TPC vs. TPU: Which Flexible Filament Wins?

As a leading provider of high-quality 3D printing materials, we at FormFutura often get asked about the differences between Thermoplastic Copolyester (TPC) and Thermoplastic Polyurethane (TPU). Both are highly elastic and durable, but they serve distinct purposes depending on the application. Understanding their unique properties can help you make the best choice for your 3D printing projects.

What is TPU Filament?

TPU is a widely used flexible filament that offers a combination of elasticity and strength. It has rubber-like properties, which makes it ideal for applications requiring shock absorption, impact resistance, and flexibility. TPU is available in different shore hardness levels, allowing users to select the right degree of softness for their needs.

Key Advantages of TPU:

-

Ease of Printing: TPU is relatively easy to print with most standard 3D printers equipped with a direct-drive extruder.

-

High Flexibility: It provides great stretchability while maintaining strength and durability.

-

Good Chemical Resistance: TPU resists oils, greases, and certain chemicals, making it suitable for industrial applications.

-

Abrasion Resistance: It withstands wear and tear, making it ideal for parts like gaskets, phone cases, and protective covers.

What is TPC Filament?

TPC, or Thermoplastic Copolyester, is another flexible filament with superior performance characteristics, especially in demanding environments. It offers enhanced temperature resistance and UV stability compared to TPU, making it an excellent choice for outdoor applications.

Key Advantages of TPC:

-

Higher Heat Resistance: TPC can withstand higher temperatures compared to TPU, making it suitable for automotive and industrial applications.

-

UV and Weather Resistance: Unlike TPU, TPC is highly resistant to UV degradation, making it ideal for outdoor use.

-

Chemical Resistance: TPC has excellent resistance to oils, fuels, and harsh chemicals.

-

Sustainable Options Available: Some brands offer bio-based or partially recyclable TPC filaments, contributing to environmentally conscious manufacturing.

Differences in 3D Printing Performance

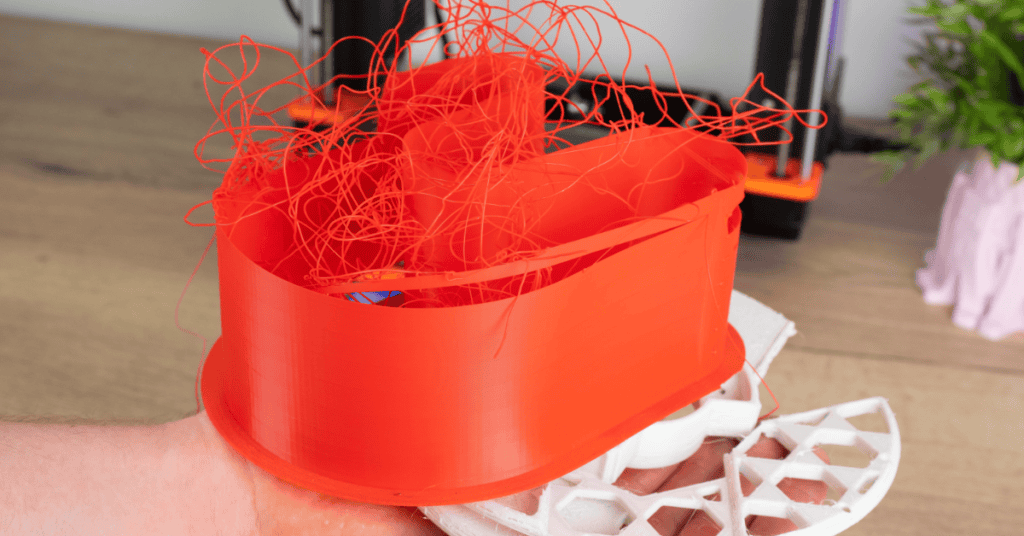

When it comes to 3D printing, TPU is generally easier to work with due to its lower stiffness and higher flexibility. It prints smoothly with minimal warping and adheres well to the print bed. However, TPU can be more prone to stringing and may require careful tuning of retraction settings to achieve optimal results.

TPC, on the other hand, requires higher printing temperatures and better control over extrusion due to its slightly more rigid nature. While it offers superior heat and chemical resistance, it demands a well-calibrated 3D printer with optimized cooling and bed adhesion settings. This makes TPC more suitable for experienced users or applications where TPU might not perform adequately.

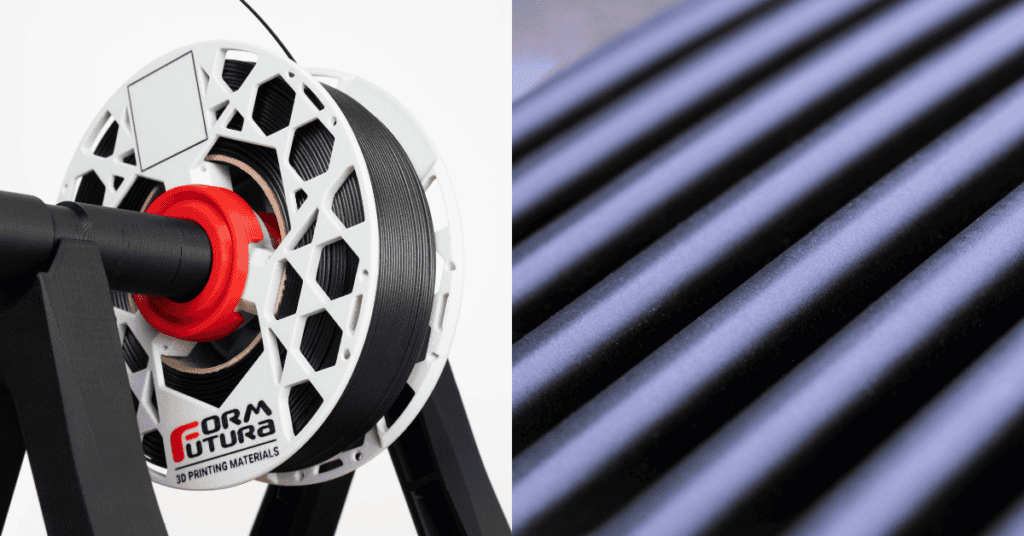

Printing Flexible Filaments is Easier Than Ever

Thanks to advancements in 3D printing technology, printing flexible filaments like TPU and TPC is now more accessible than ever. Modern 3D printers, such as Bambu Lab, Prusa, and Creality models, come equipped with advanced direct-drive extruders, precise temperature controls, and improved bed adhesion, making flexible filament printing far less challenging than in the past. Features like automatic flow calibration and enhanced retraction settings help minimize common issues like stringing and oozing, allowing for smoother and more consistent prints. Whether you’re using TPU for soft, impact-resistant parts or TPC for high-performance applications, today’s printers make achieving high-quality results easier than ever.

Which One Should You Choose?

The decision between TPU and TPC depends on your application needs:

-

If you need a general-purpose, easy-to-print flexible filament with good impact resistance, TPU is a great choice.

-

If your application involves exposure to high temperatures, harsh environments, or prolonged outdoor use, TPC is the better option due to its enhanced durability and weather resistance.

The Best Flexible Filament Options

At FormFutura, we are proud to offer Python Flex TPU and FlexiFil TPC, two exceptional flexible filaments tailored to meet the highest performance standards. Python Flex TPU, our premium TPU-based filament, delivers outstanding printability with exceptional flexibility, making it perfect for wearables, protective parts, and functional prototypes. Meanwhile, FlexiFil TPC, our high-performance TPC filament, ensures superior resistance to environmental factors, ensuring longevity and reliability in demanding applications.

By selecting the right filament for your specific project, you can achieve the perfect balance of flexibility, durability, and ease of printing. Whether you opt for TPU or TPC, knowing the strengths of each material ensures that you get the best results from your 3D printing endeavors. Explore our range of flexible filaments and experience the FormFutura difference!