Revolutionizing Footwear with 3D Printing: A Leap Forward in Comfort and Efficiency

In the fast-paced world of footwear design and manufacturing, innovation is key to staying ahead. One company, LutraCAD B.V., has embraced cutting-edge technology to revolutionize their approach to crafting custom orthopedic footwear. By combining their unique software and 3D printing, this has not only streamlined their production process but also opened up new avenues of creativity and efficiency.

About LutraCAD

Founded by twin brothers Niels and Jordy den Otter, LutraCAD B.V. started as a modest venture. Jordy, a skilled architectural draftsman, joined the orthopedic industry as a footwear designer due to a lack of opportunities in his original field. Meanwhile, Niels brought his expertise in technical informatics to the table. This partnership between the two brothers laid the foundation for a business that would transform the way custom orthopedic footwear is created.

Traditionally, crafting orthopedic shoes and insoles was a laborious process involving meticulous carving and sanding of materials. However, as the demand for custom footwear grew, LutraCAD B.V. realized the need for a more efficient approach. This led them to explore the world of 3D scanning and printing.

The advantages of 3D scanning and printing in the orthopedic industry are multifold. With traditional methods, crafting orthopedic footwear was time-consuming, involving multiple steps and skilled labor. 3D scanning and printing streamlined the process, allowing for quicker production and reduced labor costs.

Moreover, the ability to design and print in three dimensions opened up new possibilities for creative design, enabling LutraCAD B.V. to create intricate and personalized footwear that perfectly fit their clients’ needs.

Perhaps the most significant benefit of 3D scanning and printing for LutraCAD B.V. is the precise measurements’ 3D scanners can produce. These scans, combined with their dedicated software, allow for highly accurate and customizable orthopedic footwear. This new way of producing results in a massive reduction in material waste. Unlike milling, where a significant portion of the material is carved away, 3D printing uses only the exact amount of material required for each design. This not only saves costs but also aligns with sustainable manufacturing practices—a crucial consideration in today’s environmentally conscious world.

LutraCAD B.V.’s journey into 3D printing has been guided by a commitment to quality, innovation, and customer satisfaction. By partnering with FormFutura, they’ve harnessed the power of advanced materials and technology to create orthopedic footwear that meets the highest standards of comfort, functionality, and style. As they continue to push the boundaries of what’s possible in the industry, LutraCAD B.V. is not only transforming the way we think about orthopedic footwear but also paving the way for a future where custom, personalized products are more accessible and efficient than ever before.

As we continued our conversation, it became clear that this innovative company has more in store for the future. While they’ve already made significant strides in revolutionizing the podiatry industry, their ambitions extend beyond just software and product design.

“We’re not just looking at the software aspect,” Niels explained. “We have a vision for more sustainable materials in 3D printing. Many of the materials currently used in the industry are not biodegradable.”

Niels went on to emphasize the importance of sustainability in the industry, especially considering the sheer volume of orthotics produced globally. “There are millions of orthotics being produced each year,” they noted. “Imagine if we could make a positive impact by ensuring that these products are environmentally friendly and can be easily recycled or composted.”

This emphasis on sustainability is not only commendable but also indicative of the company’s commitment to responsible innovation. Like FormFutura they aim to contribute to a greener future for both the podiatry field and the 3D printing industry as a whole.

Challenges and possibilities

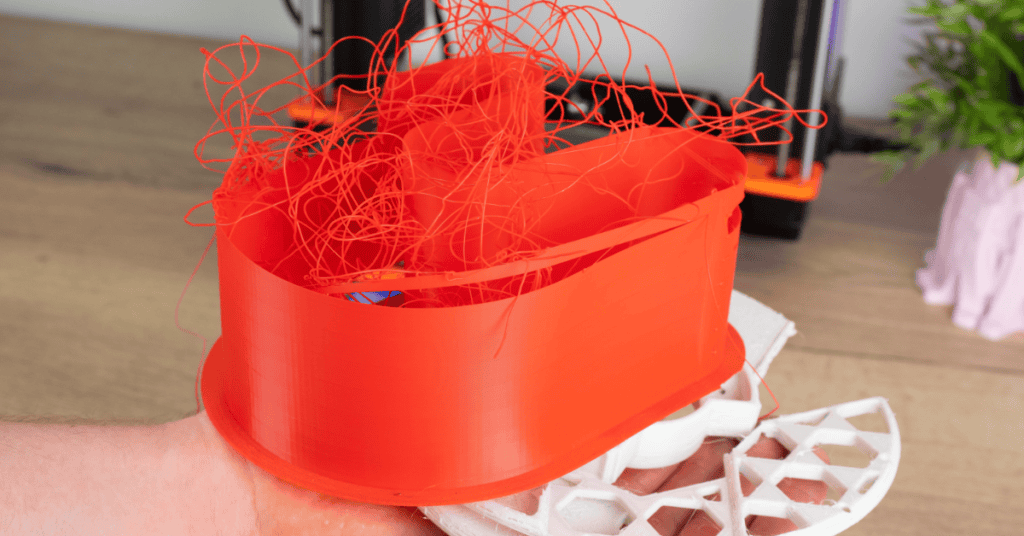

One of the main challenges LutraCAD B.V. faced was the transition from traditional milling techniques to 3D printing. While milling offered speed, 3D printing promised unparalleled precision and reduced waste. However, the shift wasn’t without its hurdles. Printing in three dimensions required the team to experiment with different materials, bed adhesion techniques, and even the orientation of the prints. The aim was to achieve not only high-quality results but also a seamless and user-friendly process.

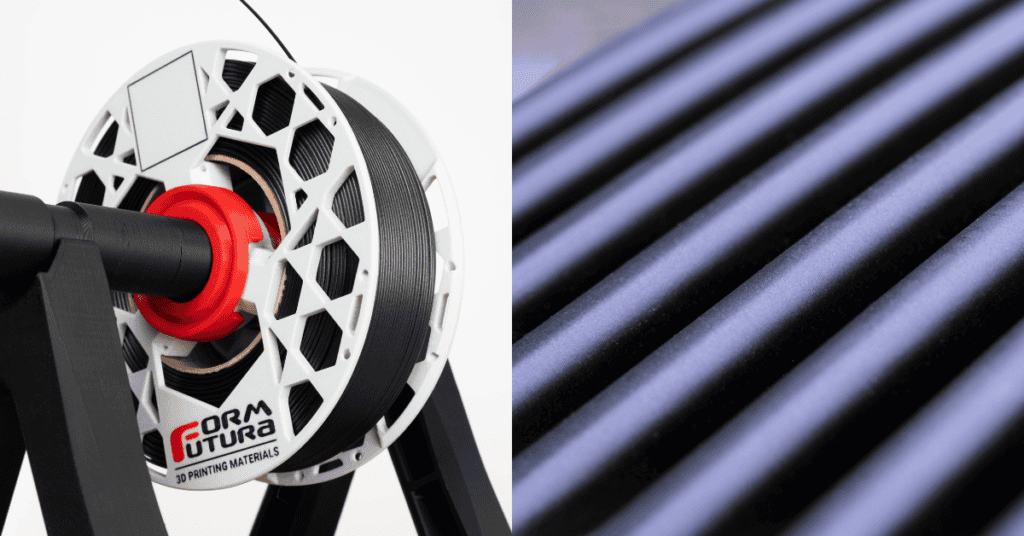

The breakthrough came when LutraCAD B.V. partnered with FormFutura, a leading provider of 3D printing materials. They found that FormFutura Centaur PP (Polypropylene filament) provided the perfect balance of strength, flexibility, and ease of use for their specific applications. This collaboration enabled LutraCAD B.V. to create the perfect software for custom orthopedic insoles and footwear that were not only functional but also comfortable and durable.

Of course, no journey towards innovation is without its challenges. When discussing their future plans, It was acknowledged that the complexities involved in introducing new materials and processes to an established industry. “It’s not just about software; it’s about changing mindsets and practices,” they explained. “But if we can collaborate with like-minded partners who share our vision, we can work together to overcome these challenges.”

Imagine a future where 3D-printed orthotics are not only tailored to each individual but are also made from sustainable materials that can be easily recycled. It’s not just about providing a better product; it’s about contributing to a healthier planet

Niels – LutraCAD B.V.

Collaborate and Innovate

In wrapping up our interview, Niels had a clear message for those interested in their work: If you’re intrigued by the possibilities of 3D scanning and printing similar products or exploring sustainable solutions, we encourage you to reach out to FormFutura or us directly. We’re here to engage in conversations and provide advice on the best materials and solutions that suit your needs.

LutraCAD B.V. focus on an advisory role stands out, as they aim to guide individuals and companies through the process, especially those who may be new to 3D printing. “Our goal is to ensure that anyone interested in our technology feels comfortable and supported,” they added. “If you’re curious or have questions, don’t hesitate to get in touch. Together, we can explore the potential of this innovative approach.”

Conclusion

LutraCAD B.V’s software-driven approach has not only streamlined the process of creating custom orthotics but has also set the stage for more sustainable practices within the industry. As they continue to push the boundaries of what’s possible, it’s clear that their journey is far from over. With their sights set on a future where personalized healthcare meets environmental responsibility, this company is leaving an indelible footprint in the world of podiatry and 3D printing.

As we wrap up this interview, we invite you, the reader, to consider the impact of innovation and collaboration in your own field. Just as this company has forged new paths, what possibilities lie ahead for you? What partnerships could lead to transformative change? As we’ve learned from this remarkable story, the answers might just shape the future in ways we never thought possible.

Contact LutraCAD B.V.

Plein 1969 1A

5473 CA Heeswijk-Dinther

The Netherlands

W https://www.lutracad.com

E info@lutracad.com

T +31 (0)85 018 51 98