. I am proud to say that FormFutura is a company that shares my commitment to sustainability. They offer a wide range of sustainable materials, including rPLA, which is made from recycled plastic bottles. I use rPLA whenever possible, and I am always impressed with the quality of the prints.

My Proudest Project Accomplishment

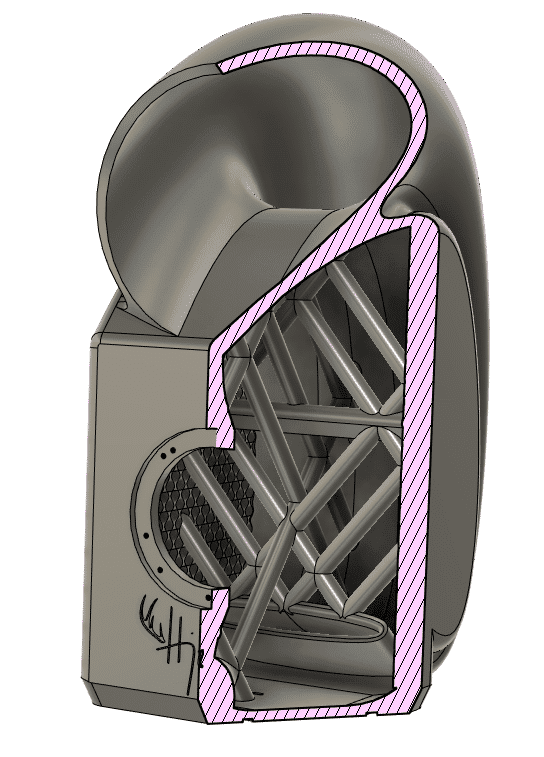

One of my most treasured and time-consuming projects has been designing a HIFI speaker that defies traditional manufacturing methods. I wanted a speaker with exceptional sound quality, a classic yet unique design, and dimensions that could only be achieved through 3D printing. The result was a strikingly unconventional speaker with a square-like box shape and a horn in the back to enhance lower frequencies.

Throughout the iterative process, I experimented with different materials, like epoxy and sand, to optimize the speaker’s acoustics. It was a journey of refinement and innovation, and 3D printing played a vital role in bringing my vision to life. The intricate shape of the speaker, inspired by the organic curves of the human ear, wouldn’t have been feasible with any other manufacturing method.

I choose to use FormFutura rPLA. The main reason is that it’s made from renewed materials and still has a high quality. So I get the most sustainable PLA on the market with excellent end-results. It’s affordable combined with sustainability. Win-win

The dedication and effort I poured into perfecting this speaker design were substantial. Across numerous iterations, I invested approximately 210 hours to achieve the desired outcome. Throughout the process, I collaborated with a company that meticulously evaluated each design, measuring acoustics and performance.

Additionally, I explored various drivers, trying out nearly 10 different ones before finding the perfect match. In terms of costs, considering only the expenses incurred for external services and driver purchases, it amounted to around 100,000 Swedish kronor, roughly equivalent to 10,000 euros. However, this figure does not encompass the countless hours I spent refining the design and bringing my vision to life, which truly represents the heart and soul of this remarkable project.

Overcoming Challenges and Pioneering

I’ve encountered several challenges while utilizing 3D printing for my creative projects, especially when dealing with intricate designs or large-scale production. One significant hurdle is convincing people that certain designs can be tricky to produce, even with advanced printers. I often encounter issues with support structures, especially when dealing with one-off prints or prototypes for companies. Educating industrial designers about the need to design with 3D printing in mind, such as avoiding the need for support structures and understanding the benefits of thicker walls and textures, can be quite a task.

I believe in pushing the limits of my printers to achieve higher speeds and productivity. My goal is to print at least 100 grams per hour, which necessitates pushing the printers to their maximum capabilities. However, this endeavor comes with its own set of challenges. Sometimes, the designs I attempt to print at such high speeds are not feasible due to the printers’ limitations.

Nevertheless, I continuously strive to optimize the printers and enhance their precision and speed, ultimately aiming to deliver the best results to my clients.

Regarding pricing, I charge based on the amount of material used for each print job. Hence, the faster I print, the more economically viable it becomes for both myself and my clients. Having multiple printers operating at high speeds enables me to handle larger projects efficiently. While the exact pricing details may be private, this approach allows me to offer competitive rates and deliver quality results in a timely manner.

The material FormFutura supplies has a high quality and there is a higher consistency in the colors. Meaning that if I order a white filament now and then again in six months, the color is almost identical. This minimizes the risk of receiving two completely different shades of white.

As the Founder of CreativitybyPH it is important to me to have a supplier that I can trust and that can deliver a product that I’m happy with.

Unleashing Boundless Imagination

The impact of 3D printing on my design process and capabilities was mind-blowing. Before having access to 3D printers, I had to rely on traditional methods like welding and shaping metal, which limited my creative possibilities. However, when I first experienced the potential of 3D printing, everything changed. I remember one of my early projects, where I designed mounting points for the intake in my car’s engine bay. It was an exhilarating moment when the design I envisioned actually worked in reality, despite some minor issues.

From that point on, every project became a blend of excitement and routine. While I no longer experienced the same initial “wow” moments, every design presented new challenges and possibilities. 3D printing opened doors I couldn’t have imagined before. One project that truly amazed me was creating a gripper for a production line. Previously, it took an entire hour to assemble the gripper using CNC-milled aluminum and tubes. With 3D printing, we could use tough resin, which drastically reduced assembly time to just 5 to 10 minutes.

The impact was astounding. We saved up to 93% of weight and achieved a remarkable cost reduction. This 3D-printed gripper outperformed the traditional CNC-milled one, which cost around 2500 euros to produce, while our solution only cost around 50 euros. The realization that my design significantly improved efficiency and cost-effectiveness for the production line was truly gratifying.

“Why there are still CNC parts for me is just mind-blowing, why is not everyone using this”

– Per Hjort

Seeing the potential of 3D printing to revolutionize manufacturing processes, it’s astonishing that not everyone has embraced this technology yet. It’s an incredible tool that offers countless advantages in terms of design flexibility, speed, and cost-effectiveness. As I continue to explore and push the boundaries of 3D printing, I am determined to unlock its potential to benefit industries worldwide.

As a private reseller, I wanted to increase my portfolio and offer my clients and suppliers the same high quality, high ranged, products that I use myself. FormFutura also invests in many initiatives that I can support as a reseller. And together with FormFutura we believe that we can contribute to creating a more sustainable environment.

Envisioning the Future of 3D Printing

I wholeheartedly believe that designers should embrace the vast possibilities of 3D printing and explore different textures and organic shapes in their designs. Creating something unique and creative sets a design apart from the standard square or honeycomb patterns. While it may be time-consuming, investing effort into designing textures and intricate shapes ultimately yields standout results that catch people’s attention.

In terms of future applications, I’m particularly excited about the growing interest from architects and lawyers. They are discovering the potential of 3D printing to create showpieces and models that were previously unfeasible with traditional materials like wood. This trend has led to an increase in architect clients, as well as lawyers seeking to present evidence in court through 3D printed models.

I value the personal connection and trust that comes with being a small, intimate company. My clients appreciate that I’m the sole person handling their projects, ensuring confidentiality and dedication to achieving their vision. Being able to deliver a design where clients can say, “Yes, Per created this masterpiece,” instead of it being the result of a team of 200 designers, adds a level of authenticity and craftsmanship that resonates with my clientele.

As I continue to grow and evolve in my role as a designer and 3D printing expert, I find joy in educating other designers about implementing 3D printing into their projects. Witnessing the transformative power of 3D printing in various industries and helping others unlock its potential is incredibly fulfilling. I’m excited to see where this journey takes me and the impact I can make in the world of design and innovation.

Unlocking Your Creative Potential

Currently, I’m working on a groundbreaking project with a lawyer client, aiming to revolutionize the way legal presentations are done in the courtroom. This innovative approach involves creating 3D printed models that will put my client miles ahead of their competition in terms of presentation and efficiency. While the project has been challenging and secretive, the personalized touch and attention to detail I provide as a one-man company have been highly appreciated by my clients.

One of the most significant breakthroughs in my creative process came when I stopped fixating on the cost and print time of 3D printing. Letting go of those concerns allowed me to unleash my creativity fully. I stopped being afraid of attempting ambitious projects, even if they took several days to print.

For instance, my speaker design, which weighs around eight kilograms, occasionally failed during the last 10% of the print. Initially, it was frustrating, but I learned to accept that failures are part of the process. If something goes wrong, I can always fix it with some glue and lacquer. The key was not letting the fear of failure hold me back from exploring new ideas and designs.

Another crucial aspect was learning to design for the goal, not the constraints of my 3D printer. I shifted my focus from designing within the limitations of the machine to pursuing my vision without hesitation. It’s essential to identify what you want to create and then work around any constraints that may arise. This approach allowed me to bring my ideas to life and create unique designs without feeling restricted.

Iteration has been a significant part of my creative journey. I’ve learned that sometimes it takes multiple attempts to get a design right. I’m not discouraged by initial failures because they lead me closer to the perfect result. Embracing this iterative process has been liberating, as it gives me the freedom to experiment and refine my designs until they match my vision.

Of course, there have been moments of frustration and irritation along the way, but that’s part of the creative process. I remind myself that even the best designs require effort, time, and a willingness to persevere through challenges. And in the end, the satisfaction of seeing my ideas come to life and the inspiration it brings outweigh any hurdles I encounter.

For any aspiring 3D designers, my advice would be to let go of fear, start designing for your goals, and don’t be afraid to iterate and refine your work. Embrace failures as stepping stones toward success, and most importantly, never lose sight of the joy and inspiration that comes from the creative journey. That’s what keeps the passion for 3D printing and design alive and flourishing.

Conclusion

In conclusion, we want to extend our heartfelt gratitude to Per Hjort for sharing his incredible journey as a 3D printing enthusiast and designer. His passion, expertise, and unwavering dedication to pushing the boundaries of creativity have left us truly inspired. From groundbreaking projects to innovative approaches, Per’s work showcases the limitless possibilities that 3D printing offers to the world of design.

If you’re eager to explore more of Per’s remarkable creations and want to learn from his wealth of knowledge, be sure to visit his website at https://www.creativitybyph.com. You can also connect with him on Facebook at https://www.facebook.com/creativitybyPH, where you’ll find updates on his latest projects and insights into the ever-evolving world of 3D printing.

For a deeper dive into one of his most fascinating projects, check out the blog about the HIFI speaker journey, Click Here. Discover the meticulous process of transforming an idea into reality, and witness the magic of 3D printing bringing this innovative speaker design to life.

Once again, thank you, Per Hjort, for inspiring us with your creativity, expertise, and dedication to advancing the world of 3D printing. We eagerly look forward to witnessing the exciting future projects that will undoubtedly continue to push the boundaries of innovation. Keep creating and shaping the world with your incredible designs!

Contact

W: www.creativitybyph.com

E: per@creativitybyph.com

P: (+46) 72 – 322 81 82