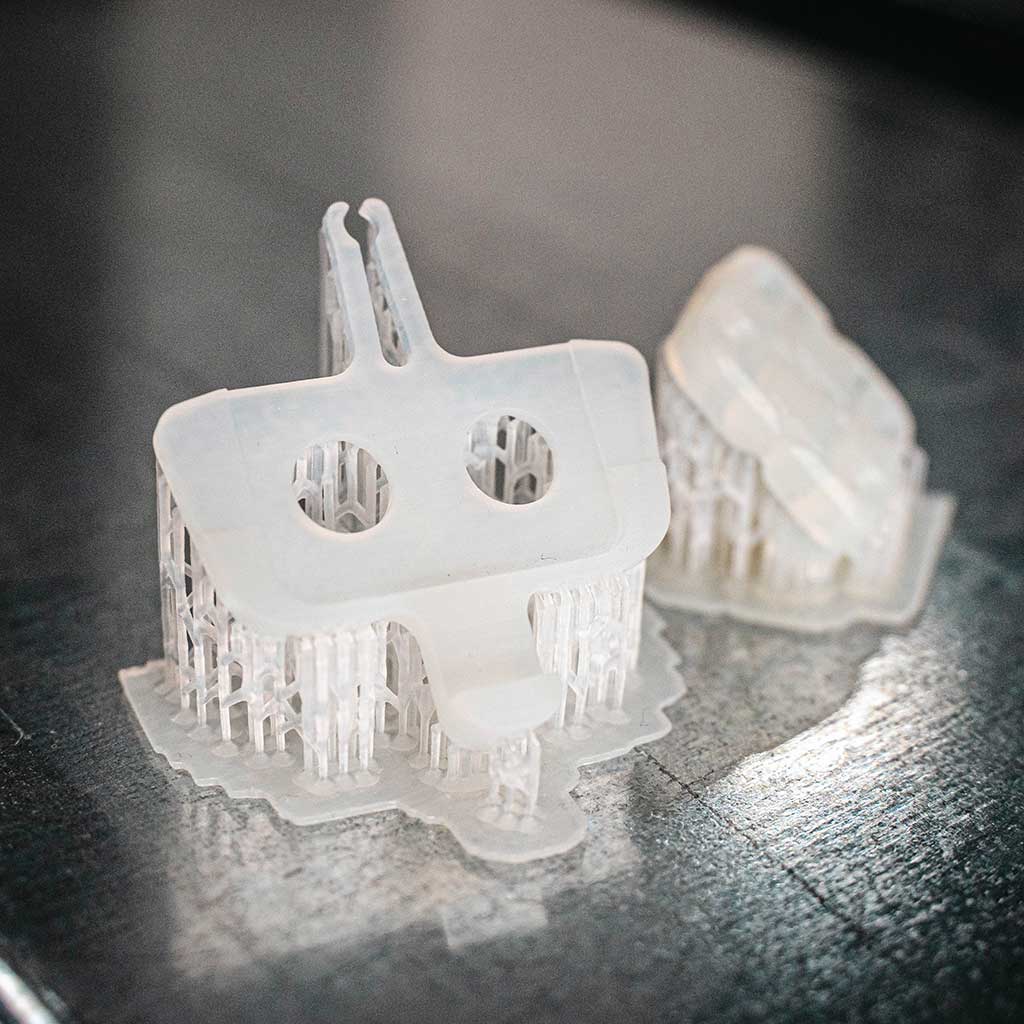

Our Engineering LCD Resin – Tough is an impact resistant 3D printing resin that combines toughness with durability. It also exhibits outstanding scratch resistance properties.

The resin is ideal for 3D printing functional prototypes and operational parts. It can be used for various applications, ranging from household parts

to industrial replacement parts.

Key features

- High impact resistance

- Durable

- Good fatigue resistance

- Excellent scratch resistance

- High dimensional accuracy and low shrinkage

- Almost odorless processing

- Compatible with all open-source SLA, DLP, and LCD 3D printers in the range of 385 – 405nm

Applications

- Snap-fit assemblies

- Tooling

- Functional prototyping

- Protective cases

- Short-run manufacturing

Comparison of technical specifications for FormFutura Engineering LCD Series 3D printing resin

The table below shows the technical data for all our Engineering LCD resins and makes it easy to compare resins based on their mechanical properties.

Please note that the above-displayed values can vary with individual machine processing, post-curing parts, geometry, print orientation, print settings, and temperature.

Preparation(s) before starting to print

- Shake the bottle for at least 2 minutes before each use.

- After shaking the bottle, leave the resin to rest for 10 minutes to let air bubbles get out of the resin

- The resin can be poured back from the vat into the bottle once your print is finished

- Always use protective measurements like safety glasses and nitrile gloves when handling resins.

Post-processing

- We do advise you to post-process your 3D print in order to achieve the material properties

- Rinse your 3D printed object in IPA or (Bio)Ethanol for approximately 5 minutes

- An ultrasonic cleaner is preferred/recommended

- Make sure that IPA and/or (Bio)Ethanol rinsed objects are perfectly dry before further post-curing

- Place the rinsed parts in a well-ventilated area for at least 30 minutes, or use pressurized air for at least 2 minutes

- Cure your object in a high power curing chamber for approximately 20-30 minutes at 65° C

- The preferred curing wavelength is between 300-410nm

Safety

Please always be aware that when 3D printing with resins that you are working with chemicals and that you should always be cautious and use the personal protective equipment as stipulated in our safety data sheets.

- Always wear Respiratory Protection when sanding/cutting the resin object.

- Always use nitrile gloves when handling resins and uncured resin objects.

Product export information

| HS Code: 2916140090 | Description: Resin for 3D Printing | Country of origin: the Netherlands |

Safety Datasheet:

Engineering LCD Resin – Tough

Engineering LCD Series – Tough Resin is an extremely impact resistant 3D printing resin that combines toughness with durability and displays outstanding scratch resistance properties.

- Ordered before 15h CET? Ships same business day

- Worldwide shipping with UPS & FedEx

- One-stop shop for 3D printing materials

Featured Products

Engineering LCD Resin – Tough

Engineering LCD Series – Tough Resin is an extremely impact resistant 3D printing resin that combines toughness with durability and displays outstanding scratch resistance properties.

If a product is out of stock, it is usually replenished within two weeks.

- Ordered before 15h CET? Ships same business day

- Worldwide shipping with UPS & FedEx

- One-stop shop for 3D printing materials

Our Engineering LCD Resin – Tough is an impact resistant 3D printing resin that combines toughness with durability. It also exhibits outstanding scratch resistance properties.

The resin is ideal for 3D printing functional prototypes and operational parts. It can be used for various applications, ranging from household parts

to industrial replacement parts.

Key features

- High impact resistance

- Durable

- Good fatigue resistance

- Excellent scratch resistance

- High dimensional accuracy and low shrinkage

- Almost odorless processing

- Compatible with all open-source SLA, DLP, and LCD 3D printers in the range of 385 – 405nm

Applications

- Snap-fit assemblies

- Tooling

- Functional prototyping

- Protective cases

- Short-run manufacturing

Comparison of technical specifications for FormFutura Engineering LCD Series 3D printing resin

The table below shows the technical data for all our Engineering LCD resins and makes it easy to compare resins based on their mechanical properties.

Please note that the above-displayed values can vary with individual machine processing, post-curing parts, geometry, print orientation, print settings, and temperature.

Preparation(s) before starting to print

- Shake the bottle for at least 2 minutes before each use.

- After shaking the bottle, leave the resin to rest for 10 minutes to let air bubbles get out of the resin

- The resin can be poured back from the vat into the bottle once your print is finished

- Always use protective measurements like safety glasses and nitrile gloves when handling resins.

Post-processing

- We do advise you to post-process your 3D print in order to achieve the material properties

- Rinse your 3D printed object in IPA or (Bio)Ethanol for approximately 5 minutes

- An ultrasonic cleaner is preferred/recommended

- Make sure that IPA and/or (Bio)Ethanol rinsed objects are perfectly dry before further post-curing

- Place the rinsed parts in a well-ventilated area for at least 30 minutes, or use pressurized air for at least 2 minutes

- Cure your object in a high power curing chamber for approximately 20-30 minutes at 65° C

- The preferred curing wavelength is between 300-410nm

Safety

Please always be aware that when 3D printing with resins that you are working with chemicals and that you should always be cautious and use the personal protective equipment as stipulated in our safety data sheets.

- Always wear Respiratory Protection when sanding/cutting the resin object.

- Always use nitrile gloves when handling resins and uncured resin objects.

Product export information

| HS Code: 2916140090 | Description: Resin for 3D Printing | Country of origin: the Netherlands |

Safety Datasheet: