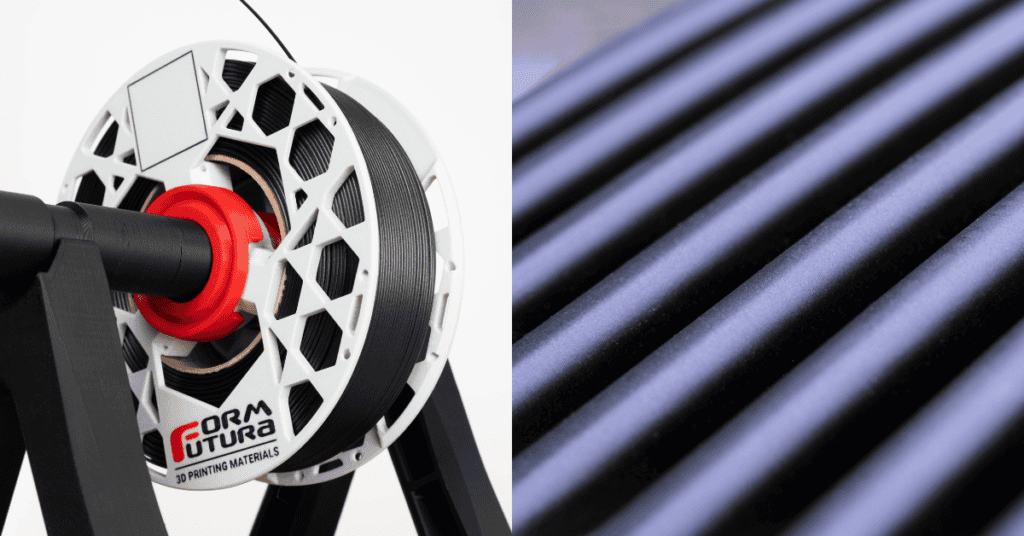

Multi-material 3D printing takes 3D printing beyond just color variations. It allows you to use two or more filament spools to create objects with distinct functionalities within the same print. Traditionally, this required complex slicer settings adjustments. However, advancements like the Bambu Labs AMS station have revolutionized the process.

These stations hold up to four spools each, and a single Bambu Labs printer can connect to four AMS stations, providing access to a whopping 16 unique filaments in a single print! This opens exciting possibilities, but what happens when you combine entirely different materials like PETG and TPU?

To delve into this, we'll explore the topic in this Multi Material Guide – PETG & TPU in a two-part blog series. We'll answer these key questions:

- Part 1: Printing PETG and TPU Together – Key Considerations: We'll discuss the important factors to keep in mind when using these specific materials together.

- Part 2: Setting Up and Printing Success – This part will guide you through setting up your multi-material station for optimal PETG and TPU printing, along with addressing common challenges and solutions.

Understanding PETG and TPU

To get a better understanding if it's possible to use multi materials in the same 3D print, we need to first understand the characteristic of the materials we are using.

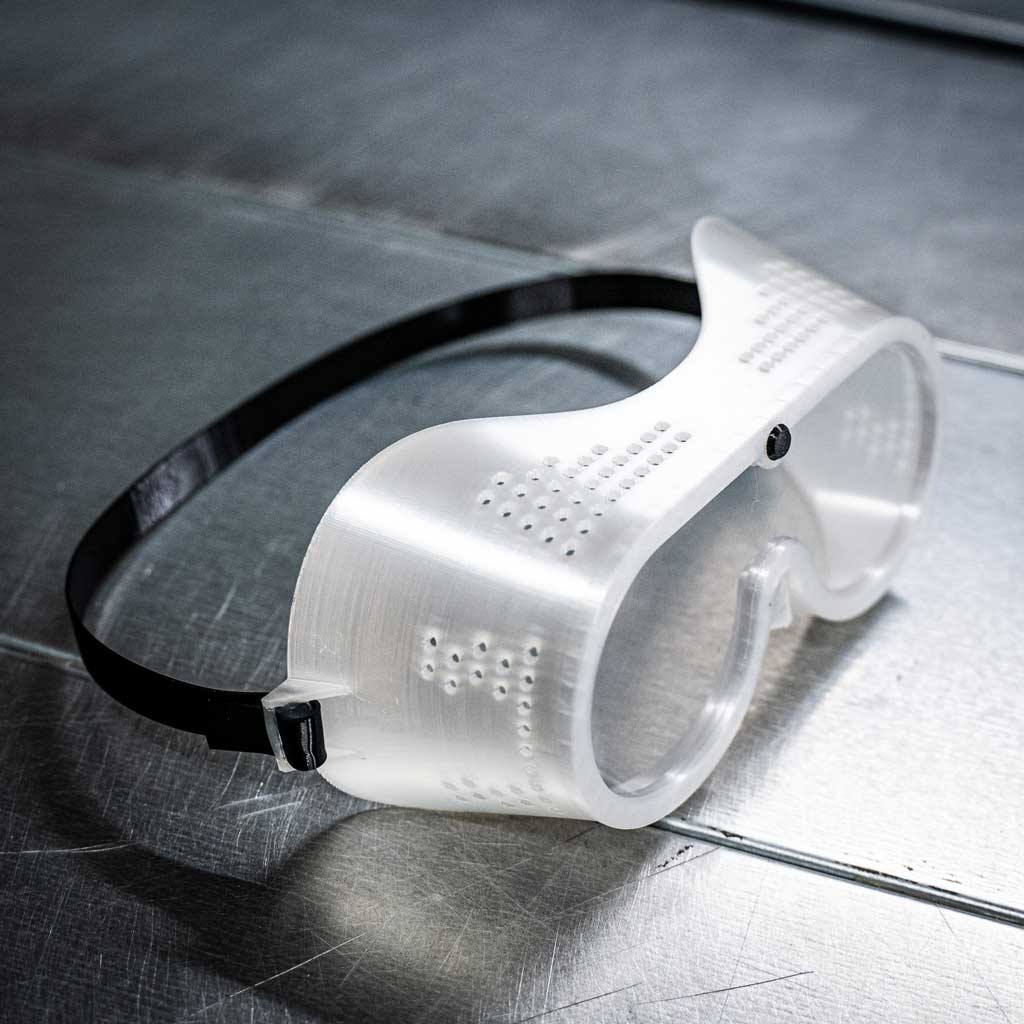

For this blog, we are looking and comparing our HDglass PETG and our Python Flex 98A TPU filaments.

- Extremely transparent and high gloss

- Easy to print

- Compatible for printing at high speed

- High strength and toughness compared to similar materials

- Watertight printing

| Nozzle size: ≥ 0.15mm |

| Layer height: ≥ 0.1mm |

| Flow rate: ± 100% |

| Print temp: ± 235 – 260° C |

| Print speed: Medium |

| Retraction: Yes ± 5mm |

| Heat bed: ± 80 – 90° C |

| Fan speed: 10 – 30% |

| Experience level: Beginner |

Python Flex TPU

Python Flex TPU 98A is a flexible type of 3D printer filament with a shore hardness of 98A and is perfect for 3D printing strong and resilient parts that require flexibility and elasticity.

Properties and characteristics

- Perfect combination of strength, flexibility and elasticity

- Easy to print

- Compatible for printing at high speed

- Watertight printing possible with only single wall prints

- Excellent resistance to oil, greases, microorganisms and abrasion

- Improved flowing behaviour and inter-layer adhesion

| Nozzle size: ≥ 0.25mm |

| Layer height: ≥ 0.1mm |

| Flow rate: ± 110 – 130% * |

| Print temp: ± 220 – 250° C * |

| Print speed: Medium-Fast |

| Retraction: Yes ± 5mm |

| Heat bed: ± 0 – 60° C |

| Fan speed: 50-100% |

| Experience level: Intermediate |

Compatibility and Similarities of PETG and TPU

While both HDglass PETG and Python Flex 98A TPU are suitable for 3D printing, they cater to different needs. However, there are some key similarities that make them potentially compatible for multi-material printing in certain situations.

Similarities:

- Ease of Printing: Both filaments are advertised as easy to print, making them good options for beginners or those new to multi-material printing.

- High Speed Printing: Both PETG and TPU can be printed at medium to medium-fast speeds, allowing for efficient printing processes.

- Watertight Printing: Both materials can create watertight prints, even with single walls for TPU, which is a valuable feature for functional parts.

Limited Compatibility:

Due to their inherent material properties, PETG and TPU likely wouldn't be ideal for directly printing together in a single object. They have some key differences:

- Flexibility: PETG offers high strength and toughness, but with limited flexibility. TPU excels in flexibility and elasticity. Combining them might result in weak bonding between the rigid and flexible areas.

- Print Temperature: While their temperature ranges overlap slightly, TPU generally requires a slightly cooler printing temperature than PETG. This could lead to printing inconsistencies if attempting to use them simultaneously.

The Verdict on PETG and TPU

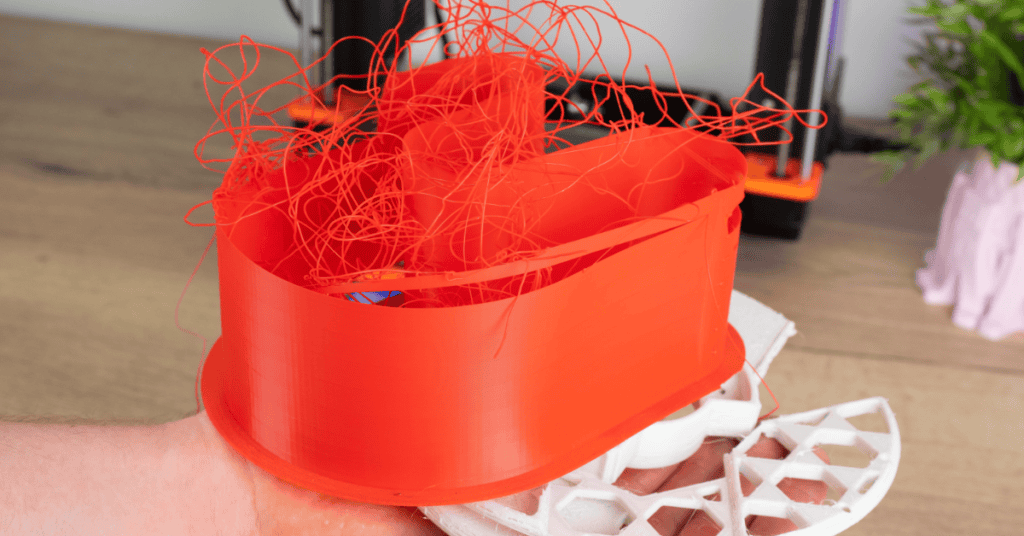

While combining materials like PETG and TPU offers exciting possibilities for creating multi-functional objects, our experiment revealed a significant hurdle – achieving proper interlayer adhesion.

The vast difference in their printing characteristics prevented the layers from fusing effectively. In our attempt with a HueForge print inspired by the Fallout series, the desired outcome wasn't achieved.

While our initial test in this Multi Material Guide – PETG & TPU presented an adhesion challenge, don't be discouraged! Multi-material printing offers a vast realm of possibilities, and with the right approach, even these seemingly incompatible materials can be used effectively.

Stay tuned next week for part 2 of this blog, where we'll explore techniques to optimize printing with PETG and TPU, troubleshoot common issues, and showcase how to successful 3D print objects with this material combination!

In the meantime, we'd love to hear from you! Have you experimented with multi-material printing using PETG and TPU? Share your experiences, tips, and any questions you may have on social media by tagging our account @FormFutura!