Crafting dreams onto two wheels – Interview with St. Joris Cycles

Estimated reading time: 6 minutes

Who are St Joris Cycles

Founded out of a love for cycling, St Joris Cycles has been in operation for 13 years. Employing various 3D printing techniques that have consistently set St Joris Cycles apart in the creation of distinctive, and bespoke bicycles. In fact, St Joris Cycles is the only company applying 3D printing in its production process. They care about the big picture and have en obsessive-like attention for detail.

Creating Custom Bikes

St Joris Cycles is specialized in creating custom-made racing bikes. This involves starting with a bike fitting, a process undertaken with an expert in Nijmegen. The fitting is important to optimize the sitting position and optimal steering characteristics. These factors, for example the lenght of your legs, how flexible your back is are all derived from the bike fitting, and guide the second part, which is designing the bike.

Once an individual is placed in the ideal position on the bike, we obtain crucial data. We want to know where the hands grip the handlebars, the position of the saddle, and the position of the pedal in relation to the pedal surface. These three points are important to determine the positions on the bike.

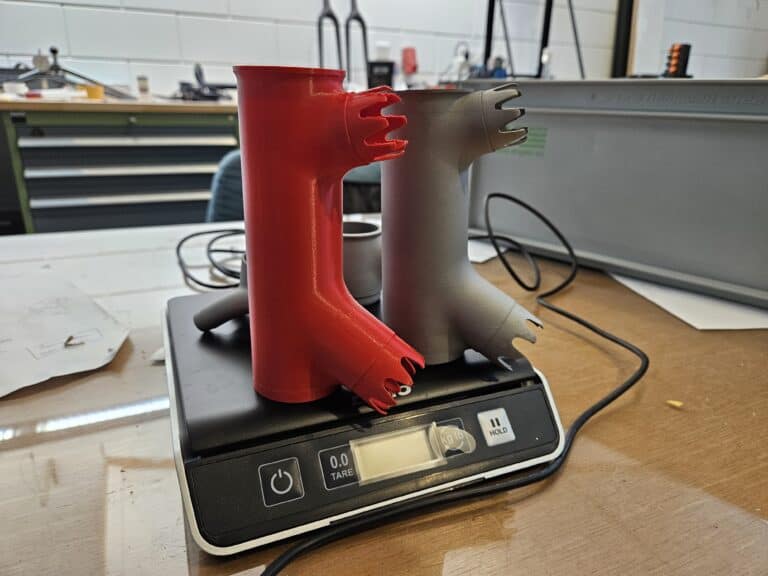

With this data, we can design the frame, and adjust the distance between the wheels, angles, and the type of fork. These parameters ultimately determine how the bike steers. Customers leave our shop with a bike that deviates only plus or minus 1 mm from the ideal bike fit. This is the best tolerance we can achieve. After completing the design, customers decide on the appearance before we create the final frame.

The production time varies between 8 and 12 months. The entire process includes frame creation, component fabrication, painting, and anti-corrosion treatment.

How does FormFutura play a role in all of this?

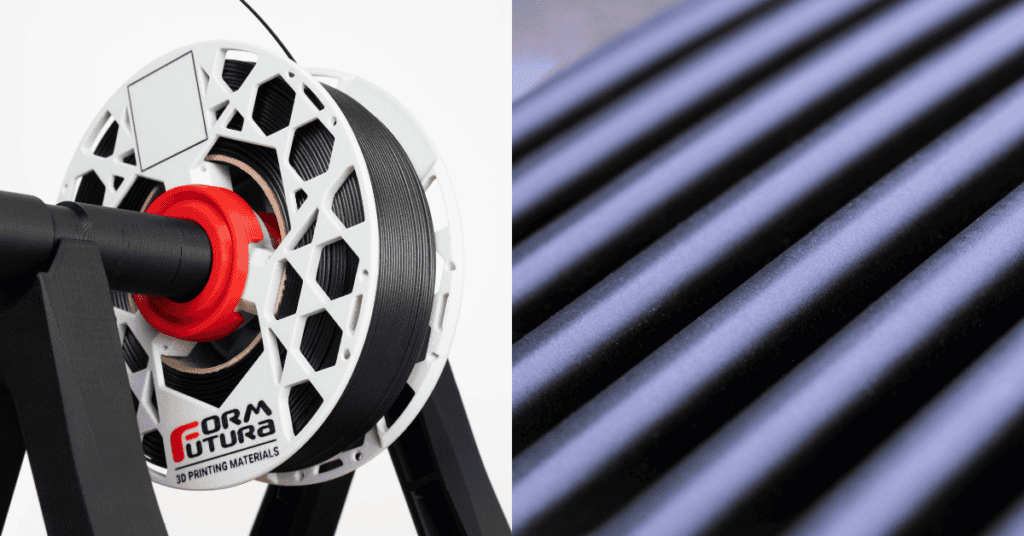

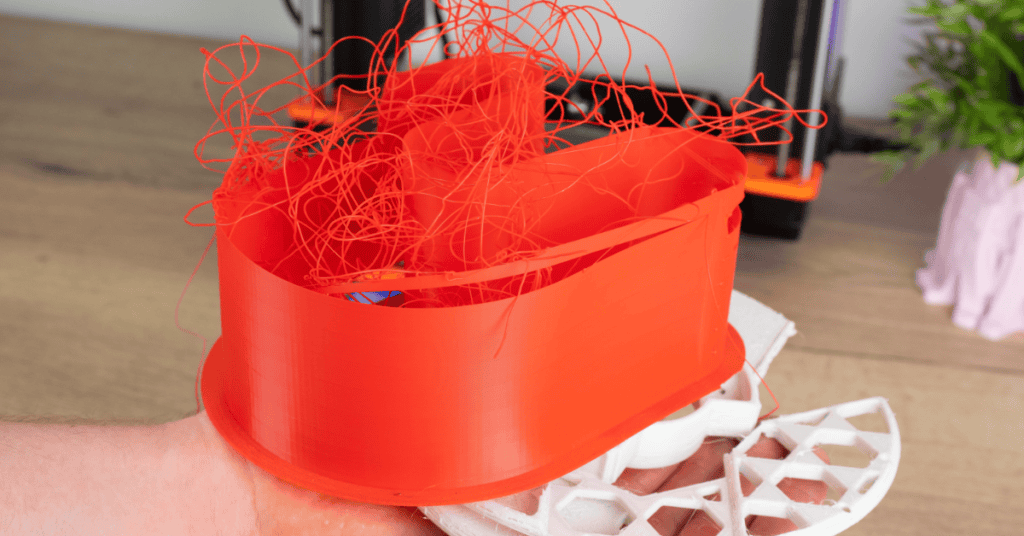

FormFutura plays a crucial role in our 3D printing process by providing us with high-quality plastics. We initially encountered issues with our filaments from a local supplier, which prompted us to explore alternative options. Upon FormFutura's recommendation, we switched to their standard PLA filaments, which have consistently delivered exceptional printing results.

Primarily, we utilize these plastics for prototype development. The rapid prototyping capabilities of 3D printing allow us to iterate designs efficiently, significantly streamlining our innovation process.

3D printing, with its ability to create integrated components, further enhances St Joris' distinctiveness. This technology empowers us to produce custom bikes that would be impossible using traditional methods.

While we are pleased with the performance of our current 3D printing setup, we acknowledge the limitations of print speed, particularly in plastic. Implementing a faster printer would undoubtedly enhance our workflow. Ultimately, our aspiration lies in achieving near-instantaneous translation of digital designs into physical prototypes, a goal that lies within the realm of possibility but remains an ambitious endeavor.

How do you see the future of 3D printing in your process?

3D printing is still a growing and evolving market. Printers are getting faster, and I also notice that the 3D printers entering the market are more towards plug-and-play. We see possibilities to improve the speed of 3D printing, especially in plastic. It would be interesting to explore how we can implement faster printers to increase efficiency. We aim to continue innovating and embracing new technologies to optimize our process.

Having a metal printer or an SLA machine is a significant investment. For the number of bikes we make per year (25), it's not feasible to make such investments. However, I believe 3D printing will be an integral part of many production chains within the next 10 years. We want to work with local partners, and currently, I print in Europe, although not mostly in the Netherlands.

Who Are These Bikes made for?

These are for people who have been cycling their whole lives, who have seen all kinds of bikes. They may have ridden steel bikes in the 1980s, then switched to aluminum from Asia, followed the hype and started riding carbon bikes, and now want something truly customized to their size and preferences.

Do you think we will eventually have fully 3D-printed bikes?

Yes, some companies have already done that, and there are demonstrations where it's possible. Personally, I think it might work for, say, a city bike where you don't necessarily look at weight and ride characteristics. But for enthusiast racing bikes, those factors do play a role. The materials currently used in these bikes are of very high quality and have specific properties. The strength, for example, is 3.5 times higher than the metal currently being printed. So, due to the production process, many more materials would need to be added if you wanted to print this. And then you also lose a lot of the comfort properties due to the large wall thickness. So, I don't see it happening anytime soon. People often ask me that question, but I think it won't happen in the next 20 years.

Of course, we have many recently developed materials like carbon fibre and fibreglass. These materials are often lighter but strong in their own way. If we find a solution to make the layers between 3D-printed objects just as sturdy, we might be able to produce entire frames. Maybe we can execute the production process of carbon fibre bikes in an alternative way, similar to how we use epoxy. This could involve laying down a filament in a semi-cured state and then baking it in an oven. But it's critical to have control over how you lay down the fibres; otherwise, it won't work.

Tailor-Made Performance: Explore St Joris Cycles Today

When people say 3D-printed bikes look fantastic, what should they do first?

They can call or email to schedule an appointment and view the bikes up close. Often, even after a brief explanation of the process, people truly understand how much is involved. It's more of a process than a product, and creating a custom-made bike requires thoughtful choices from the customer.