Material Guide – PETG Filament

If you have used PETG filament to 3D print, you might agree that it's could be hard to get it exactly right. To help you get started and learn how to print with FormFutura PETG Filament, we wrote this Material Guide - PETG Filament!

By the end of this 3D Printing Material Guide, you'll be armed with all the knowledge about PETG characteristics, printing properties, techniques, subtypes, and how to pick the best one for your unique project!

The Stars of the Show

PETG filament is a winning combination of user-friendliness and print-capabilities, making it a great choice for both beginners and experienced 3D printers.

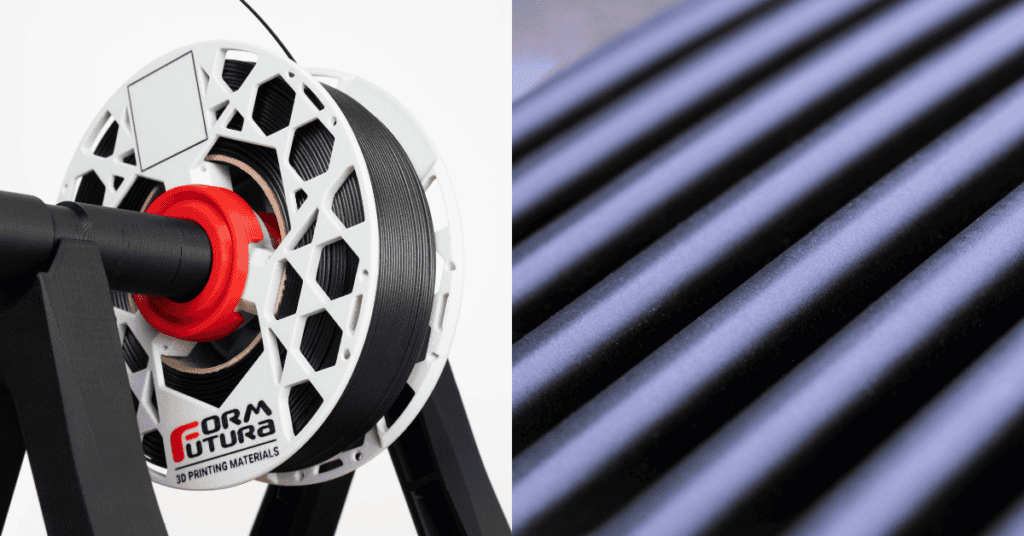

ReFill PETG - Our most sustainable 3D printing PETG filament. This PETG filament is designed for use with our ReFill Flanges. This filament reduces your carbon footprint to a minimum while maintaining its high quality.

EasyFil ePETG - The wallet friendly alternative. This Go-To PETG Filament is available for €22.49 per kilo and high speed printing compatible! Thanks to its characteristics, and its low entry price, it is the best choice for beginning 3D print enthusiasts!

HD Glass - This Heavy Duty (HD for short) PETG filament has outstanding properties when you're looking for strength, toughness and temperature resistance. This PETG filament is available in 2 variants: Full colour or translucent.

ReForm rPET - Made from waste-, rest-, and recycled materials, ReForm rPET is a king of sustainability. ReForm rPET is a high-quality, versatile filament used in a wide range of applications.

High Precision PET - If you're looking for the perfect 3D printing Filament with high consistency throughout the whole filament? Then don't look further than High Precision PET. This unique filament is laser tested for it's ovalidity, shrinkage, and color tolerances.

Characteristics

Superb Strength and Resilience: PETG is renowned for its impressive strength and resilience, making it an excellent choice for functional parts that require durability. With a high resistance to impact and deformation, PETG components maintain their integrity even under stress.

Effortless Printability: FormFutura's PETG filament boasts excellent printability, adhering reliably to the print bed and minimizing the risk of warping during the printing process. Its smooth flow characteristics ensure consistent extrusion, resulting in high-quality prints with minimal hassle.

Printing Settings: For optimal results, it is recommended to print FormFutura's PETG filament within a temperature range of 230°C to 260°C, with a print speed ranging from 40 to 60 mm/s. These settings ensure reliable adhesion and smooth layering, producing top-notch prints every time.

Compatible with Direct Drive Extruders: To maximize performance and minimize printing issues, a direct drive extruder setup is recommended for handling FormFutura's PETG filament. This configuration provides precise filament control, preventing any potential bending or curling during printing.

Chemical Resistance and Stability: FormFutura's PETG filament offers excellent resistance to chemicals, oils, and greases, ensuring long-term stability and durability in a variety of environments. Whether used indoors or outdoors, PETG prints maintain their integrity, making them suitable for a wide range of applications.

Versatile Temperature Tolerance: With its ability to withstand a broad temperature range, FormFutura's PETG filament is suitable for applications requiring resilience in diverse conditions. From low temperatures to high, PETG prints retain their strength and functionality, making them ideal for a multitude of projects.

Pro's and Con's

![]() High durability and impact resistance

High durability and impact resistance

![]() Good chemical resistance to oil and grease

Good chemical resistance to oil and grease

![]() Easy to print, minimal warping

Easy to print, minimal warping

![]() Transparent/Translucent aesthetics

Transparent/Translucent aesthetics

![]() Hydroscopic nature requiring to dry the filament

Hydroscopic nature requiring to dry the filament

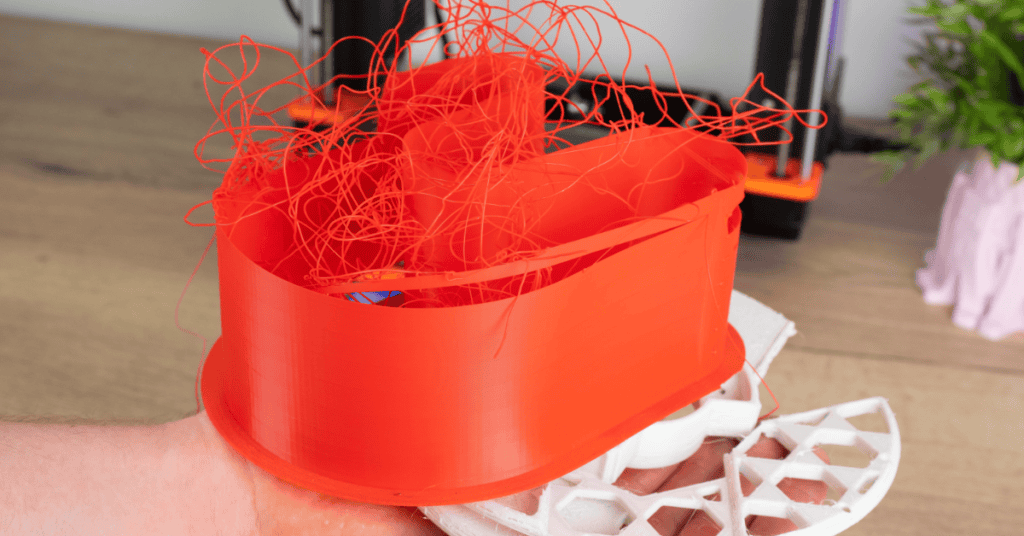

![]() Stringing and oozing, post-processing necessary

Stringing and oozing, post-processing necessary

![]() Brittleness could cause layer delamination

Brittleness could cause layer delamination

![]() Limited Temperature resistance

Limited Temperature resistance

PETG Print Settings*

Nozzle Size: ≥ 0.1 mm

Bed Temperature: ± 70 – 90° C

Print speed: Medium / High

Nozzle Tempeature: ± 230 – 260° C

Filament Drying: Required**

First Layer Cooling: No

Layer Cooling: 20-50%

Enclosure: Optional

*These are general guidelines, for specific print settings, please refer to the product page.

**Don't skip the drying step! PETG is prone to absorbing moisture from the air, which can lead to printing problems like bubbles and weak layers. To ensure successful prints, thoroughly dry your PETG filament for at least 24 hours at 50°C (122°F) before printing. You can even keep the filament drying while printing for optimal results.

Tips for Printing PETG

Keep PETG filament dry: Store your PETG filament in a dry place, preferably in a sealed bag with desiccant or silica gel, to prevent moisture absorption and air bubbles in your 3D prints.

Heated bed: If printing without a heated bed, use painter’s tape or adhesive spray to ensure good first layer adhesion. Poor adhesion can lead to cracking when the object is flexed or stretched.

Direct drive extruder: For optimal PETG printing, use a direct drive extruder that provides adequate support for the filament, preventing it from bending or being pushed in the wrong direction.

If using a Bowden extruder: Ensure the filament does not get stuck against the Bowden tube wall.

Disable or limit retraction: Disable or minimize retraction to max ± 5mm for TPU printing, as excessive retraction can cause filament jams.

Printer settings: Adjust printer settings specifically for the filament you’re using before printing with PETG. Use the settings from this blog and experiment what works best for your 3D printer!